Preparation method of high-aspect-ratio light trapping structure for surface of silicon thin film battery

A light-trapping structure and high aspect ratio technology, which can be used in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor fidelity effect, affecting the improvement of battery efficiency, high cost of laser etching glass and not suitable for mass production needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific examples.

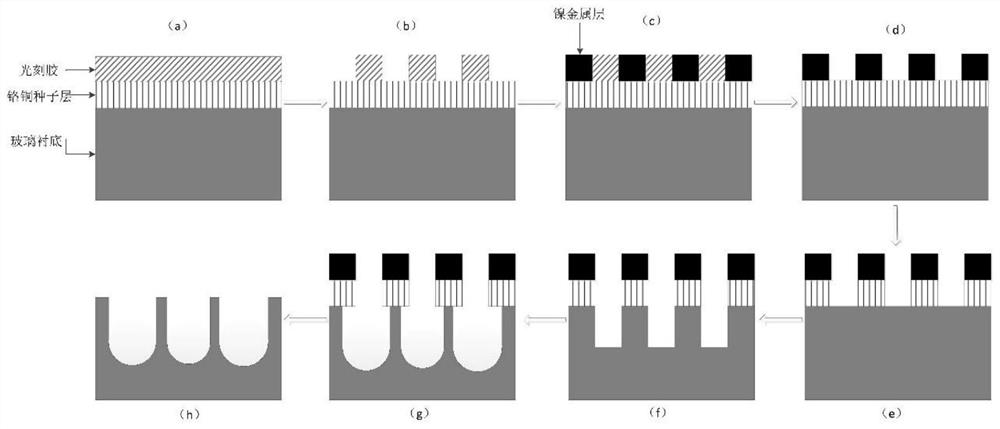

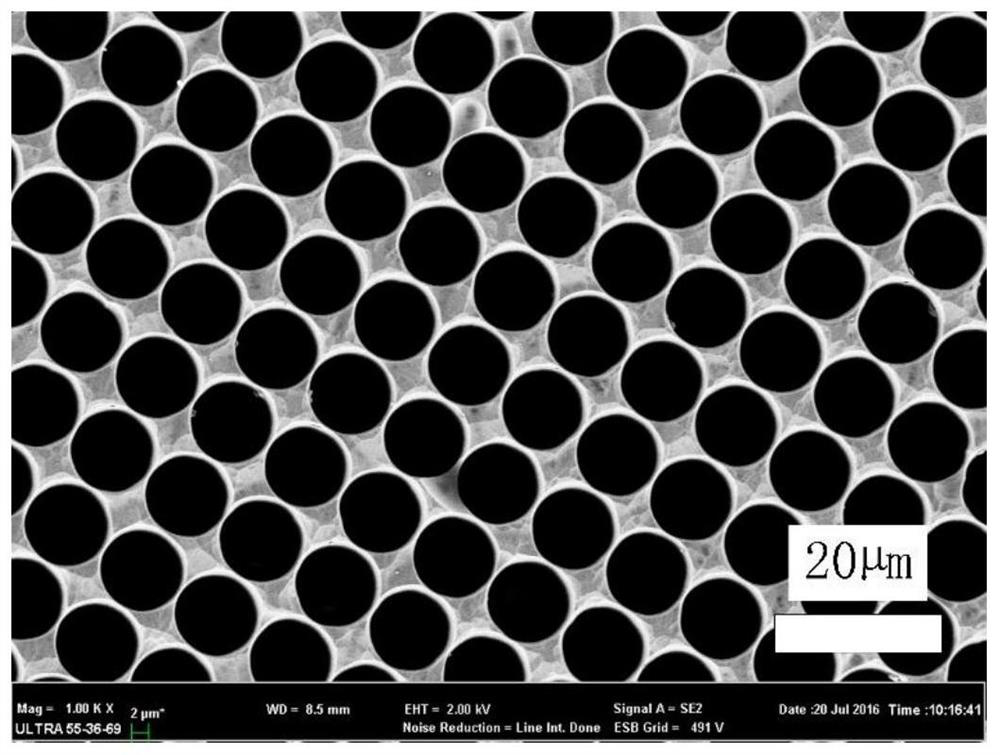

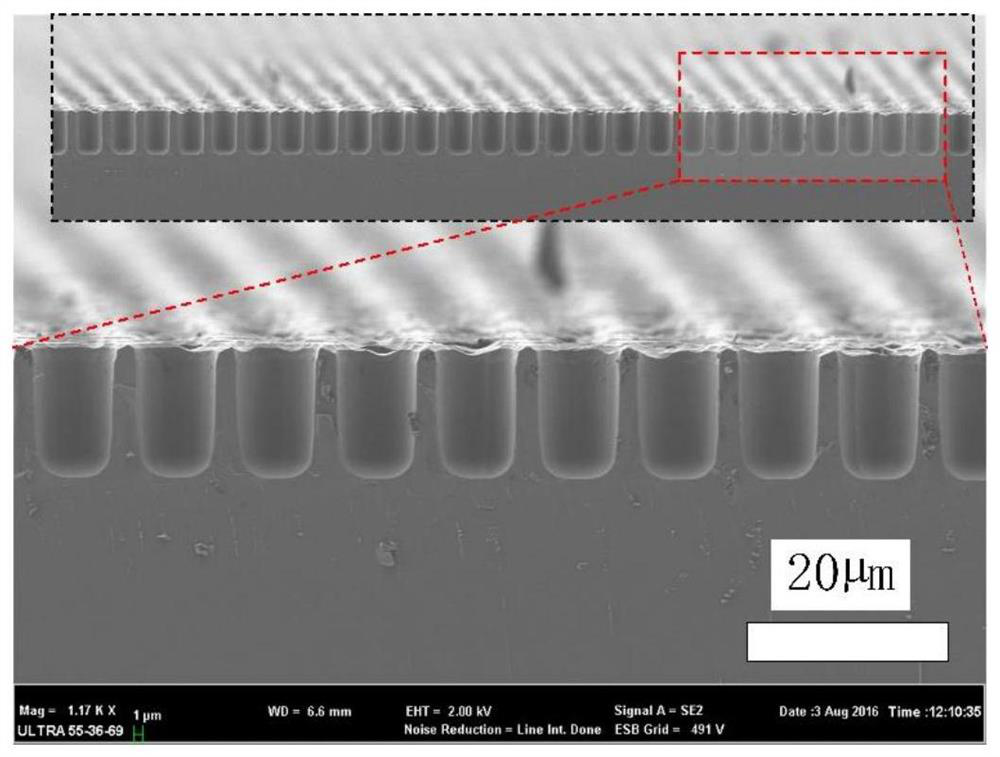

[0036] figure 1 An example of preparing a pit array structure with a high aspect ratio on a glass surface by using a dry-wet method is given. Using a negative photolithography plate, the technological process of forming an array structure of high, deep and wide pits on the surface of a glass substrate is as follows: (a) sputtering a metal seed layer and spin-coating a photoresist. The present invention adopts Cr / Cu (50nm / 150nm) combination. That is, first sputter a 50nm Cr metal layer on the glass surface, and then sputter a 150nm Cu metal layer on the Cr metal layer. Spin coating 3-5μm photoresist, positive resist; (b) photolithography, development. Using 415nm ultraviolet light, photolithography in SUSS double-sided alignment contact lithography, then developing, and finally baking in an oven; (c) electroplating Ni metal. On the Cr / Cu metal seed layer, a 2-3 μm Ni metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com