Preparing method of high active selenium source for selenylation, apparatus and applications

A high-activity, selenium source technology, applied in binary selenium/tellurium compounds, chemical industry, elemental selenium/tellurium, etc., can solve the problems of selenium material waste, inhomogeneity, and difficult reaction, etc., and achieve photoelectric conversion efficiency improvement, Ease of transportation and storage, and the effect of saving selenium raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

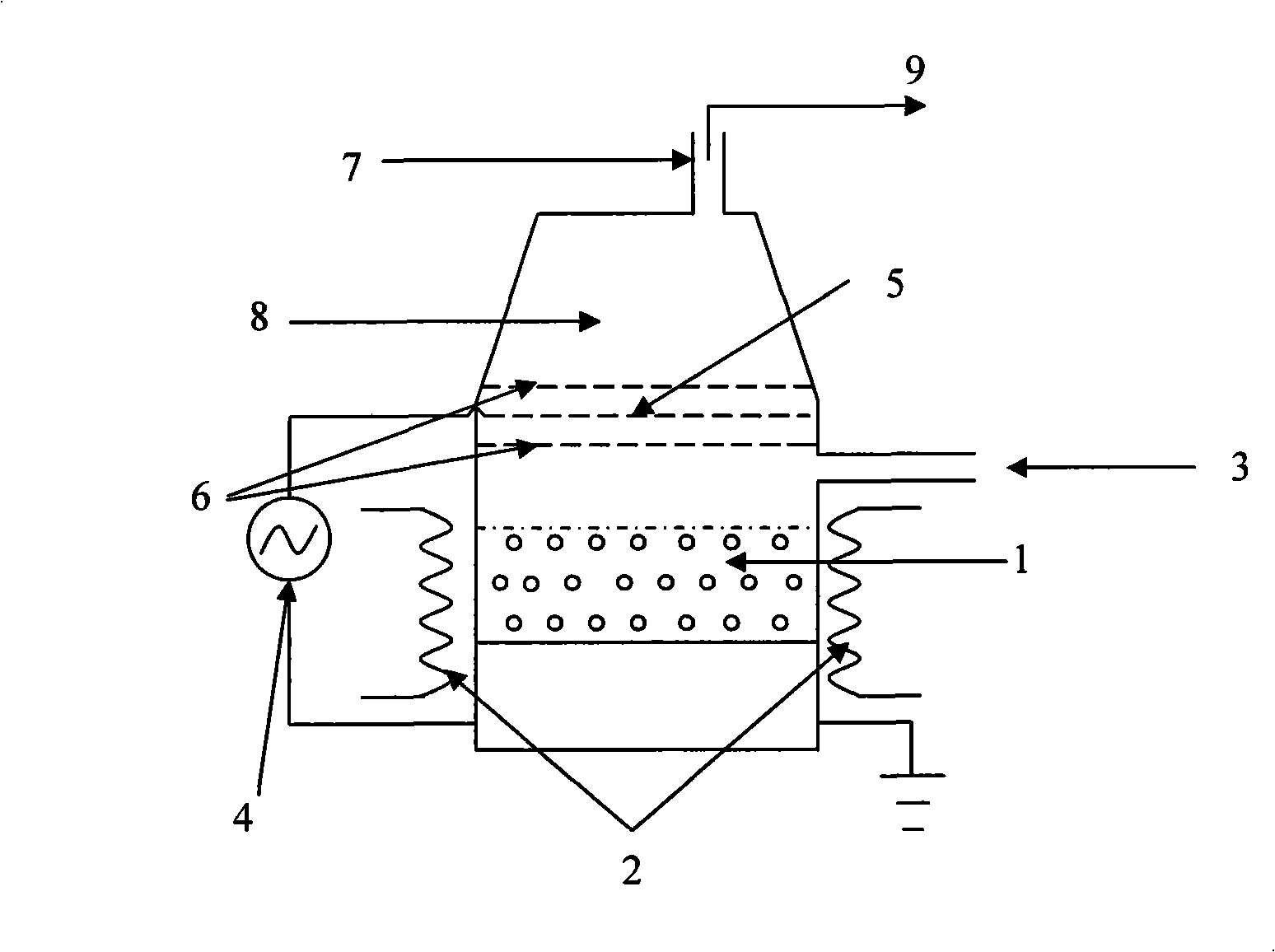

[0026] Embodiment 1. A selenium source generating device used in a method for generating a highly active selenium source

[0027] Such as figure 1 As shown, the device includes a closed reaction tank. A solid selenium source 1 is placed in the lower part of the reaction tank. The outer circumference of the reaction tank corresponds to the solid selenium source as a heating device 2. It can be heated by resistance wire or by any other heating device. The device is provided with a gas input port 3 for introducing hydrogen or a mixed gas of hydrogen and argon on the side wall of the reaction tank above the solid selenium source, and an excitation power source 4 is provided in the reaction tank above the gas input port The anode glow electrode 6 and the cathode glow electrode 5 are connected. The part of the reaction tank above the glow electrode constitutes the hydrogen selenide reaction chamber 8. The top of the reaction tank is provided for outputting selenium to the selenization ...

Embodiment 2

[0029] Example 2. Method for producing high-activity selenium source for selenization treatment

[0030] The method includes:

[0031] First, the solid selenium is heated and evaporated to produce selenium vapor; the heating and evaporation temperature is 220°C.

[0032] Second, hydrogen is incorporated into the selenium vapor generated in the upper step.

[0033] Third, perform plasma glow decomposition and synthesis of the mixed gas in the previous step to obtain hydrogen selenide and a highly active solid selenium-selenium atmosphere.

[0034] A 13.56MHz AC power source is used to generate plasma to ionize the gas, thereby decomposing the chain of selenium atoms in the selenium vapor, causing the selenium atoms to react with hydrogen to produce hydrogen selenide, and monoatomic selenium in a highly active selenium atmosphere.

Embodiment 3

[0035] Embodiment 3. Method for producing highly active selenium source for selenization treatment

[0036] The method includes:

[0037] First, the solid selenium is heated and evaporated to produce selenium vapor; the heating and evaporation temperature is 550°C.

[0038] Second, hydrogen or a mixed gas of hydrogen and argon is incorporated into the selenium vapor generated in the upper step; the gas flow ratio of the incorporated hydrogen and argon is 1:10.

[0039] Third, perform plasma glow decomposition and synthesis of the mixed gas in the previous step to obtain hydrogen selenide and a highly active solid selenium-selenium atmosphere.

[0040] A 50KHz AC power source is used to generate plasma to ionize the gas, thereby decomposing the chain of selenium atoms in the selenium vapor, causing the selenium atoms to react with hydrogen to produce hydrogen selenide and monoatomic selenium in a highly active selenium atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com