Discharging electrode structure generated by vacuum plasmas based on magnetic field effects

A plasma and discharge electrode technology, applied in the direction of plasma, electrical components, etc., can solve the problems of rapid decrease of axial energy and low plasma density, and achieve the effect of ensuring effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

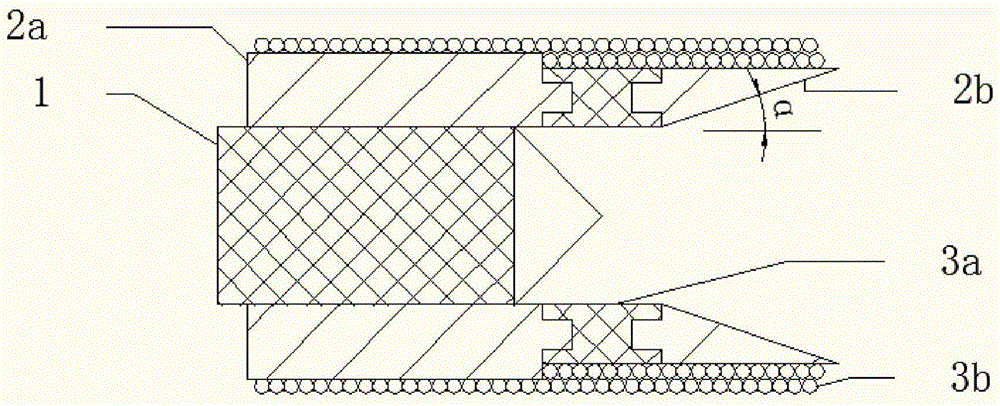

[0025] figure 1 It is a two-dimensional schematic diagram of the structure of the discharge electrode embodiment of the present invention. see figure 1 , In this embodiment, the discharge electrode includes a cathode 1 with a conical end, a ring-shaped anode 3a, a solenoid-shaped anode 3b, a cylindrical insulating member 2a, and a horn-shaped insulating member 2b.

[0026] Wherein, the cathode 1 is a structure with a conical cone at one end, and the cone is used as the discharge end of the cathode 1 . By setting the cone end as the discharge end, the discharge effect can be enhanced, and the plasma can appear in the center of the electrode, which is convenient for magnetic field confinement control, but the tip of the cone should not be too sharp, otherwise it will cause the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com