Waterproof ability testing system of three-directional loaded shield tunnel duct piece joint seam

A shield tunnel segment and test system technology, which is applied in the field of shield tunnel segment seam waterproof ability test system, can solve the problems of simple structure and single function, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

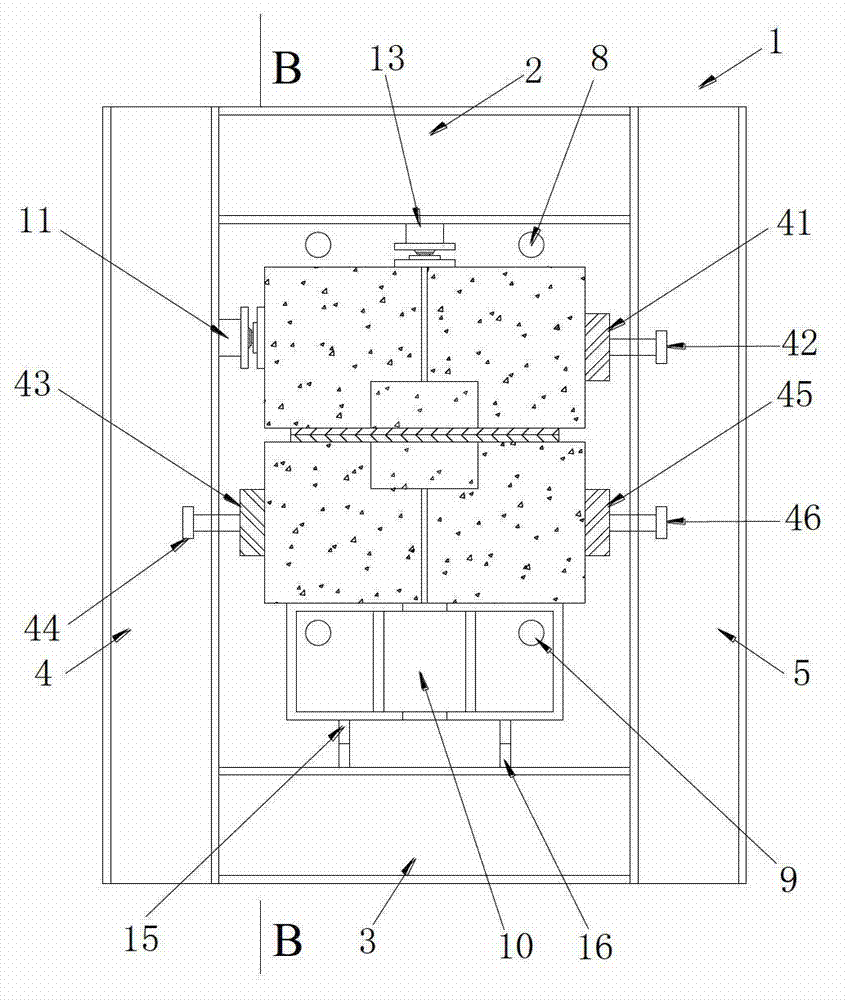

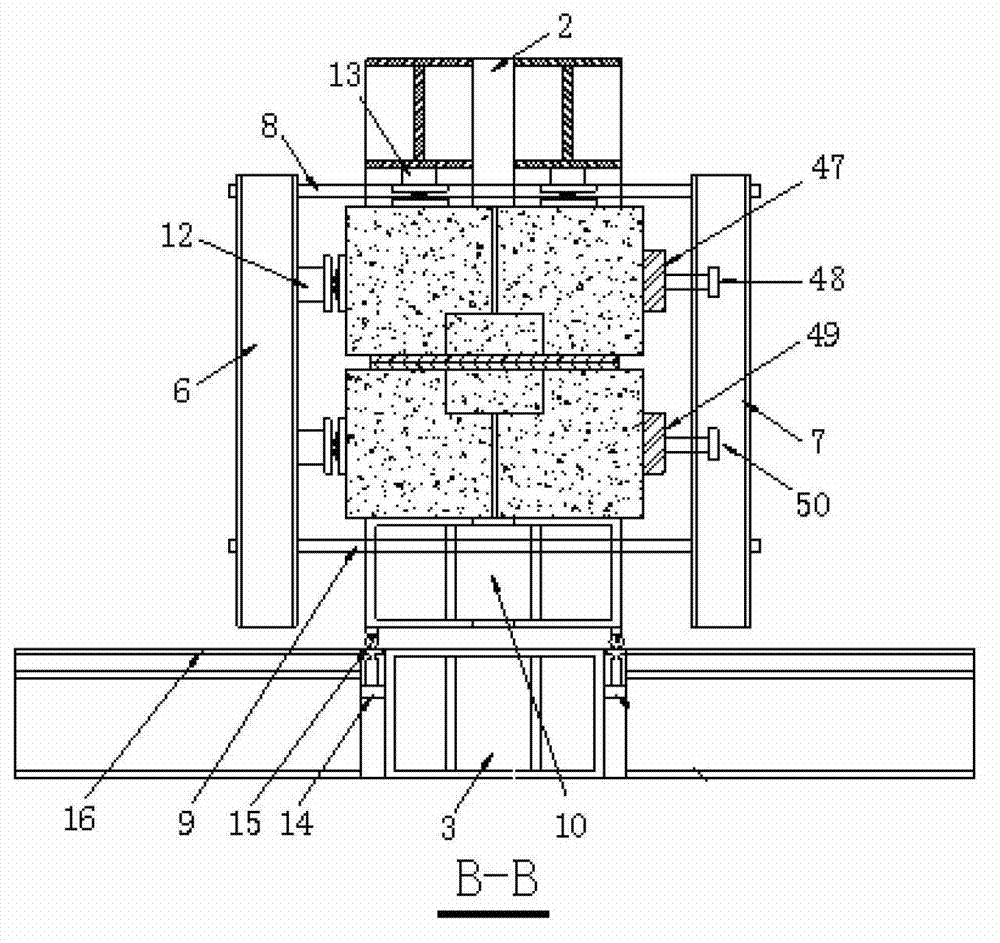

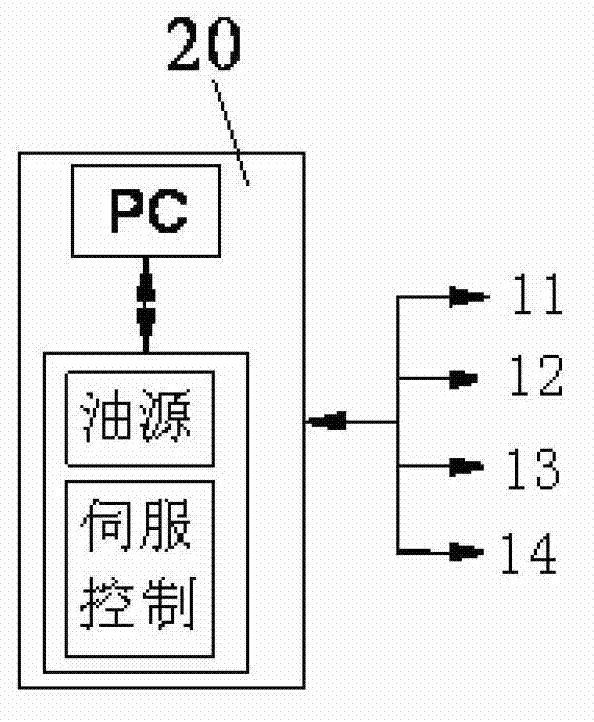

[0043] figure 1 It is a structural schematic diagram of the shield tunnel segment seam waterproof ability test system with three-way loading of the present invention; figure 2 for along figure 1 The cross-sectional view of the B-B line in the center; image 3 It is a structural schematic diagram of the load and deformation control subsystem of the shield tunnel segment seam waterproof capability test system with three-way loading of the present invention.

[0044] A shield tunnel segment seam waterproof capability test system with three-way loading, the system includes a self-balancing frame system subsystem, a load and deformation control subsystem, a specimen transport subsystem, an operation subsystem, and a data acquisition subsystem; The balance frame system subsystem and the load and deformation control subsystem are connected by bolts, the balance frame system subsystem and the specimen delivery subsystem are connected by bolts, the load and deformation control subsy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com