Device for rapidly depositing diamond-like carbon film

A diamond thin film, fast technology, applied in the direction of metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of reducing film deposition rate, product yield, complexity, etc. The effect of increasing plasma density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

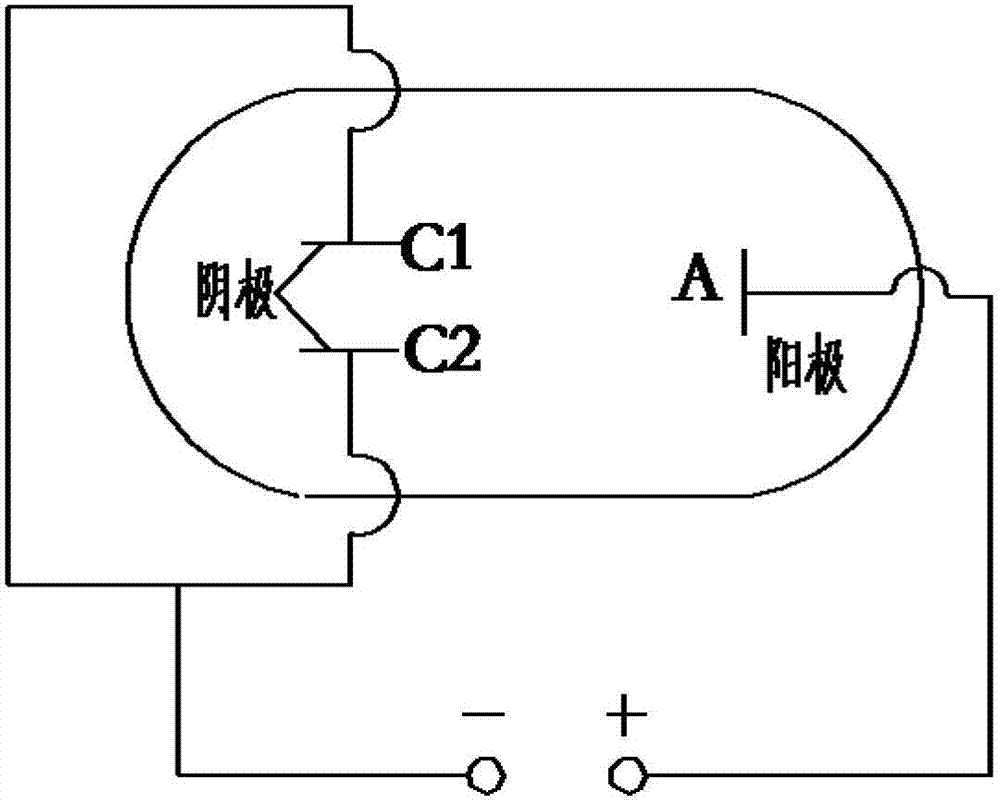

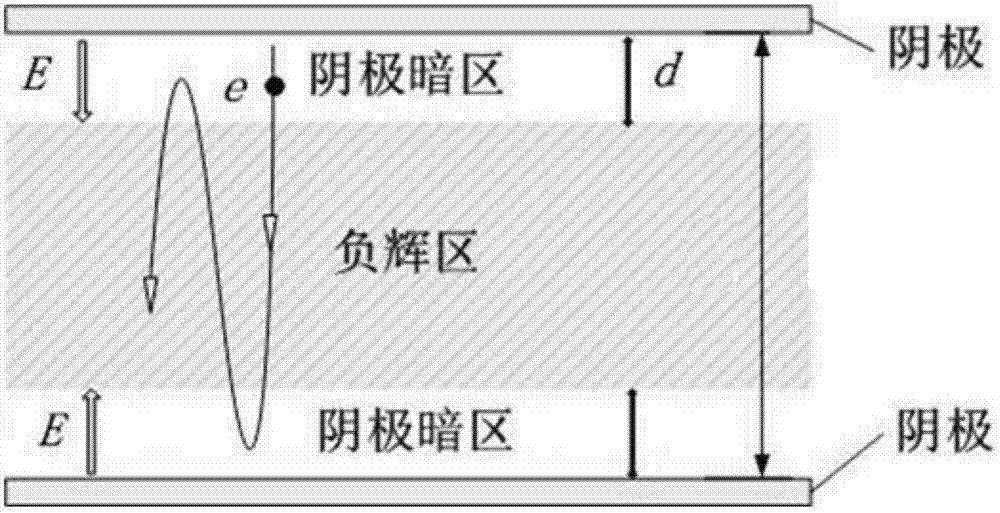

[0034]When the present invention is specifically implemented, a set of parallel plate hollow cathodes with the same external dimensions is designed. The diameter of the upper and lower plates can be determined according to the size of the original vacuum chamber, and a gas path interface is provided on one side of the plates, the gas is supplied through one of the plates, and the substrate is placed on the other plate. Among them, the lower plate is installed on the rotating bracket (the rotating bracket is driven by the motor), and the gas is supplied from the vent of the vacuum chamber. The upper and lower plates are connected by three length-adjustable screws. By adjusting the matching nuts, the distance between the two pole plates can be adjusted. The hollow cathode devices are powered by connecting the radio frequency power supply through the lower plate.

