High-temperature nitriding ultrafine deformation control method of thin-walled dual-shell titanium alloy bushing

A high-temperature nitriding and deformation control technology, which is applied in coating, solid-state diffusion coating, metal material coating process, etc., can solve the problems of inconsistent temperature rise inside and outside parts, deformation, low thermal conductivity of titanium alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment.

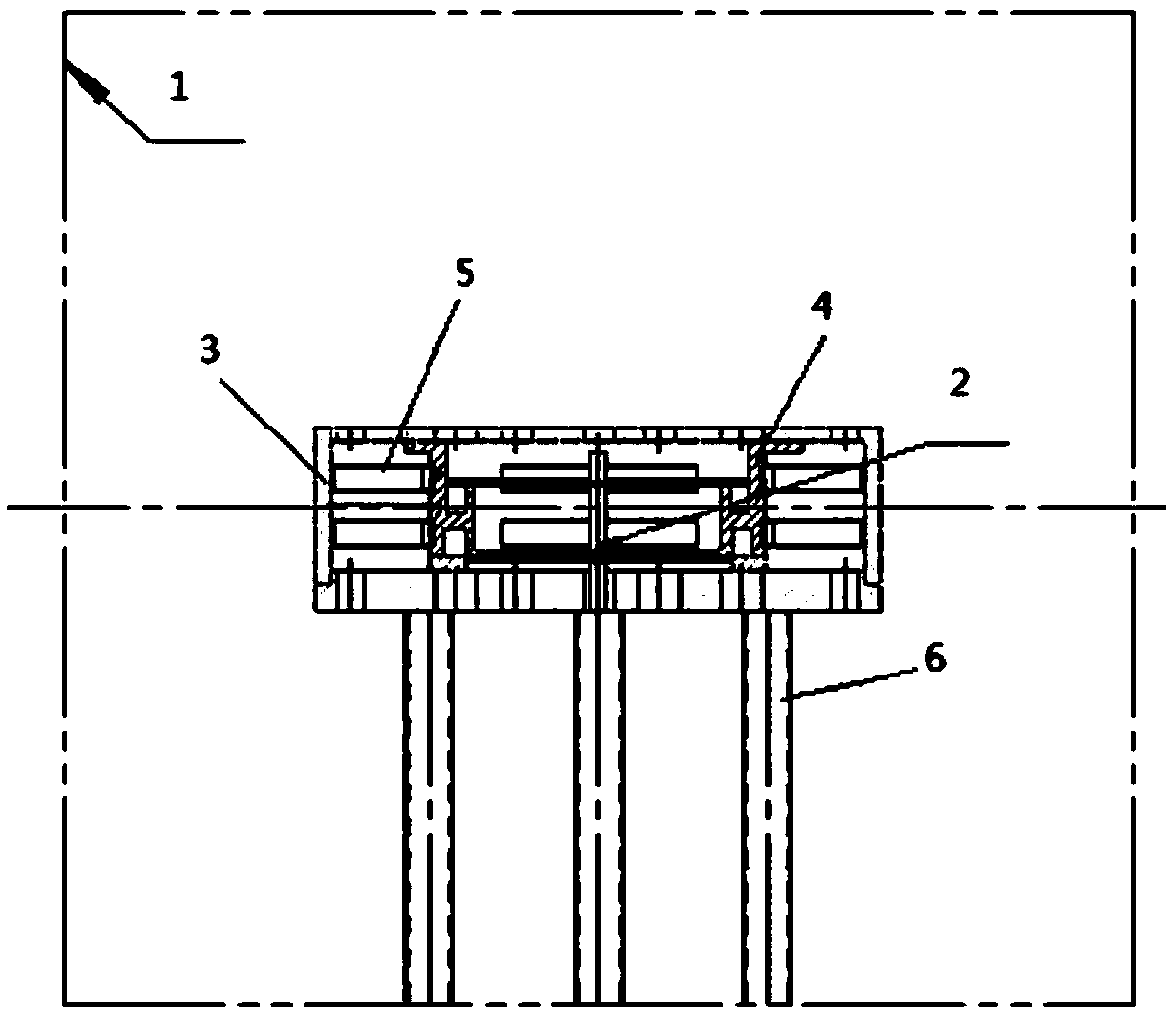

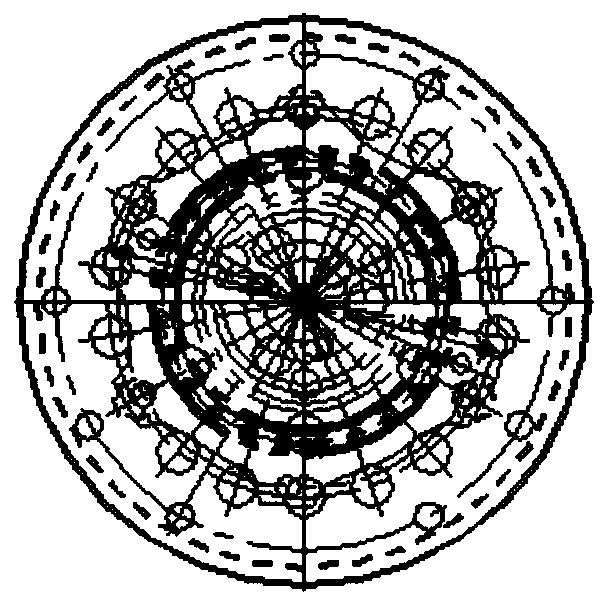

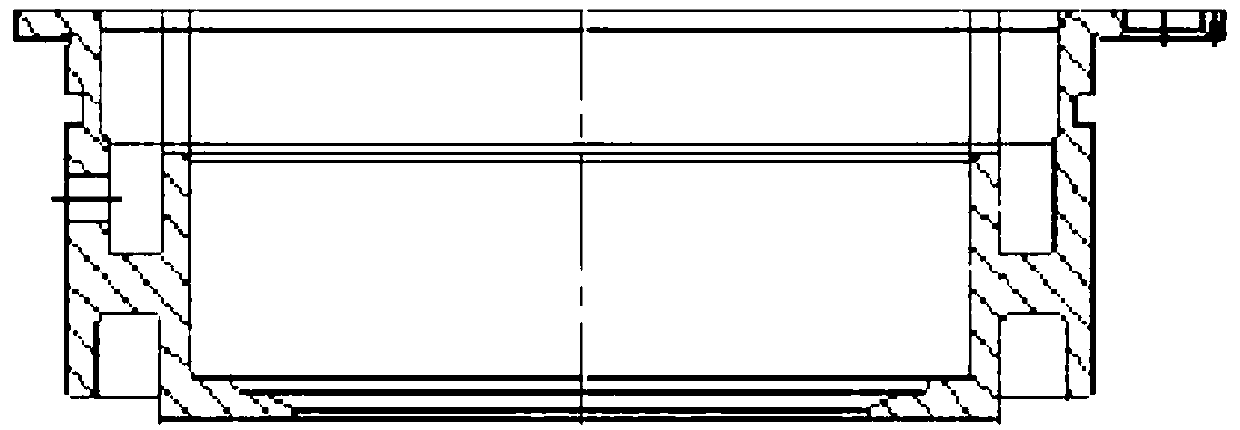

[0026] Take a thin-walled double-shell titanium alloy bearing bush as an example. The bush material is TA7. The geometric dimensions of the bearing bush are as follows: image 3 with Figure 4 As shown, the ellipse of the thin-walled double-shell titanium alloy bearing bush after ion nitriding requires ≤0.02mm and taper≤0.01mm.

[0027] Selecting special equipment for titanium alloy ion nitriding with auxiliary heat source can improve the uniformity of furnace temperature in the geometric space of the furnace, reduce furnace temperature fluctuations, and reduce the degree of deformation of parts caused by furnace temperature fluctuations.

[0028] By using 1Cr18Ni9Ti stainless steel conduit support, connected with the cathode disk, and using the TA7 material cylindrical auxiliary cathode tooling, the geometric space of the equipotential negative glow area is constructed in the ion n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com