PLD (pulsed laser deposition) system provided with hollow cathode plasma and preparation method of thin film

A plasma and hollow cathode technology, applied in the field of thin film transistors, can solve the problems that the performance of ITO thin films cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

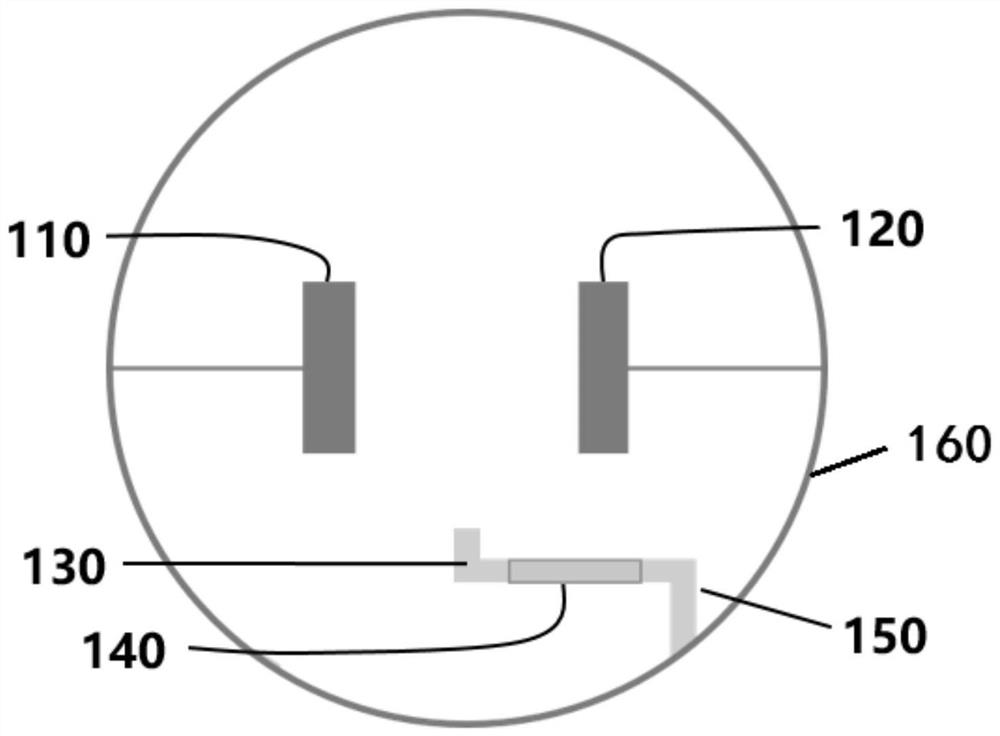

[0030] The invention also discloses a method for preparing an amorphous ITO thin film of a PLD system with a hollow cathode plasma, the preparation method comprising the following steps:

[0031] Step 1, providing and installing a deposition substrate 110;

[0032] Step 2, start the pulsed laser deposition to prepare the amorphous ITO thin film. During the deposition process, the pulsed laser power is 400mJ, the laser frequency is 1Hz, and the distance between the target and the substrate is 70mm. The thickness of the ITO film is about 20nm, the growth rate of the ITO film is 0.8-1nm / pulse, and the amorphous ITO film is deposited in a single-point manner.

[0033] During the deposition process, the hollow cathode plasma discharge device is turned on, and the background pressure is less than 5×10 -5 Pa, oxygen is used as the working gas, the gas pressure is 3.5-4Pa, the ionization voltage and current are less than 50mA, and the ionization power is less than 60W.

Embodiment 1

[0036] The present embodiment provides a kind of method utilizing hollow cathode discharge plasma assisted PLD to prepare ITO film, and it comprises the following steps:

[0037] (1) Provide deposition substrates (including but not limited to Si / SiO2);

[0038] (2) Utilize hollow cathode discharge plasma-assisted PLD to prepare ITO film on described substrate;

[0039] In step (2), the ITO film is prepared by pulsed laser deposition, the thickness of the ITO film is about 20 nm, and the growth rate of the ITO film is 0.8-1 nm / pulse.

