Method for preparing GIGS solar cell by applying one-step sputtering method

A technology of copper indium gallium selenide and solar cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high cost of selenization process, difficult control of Ga content and distribution, high technical difficulty of CIGS thin film solar cells, and achieve operational Simple and controllable steps, high conversion efficiency and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

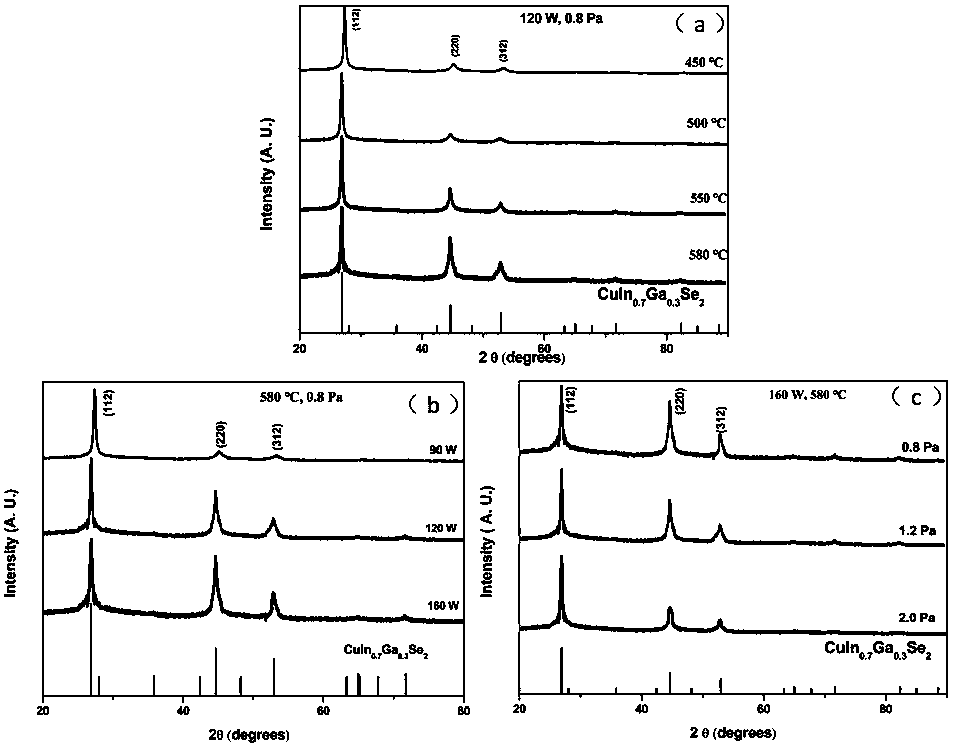

[0030] 1. Preparation of CIGS absorber layer by one-step sputtering method

[0031] Firstly, the soda-lime glass was ultrasonically cleaned with toluene, acetone, and deionized water for 10 minutes in turn. The Mo back electrode was deposited on cleaned soda-lime glass by DC sputtering using a high-purity Mo target. The selenium-rich CIGS target was deposited with different radio frequency sputtering parameters to obtain the CIGS absorbing layer, and the crystal structure of the film in the range of 20° to 90° was detected by using a DX-2000 X-ray powder diffractometer. attached figure 1 It is the XRD pattern of chalcopyrite phase CIGS thin film. The peaks of 2θ values at 26.9°, 44.6° and 52.9° correspond to Cu(In 0.7 Ga 0.3 ) Se 2 (112), (220) and (312) crystal planes of the chalcopyrite phase (JCPDS-#351102).

[0032] This result indicates that the CIGS film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com