Method for measuring content of selenium in molybdenum and molybdenum product

A product and content technology, applied in the field of determination of selenium content in molybdenum and molybdenum products, can solve the problems of difficulty in forming and cannot use molybdenum and molybdenum products to measure selenium content, and achieve the effects of high efficiency, simple operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

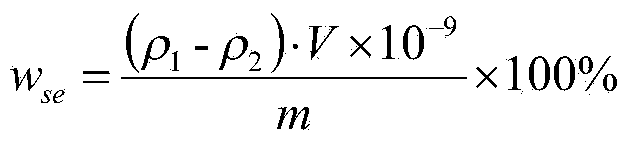

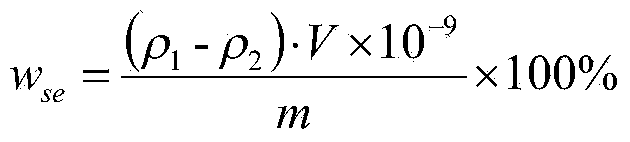

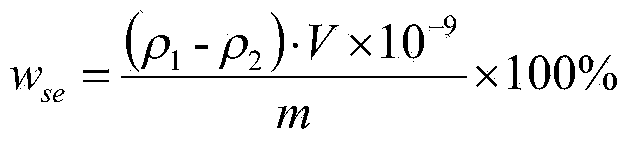

Image

Examples

Embodiment 1

[0036] The method for measuring selenium content in molybdenum and molybdenum products of the present invention comprises the steps:

[0037] The first step, sampling

[0038] Take the molybdenum bar to be determined. After preliminary determination, the mass fraction of selenium in the molybdenum bar is between 0.0001% and 0.0010%. The molybdenum bar is crushed, and then sieved with a standard sieve with a mesh diameter of 0.75mm Points, get samples;

[0039] The second step, prepare sample solution and sample blank solution

[0040] Take two beakers with a capacity of 150mL, put 0.5g of the sample prepared in the first step into one of the beakers, and add water to wet the sample, then add 15mL of hydrochloric acid with a concentration of 12.40mol / L to the two beakers Solution A and 5mL nitric acid solution with a concentration of 15.32mol / L, cover with a watch glass, heat two beakers to 150°C until the sample is completely dissolved, then add 5mL citric acid with a concen...

Embodiment 2

[0053] The method for measuring selenium content in molybdenum and molybdenum products of the present invention comprises the steps:

[0054] The first step, sampling

[0055] Take the molybdenum powder to be determined. After preliminary determination, the mass fraction of selenium in the molybdenum powder is between 0.0010% and 0.0020%. The molybdenum powder is divided three times according to the quartering method to obtain a sample;

[0056] The second step, prepare sample solution and sample blank solution

[0057] Take two beakers with a capacity of 150mL, put 0.10g of the sample prepared in the first step into one of the beakers, and add water to wet the sample, then add 15mL of hydrochloric acid with a concentration of 11.65mol / L to the two beakers Solution A and 5mL nitric acid solution with a concentration of 14.32mol / L, cover with a watch glass, heat two beakers to 180°C until the sample is completely dissolved, then add 5mL citric acid with a concentration of 800g...

Embodiment 3

[0070] The method for measuring selenium content in molybdenum and molybdenum products of the present invention comprises the steps:

[0071] The first step, sampling

[0072] Take the molybdenum powder to be determined. After preliminary determination, the mass fraction of selenium in the molybdenum powder is between 0.0030% and 0.0050%. The molybdenum powder is divided three times according to the quartering method to obtain a sample;

[0073] The second step, prepare sample solution and sample blank solution

[0074] Take two beakers with a capacity of 150mL, put 0.10g of the sample prepared in the first step into one of the beakers, and add water to wet the sample, and then add 15mL of hydrochloric acid with a concentration of 12mol / L to the two beakers Solution A and 5mL nitric acid solution with a concentration of 15mol / L, cover with a watch glass, heat two beakers to 170°C until the sample is completely dissolved, then add 5mL citric acid solution with a concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com