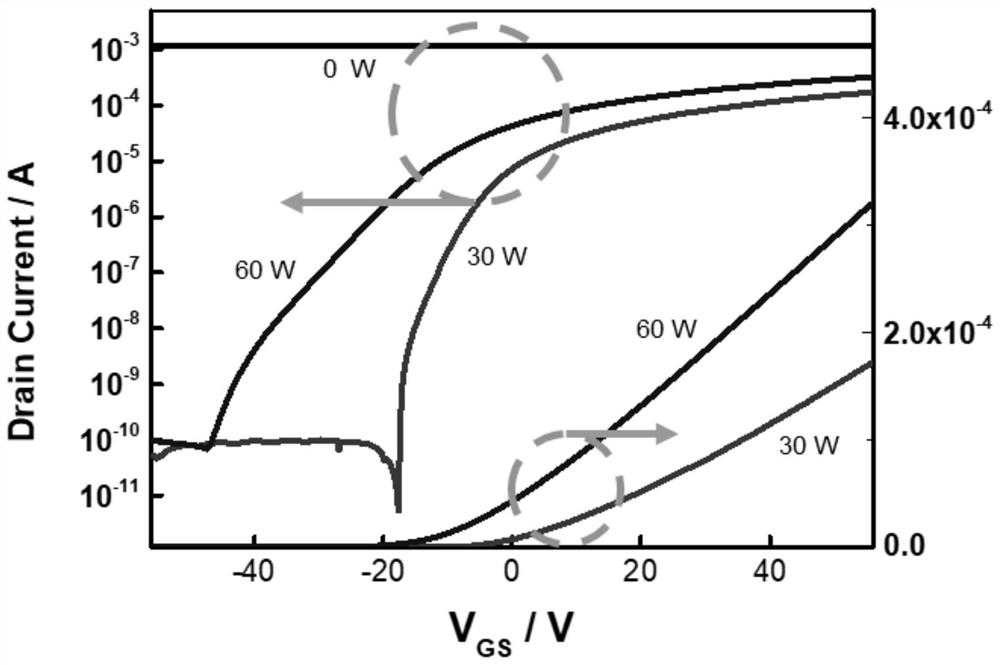

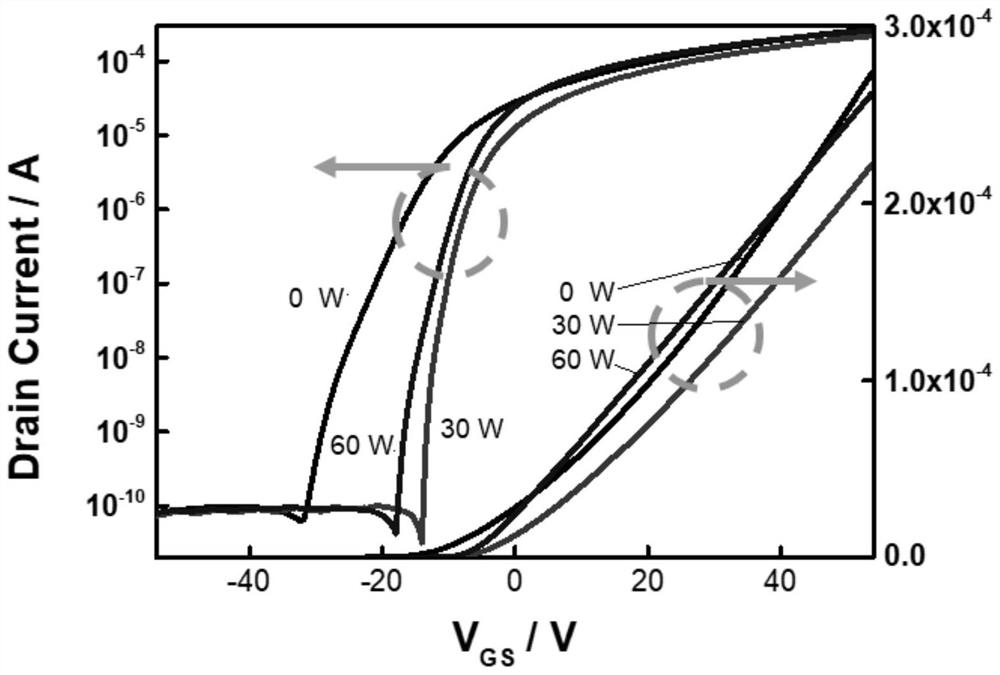

[0040] In step (2), the hollow cathode discharge plasma assisted PLD is used to prepare the ITO film on the substrate, the ionization voltage is 1.5kV, the ionization current is 20mA, and the vacuum degree is lower than "5×"〖"10"〗^ "-5"Pa, through O 2 As the working gas, the gas pressure is 3.5Pa, the laser power is 400mJ, and the substrate temperature is room temperature.

Embodiment 2

[0042]The difference between this embodiment and Embodiment 1 is that the ionization voltage of the hollow cathode discharge plasma is 2.0 kV, and the ionization current is 30 mA. Other operating steps and parameters are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com