Negative photoresist regeneration method for part of mask aligner during yellow-light process

A technology of yellow light process and components, which is applied in the field of negative photoresist regeneration of yellow light process lithography machine parts, which can solve the problems of corrosion, component aging, high production cost, etc., and achieve the effect of improving solvency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

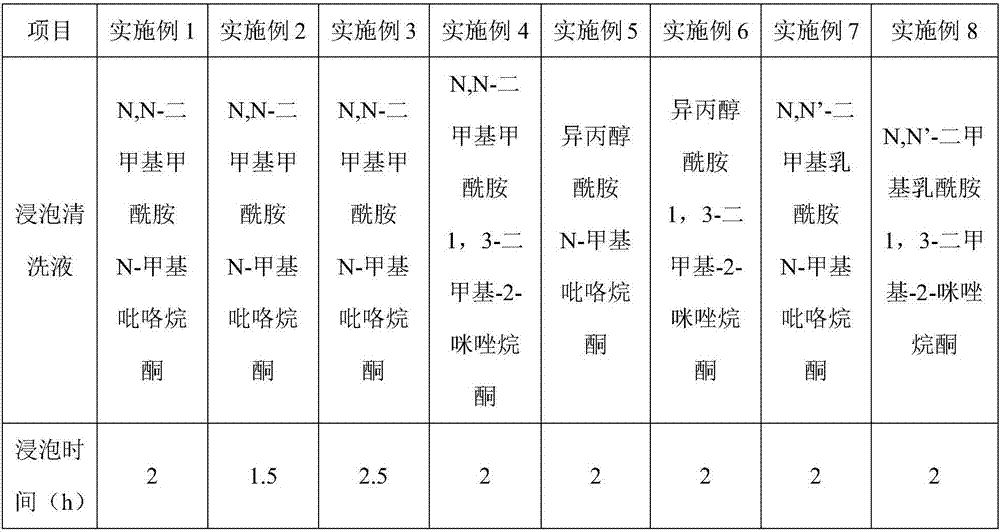

[0024] A method for regenerating the negative photoresist of a part of a yellow-light process photolithography machine described in Embodiment 1-7 of the present invention includes the following steps:

[0025] 1) Selection and preparation of the immersion cleaning solution: the selection of the immersion cleaning solution is an amide solvent and a ketone organic solvent, and the compound volume ratio of the amide solvent and the ketone organic solvent is 3:1;

[0026] 2) Soaking: Pour the immersion cleaning solution prepared in step 1) into the immersion tank, and then immerse the parts to be cleaned and regenerated into the immersion cleaning solution to dissolve most of the solidified or liquid negative photoresist;

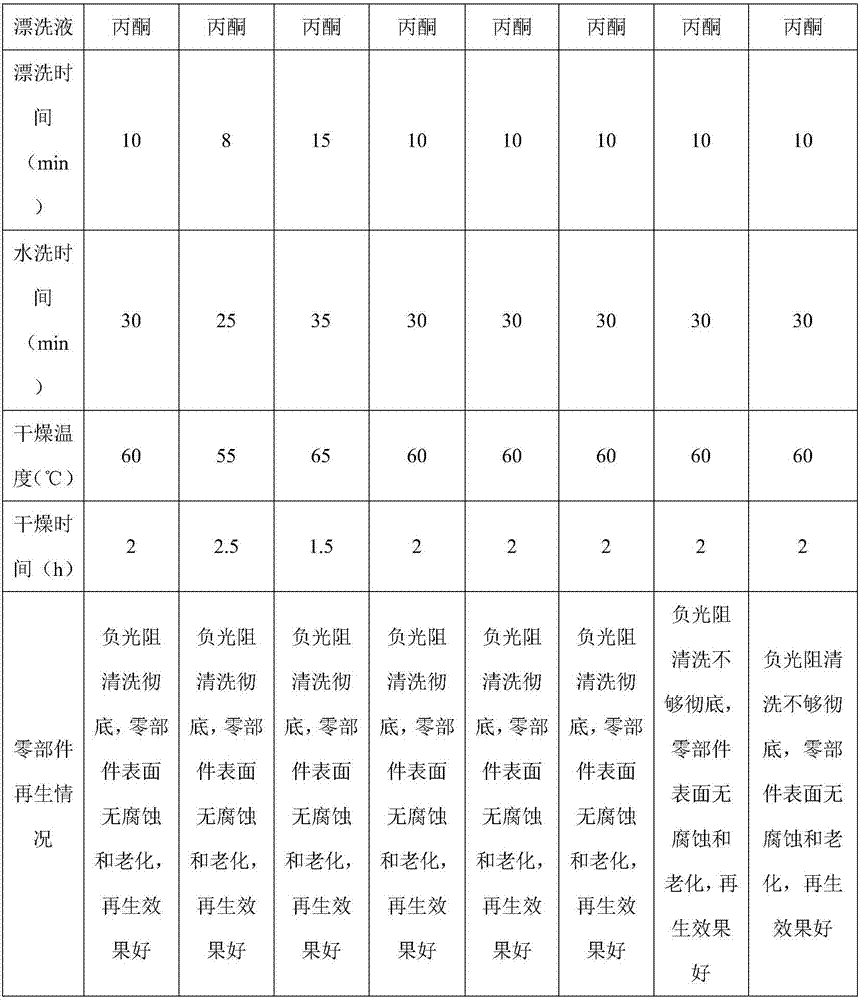

[0027] 3) Rinse: Rinse the soaked parts with acetone solvent to remove the residual negative photoresist and soaking cleaning solution on the sides and corners of the parts, so that the parts can be recycled and used;

[0028] 4) Washing: wash the parts after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com