Plasma flat-plate light source

A flat light source, plasma technology, applied in the direction of gas plasma lamps, etc., to achieve the effect of increasing luminous efficiency, improving luminous efficiency and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

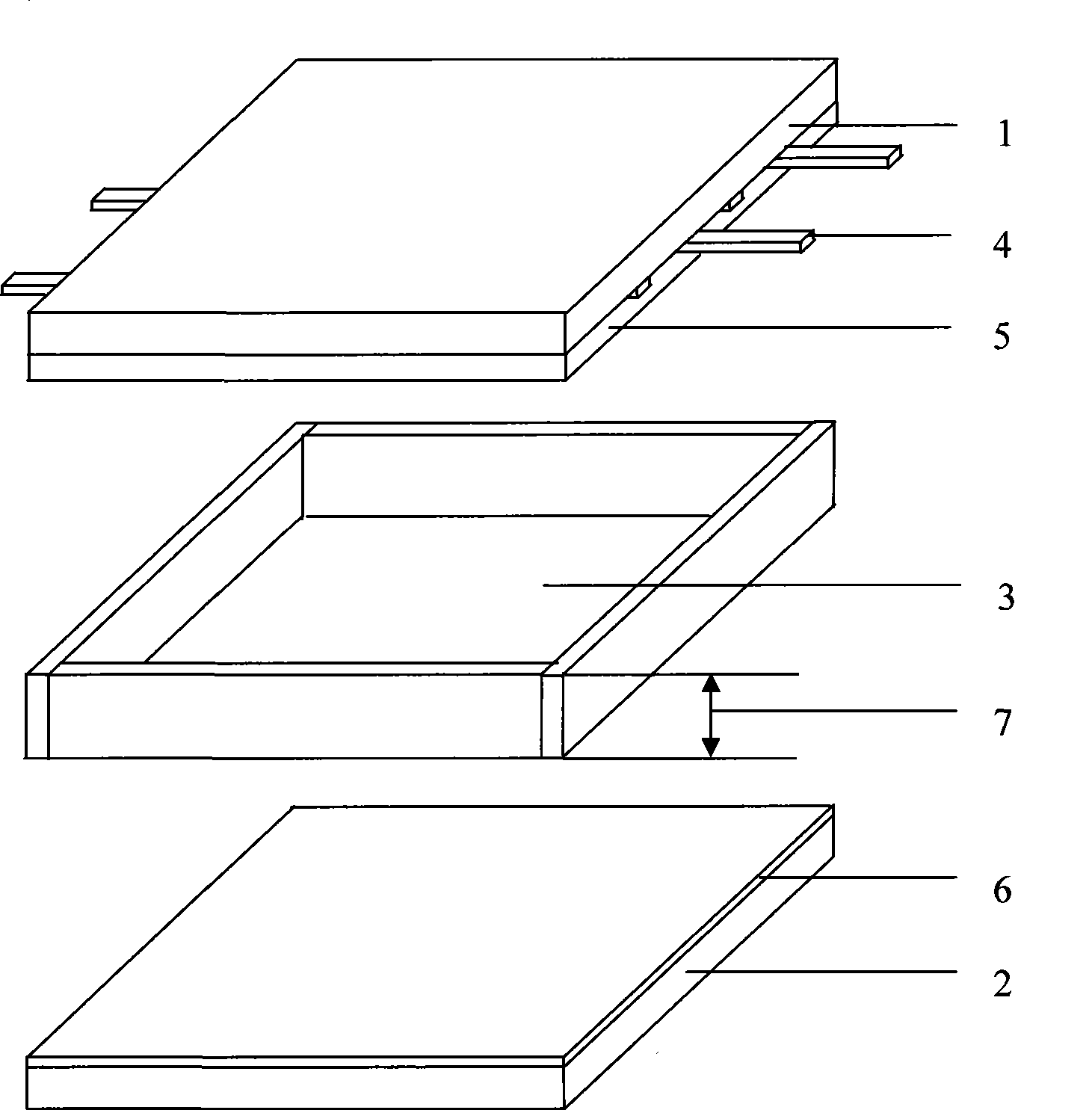

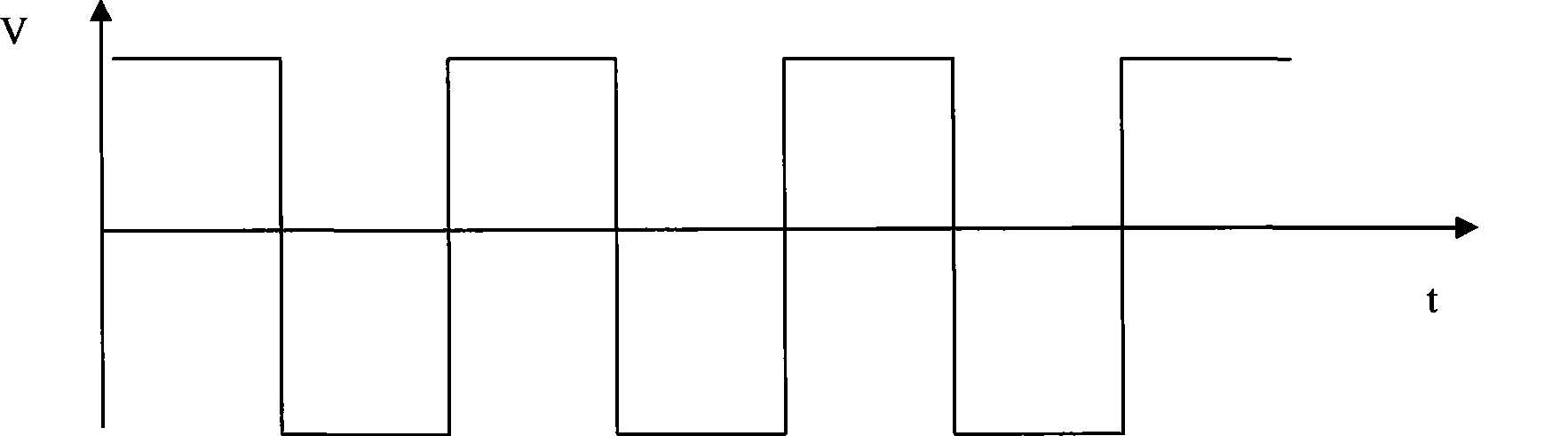

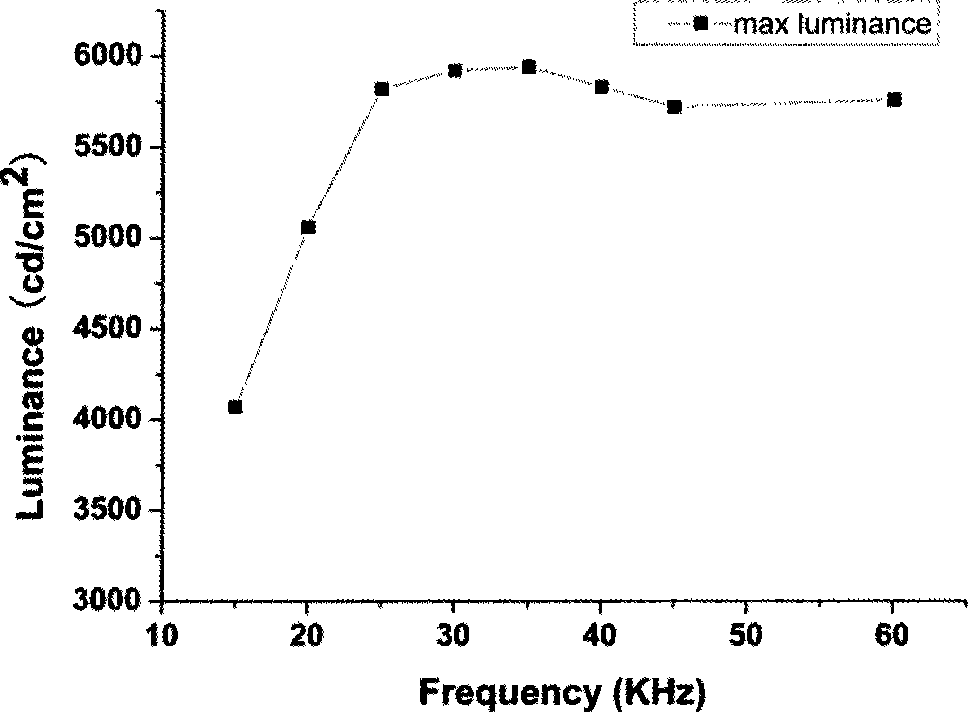

[0021] Embodiment 1, the structure of the plasma flat panel light source adopting the new discharge mode is as follows figure 1 As shown, it includes a front substrate 1 and a rear substrate 2, a discharge chamber 3 is provided between the front substrate and the rear substrate, parallel electrodes 4 are arranged on the front substrate, and the electrode spacing is 3 mm to 10 mm, and the electrode layer is covered with a transparent medium layer and Protective film 5, the rear substrate is coated with a mixed layer 6 of three-color phosphors to emit white light, the distance 7 between the front and rear substrates is 0.7 mm to 1.5 mm, and the working gas filled in the discharge cavity is a mixed gas of Ne and Xe gases, of which The proportion of Xe is equal to 20%, and the pressure of the working gas is 400-700 Torr. A low-frequency square wave trigger driving waveform such as figure 2 As shown, the above-mentioned plasma flat panel light source is driven to obtain the worki...

Embodiment 2

[0023] Embodiment 2, the structure of the plasma flat panel light source adopting the new discharge mode is as follows figure 1 As shown, the parallel electrodes on the front substrate 1 are electrodes 9 with planar protrusions, such as Figure 5 As shown, other conditions remain unchanged, when the low-frequency square wave is triggered to drive the plasma flat panel light source, the working mode of positive column discharge is also obtained, and the working principle is the same as that of the first embodiment.

Embodiment 3

[0024] Embodiment 3, when the Xe ratio is higher than 20%, up to 100% pure Xe gas, under the drive of low frequency square wave, the working mode of positive column discharge is also obtained, but the optimal frequency varies with the Xe ratio. The working principle is the same as that of Embodiment 1, and constitutes a group of embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com