[0035] Figure 3(a) shows the different deposition rates under different working conditions in the flat-plate RF ho...

Embodiment 2

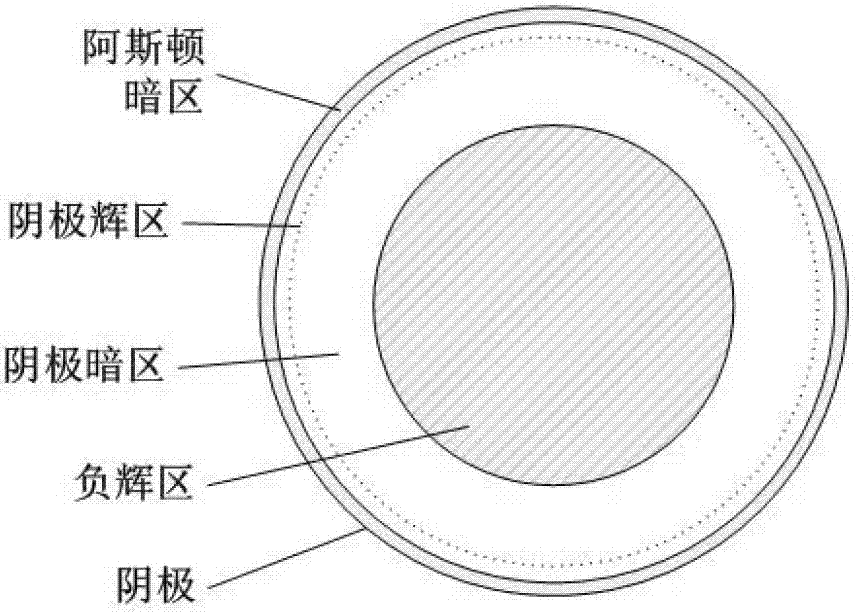

[0037] When the present invention is implemented, a cylindrical hollow cathode system is designed. Any section of the cylinder is used as a gas inlet, and the gas is fed into the cylinder through this end, and the power supply is connected to the wall of the cylinder, and the hollow cathode system is connected to the radio frequency power supply for power supply; the ratio of the length and diameter of the cylinder is less than 12, Within this range, the diameter and length of the metal cylinder are adjustable.

[0038] Figure 3(b) shows the different deposition rates under different working conditions in the cylindrical radio frequency hollow cathode and radio frequency plasma enhanced chemical vapor deposition systems, among which the radio frequency hollow cathode system The diameter of the cylinder d=10-150 mm. The discharge gas is high-purity argon, the gas flow rate is 15-60 sccm, and the working pressure is 0.1-10 Pa. It can be seen from the figure that under the cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com