Contact type labyrinth seal

A labyrinth sealing and contact technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., to achieve significant effect, simple structure, suitable for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

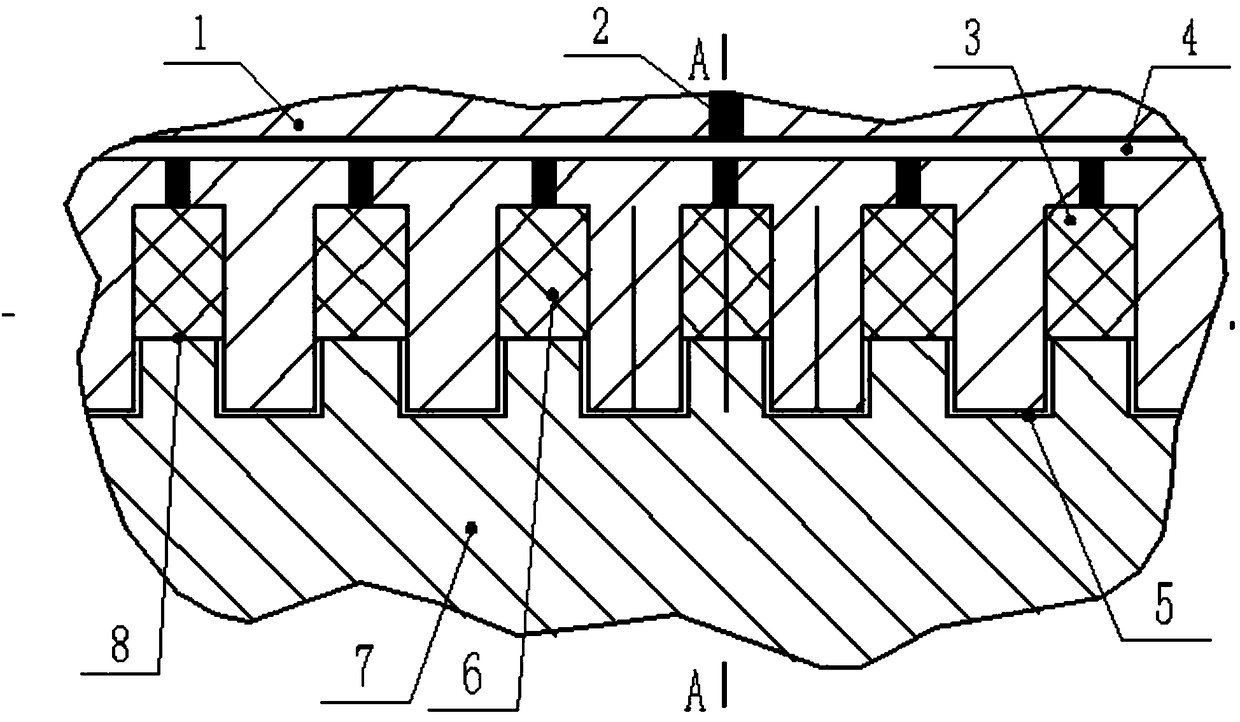

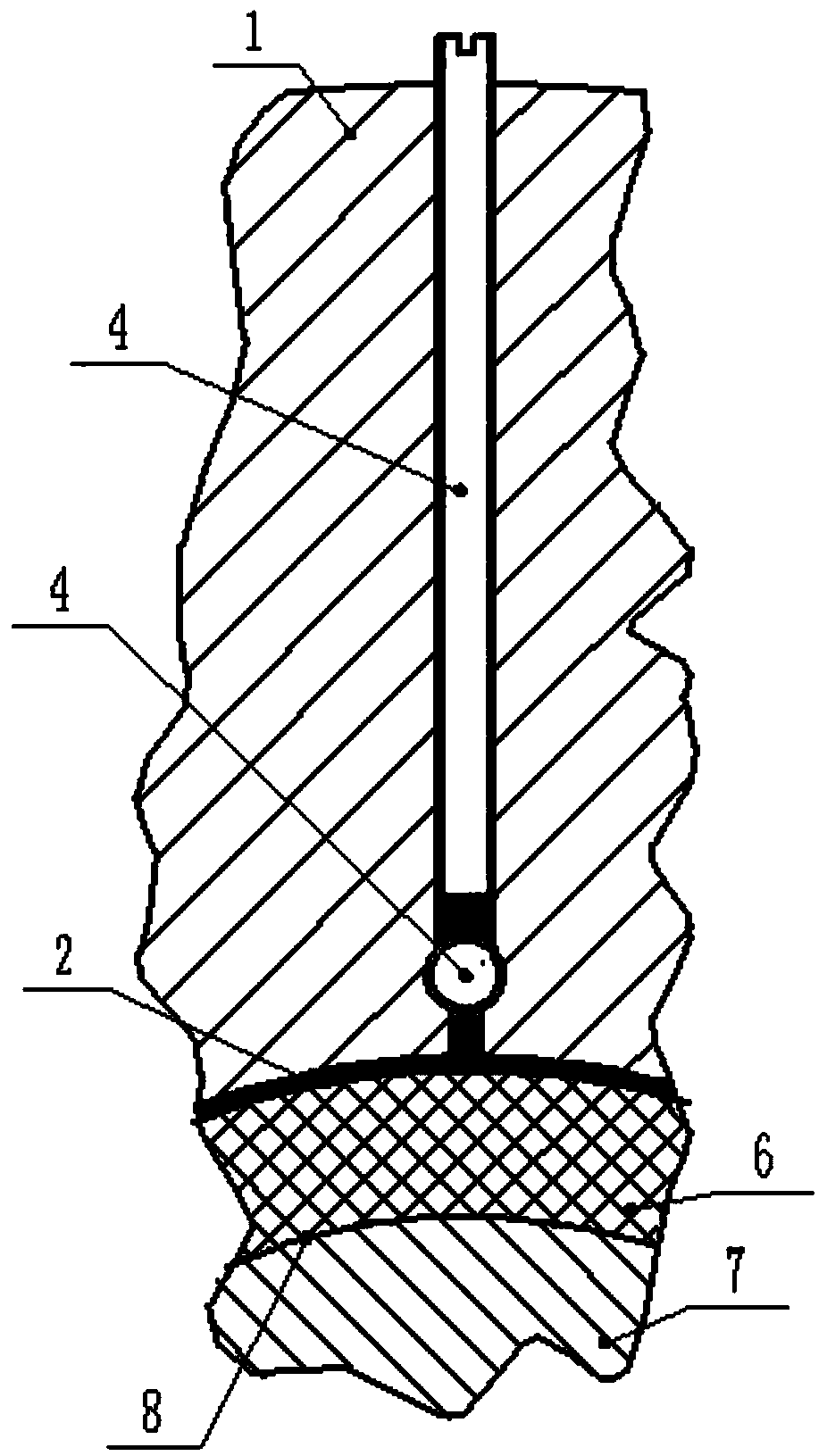

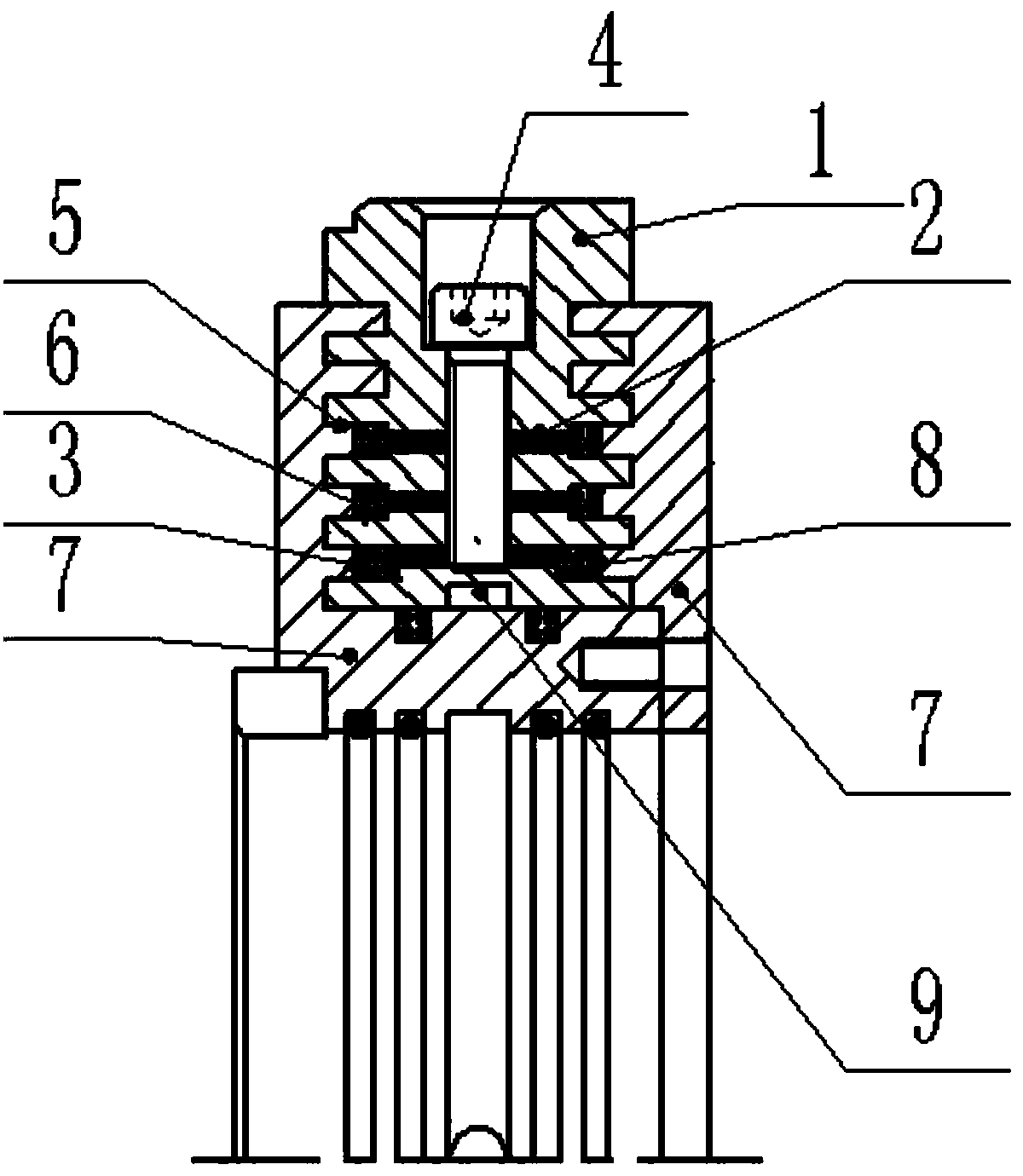

[0016] The first embodiment is a structural example of a contact labyrinth seal, such as figure 1 and figure 2 . The moving ring 7 and the static ring 1 of the axial labyrinth in this example are respectively a cylinder and a cylinder that is socketed with it and is tightly combined with two half rings. The cross-section of the shaft is rectangular, and the ring platform and the ring groove fit with each other with a gap, and the gap between the continuous fitting sections forms a labyrinth-sealed channel 5 . The ring belt at the bottom of the ring groove of the stationary ring matched with the outer edge of the ring platform of the moving ring is replaced by the elastic sealing ring 6 closely combined with the ring groove. The above is the description of the main structure of this example.

[0017] During installation, outside each ring platform o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com