Preparation for copper-indium-galliun-selenium-sulfur or copper-indium-galliun-selenium or copper-indium-galliun-sulfur film solar cell absorption layer

A copper indium gallium selenide sulfur, solar cell technology, applied in coatings, circuits, electrical components and other directions, can solve the problems of poor safety, difficult transportation and storage, high price, etc., to increase the scope of application and avoid highly toxic gases , the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

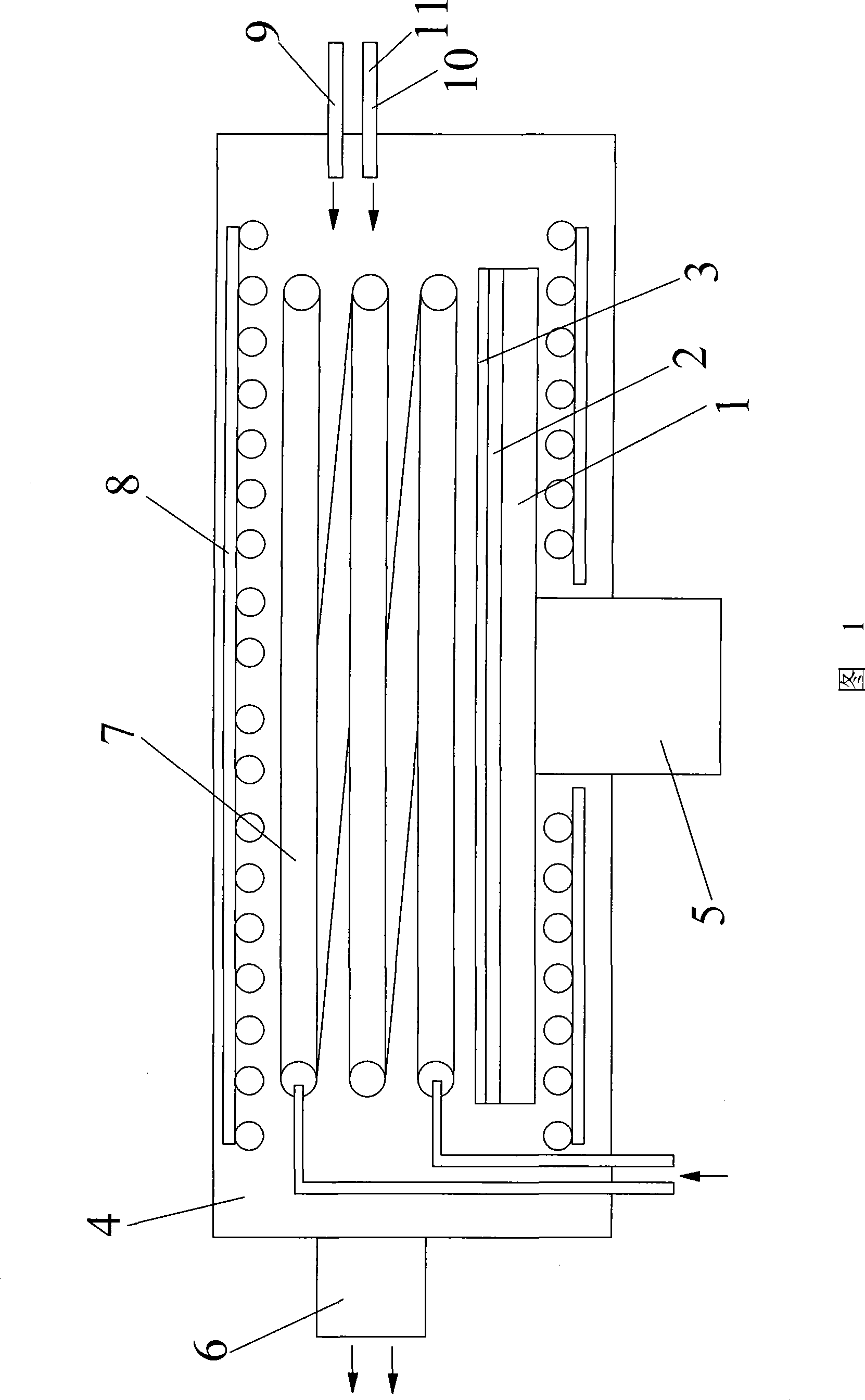

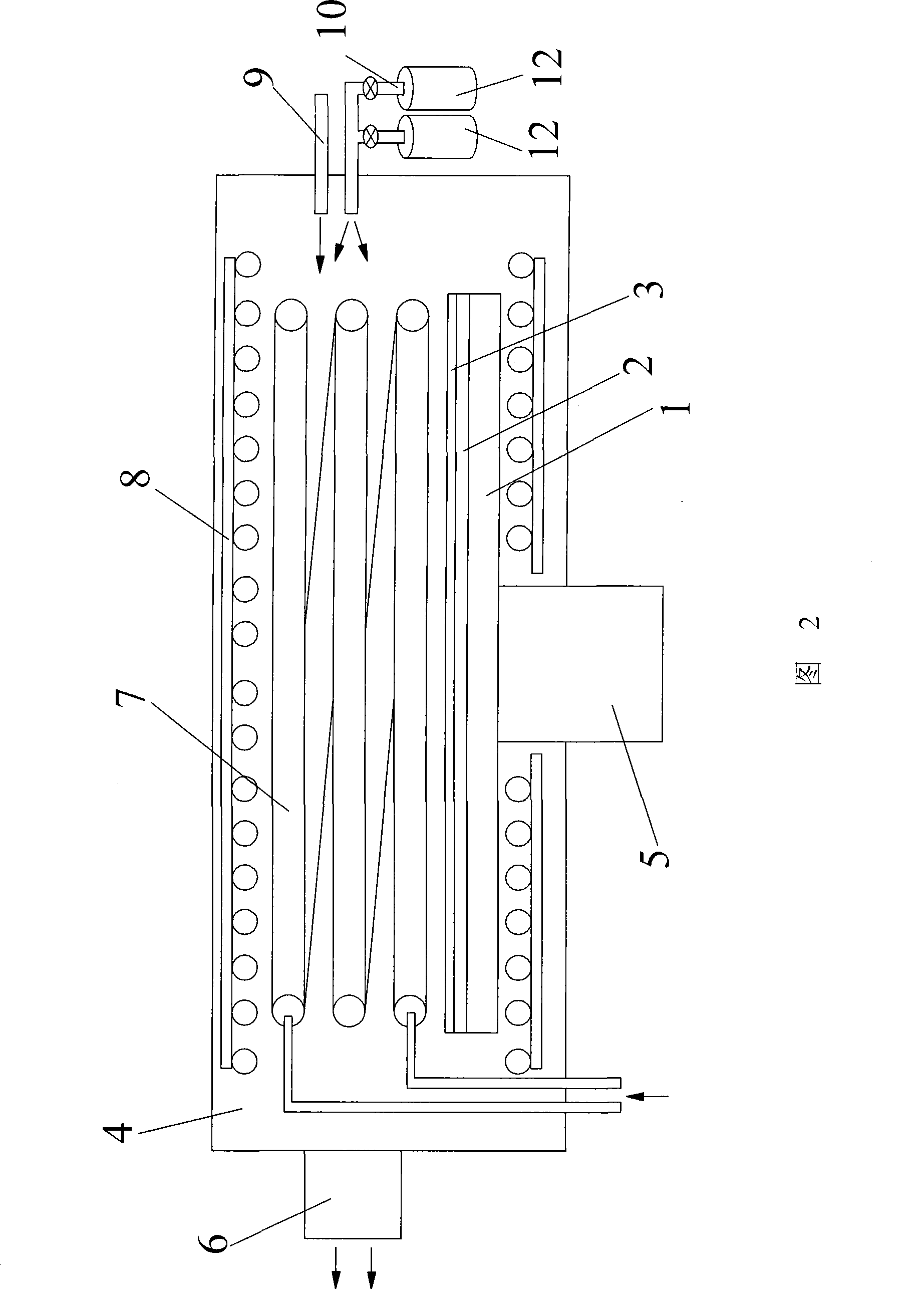

[0034] A method for preparing an absorber layer of a copper indium gallium selenide thin film solar cell, comprising the following steps:

[0035] 1) Prepare the underlying conductive film: on the substrate 1, use mask evaporation or sputtering to form the underlying metal conductive film 2;

[0036] 2) Preparing the metal precursor film 3 of the thin-film battery: plating the metal precursor film 3 of copper, indium, and gallium on the underlying conductive film 2 by magnetron sputtering or vacuum evaporation;

[0037] 3) Selenization reaction: place the module to be processed in the reaction vessel 4, then evacuate the reaction vessel 4 into a vacuum state, and fill the reaction vessel 4 with a protective gas that does not react with copper, indium, and gallium to achieve a certain vacuum degree, for example: 1×10 -1 After the vacuum degree of Pa, carry out heating and plasma discharge in the reaction vessel, the heating can choose a value between 200~600 ℃ (for example, wh...

specific Embodiment 2

[0041] A method for preparing an absorber layer of a copper indium gallium sulfide thin film solar cell: using organometallic sulfur to replace the organometallic selenium in the first embodiment, and the other being the same as the first embodiment, to obtain an absorber layer of a copper indium gallium sulfide thin film solar cell.

specific Embodiment 3

[0042] A preparation method for the absorbing layer of a copper indium gallium selenide sulfur thin film solar cell: use organic metal sulfur and organic metal selenium to replace the organic metal selenium in the first embodiment, and the other is the same as the first embodiment to obtain a copper indium gallium selenide sulfur thin film solar cell battery absorber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com