Slotted electrode for high intensity discharge lamp

A high-intensity discharge lamp and electrode technology, which is applied to discharge lamps, gas discharge lamp parts, gas discharge lamps, etc., can solve the problems of special lamps and electrodes that are not mentioned for starting, difficult to start, and no disclosure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

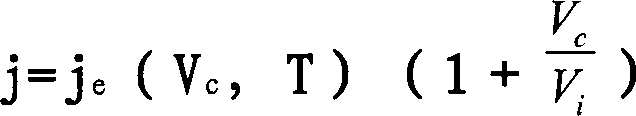

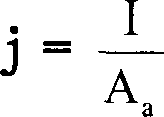

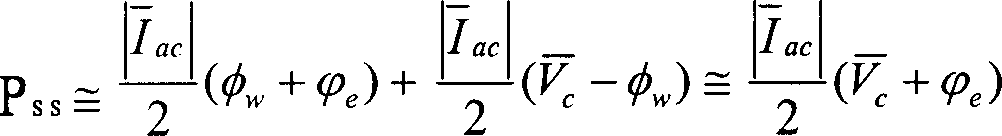

[0027] FIG. 1 shows a cross-sectional view of the arc discharge lamp 10. The high-intensity discharge lamp 10 with improved start-up and steady-state maintenance may be constituted by a light-transmissive lamp housing 12 having a wall 14 that defines a sealed volume 16. At least one electrode assembly 18 extends in a sealed form from the outside of the housing 12 through the lamp wall 14 to the sealed volume 16 which is to be exposed at the inner end of the electrode assembly. Also sealed in the housing volume 16 is a lamp filling 20 comprising an inert filling gas. The filling gas has a cold filling pressure p in Pascals. The electrode assembly 18 has an inner end formed by a head 22 that includes one or more glow discharge excitation notches 24, the notches 24 having a minimum spanning dimension S and a depth D of the notch.

[0028] The housing 12 may be made of a light-transmitting material, such as quartz, polycrystalline alumina (PCA), sapphire, or similar discharge lamp hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com