Device and method for preparing graphene film on basis of plasma

A graphene thin film and plasma technology, applied in the field of energy storage materials, can solve the problems that hinder the large-scale preparation and application of high-quality nanomaterials, destroy the graphene sheet structure, and the plasma electron energy is large, and meet the thermal stability requirements of the equipment Low, reduce pollution and human health hazards, mild and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 2) Preparation of graphene oxide film: ultrasonically disperse the graphene oxide prepared in step 1) in deionized water to obtain a uniformly dispersed graphene oxide solution, which is filtered through a microporous membrane with a pore size of 0.22 microns and dried. Tear off the graphene oxide film from the microporous membrane for subsequent use;

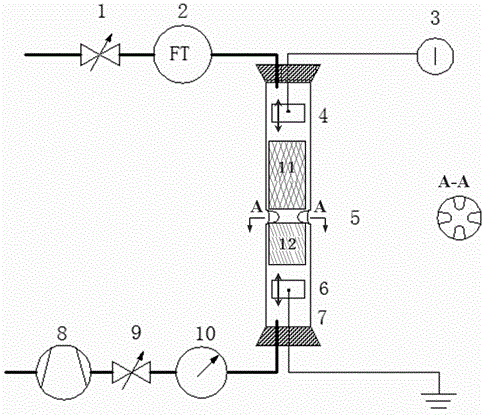

[0036]3) Put the graphene oxide film prepared in step 2) on the sample support frame 5, turn on the vacuum pump 8 and the gas regulating valve 1, pass inert gas into the quartz tube 7, and adjust the flow rate of the inert gas with the mass flow meter 2 to 7-10 ml / min, rotate the vacuum regulating valve 9, and adjust the air pressure in the quartz tube 7 to 250-320 millitorr;

[0037] 4) Keep the air pressure and gas flow in the quartz tube 7 constant, turn on the high-voltage negative power supply 3, adjust the voltage to 7-10 kV, and form a stable glow discharge plasma between the cathode electrode 4 and the anode elec...

Embodiment 1

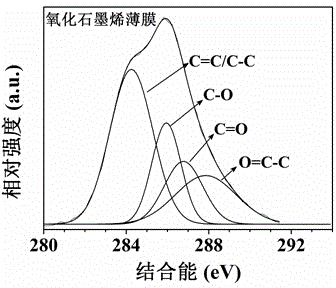

[0043] 1. Modified Hummers oxidation method to prepare graphene oxide: natural flaky graphite and concentrated sulfuric acid (mass concentration 98%) were stirred evenly at room temperature, wherein the mixing ratio of concentrated sulfuric acid and natural flaky graphite was 25 mg: 1 gram, and the mixture was placed in an ice bath After dropping to 0 oC, slowly add potassium permanganate to it and mix evenly with magnetic stirring, wherein the quality of potassium permanganate is 3.5 times that of natural flake graphite. Cool down, then add deionized water and hydrogen peroxide in sequence, wherein the ratio of deionized water to natural flake graphite is 100 ml: 1 g, and the ratio of peroxidized to natural flake graphite is 8 ml: 1 g, the mixed solution Repeated cleaning treatment by high-speed centrifugation, placed in the air, and dried at room temperature to obtain graphene oxide.

[0044] 2. Preparation of graphene oxide film: ultrasonically disperse the graphene oxide...

Embodiment 2

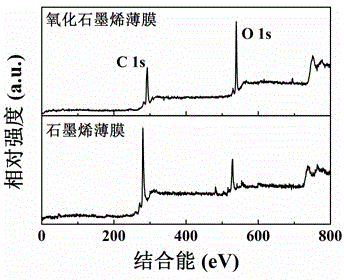

[0052] Repeat Example 1, the only changes in the working conditions are: the distance between the cathode and anode plates is 80 mm, the distance between the cathode plate and the sample is 60 mm, and the distance between the anode plate and the sample is 20 mm, that is, the distance ratio between the cathode electrode, the anode electrode and the sample support frame 3, the inert gas is helium, the helium gas flow rate is 10 ml / min, the DC high voltage negative power supply voltage is 7 kV, and the reaction lasts for 1 minute. The carbon-oxygen atomic ratio of the graphene film obtained above is 6.5, and the peak intensity ratio of the D peak and the G peak is 1.06.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com