Welding deformation control aid of large-size stainless steel cylinder and welding deformation control method

A stainless steel cylinder, welding deformation technology, applied in welding/cutting auxiliary equipment, manufacturing tools, welding equipment, etc., can solve problems such as difficulty in ensuring no deformation, adverse effects on the performance of cylinder materials, and difficult problems, and achieve easy to master and avoid mechanical problems. Shape correction and hot shape correction process, the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

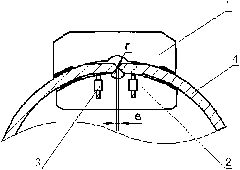

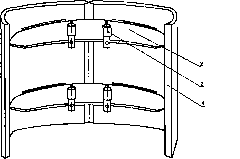

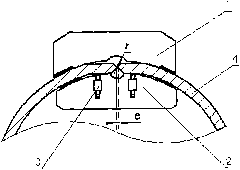

[0020] The present invention will be further described below in conjunction with the embodiments given in the accompanying drawings. An example is the welding of cylinders of nuclear power equipment.

[0021] First prepare a large-scale welding platform at the welding site, and draw the assembly reference line of the inner and outer circumference of the cylinder on the welding platform as a reference base for assembling the cylinder. Hoist the arc section of the cylinder on the platform, place it in place according to the assembly reference line drawn on the inner and outer circumference of the cylinder, measure the length and angle of the unattached line length section on both sides of the longitudinal seam of the cylinder in a free state, and determine the rigid restraint range. Prepare rigid restraint aids according to the scope of rigid restraint. The aids include inner and outer arc flat plates and top wires. The inner arc flat plate is an arc lath with a convex arc on on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com