Three-dimensional nickel cobaltate@cobalt selenide (II) nanoneedle array composite material as well as preparation method and application thereof

A composite material and nanoneedle technology, which is applied in the field of three-dimensional nickel cobaltate@cobalt selenide nanoneedle array composite material and its preparation, can solve the problem of reducing the available surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

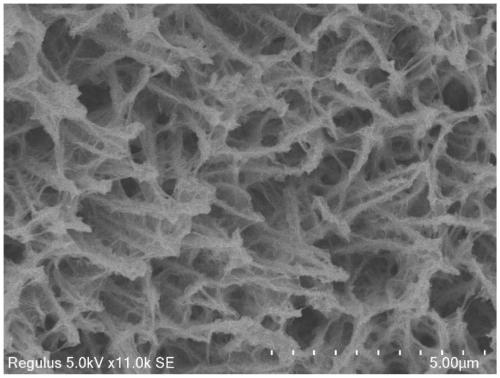

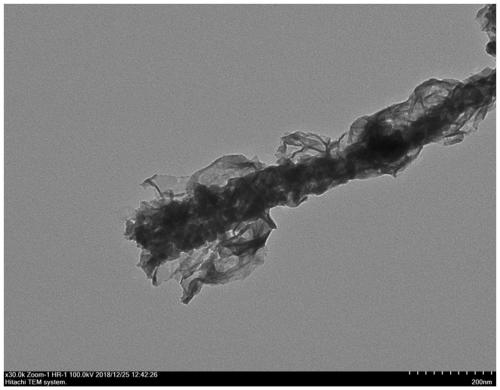

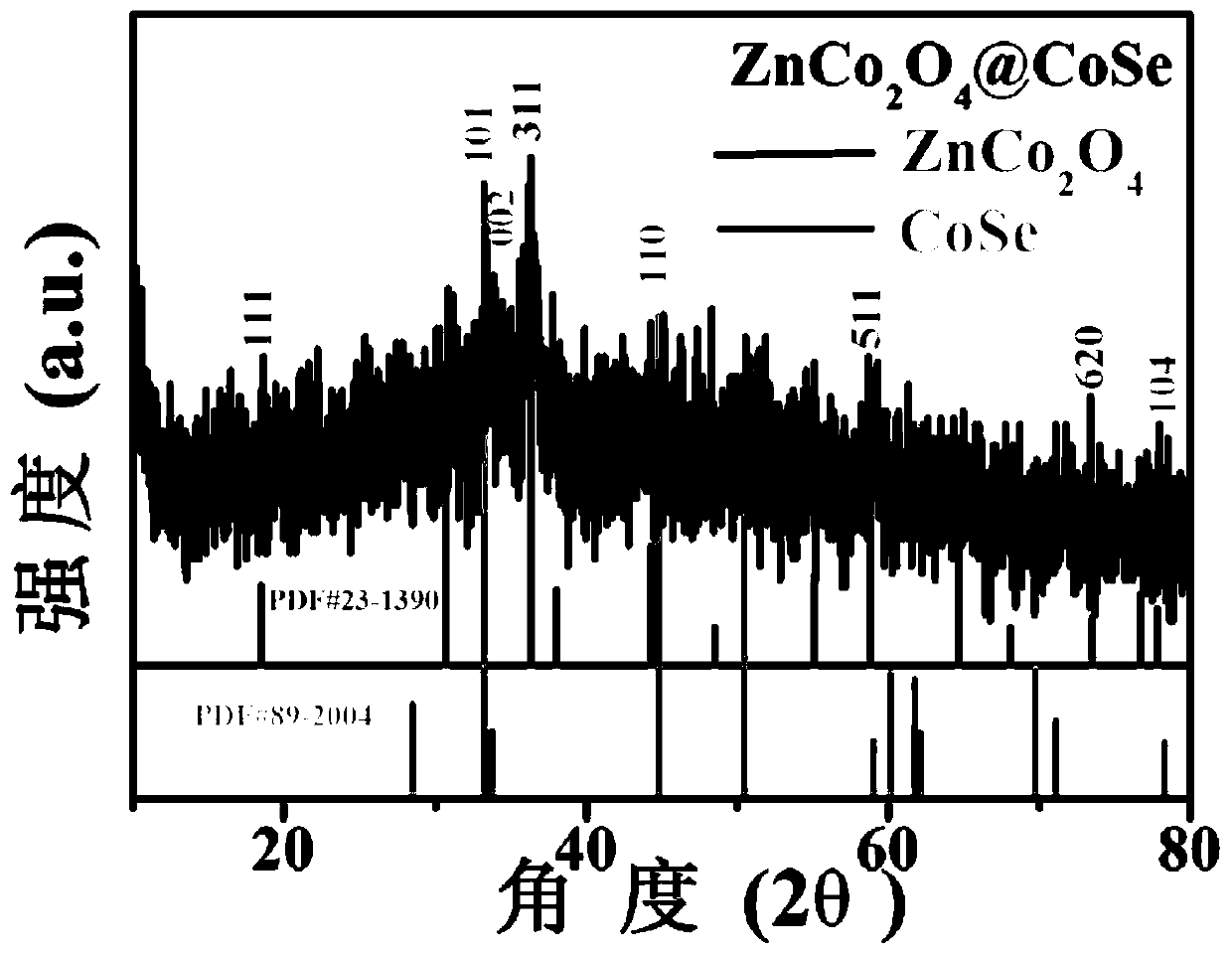

[0020] The present invention also provides the above-mentioned three-dimensional ZnCo 2 o 4 The preparation method of @CoSe nanoneedle array composite material, including: ZnCo 2 o 4 Hydrothermal reaction of nanoneedle arrays, sodium selenide and cobalt derived from water to produce three-dimensional ZnCo 2 o 4 @CoSe nanoneedle array composites.

[0021] In the above preparation method, the amount of each material can be selected in a wide range, but in order to further improve the prepared three-dimensional ZnCo 2 o 4 Electrocatalytic activity and cycle stability of @CoSe nanoneedle array composites, preferably, ZnCo 2 o 4 The dosage ratio of the nanoneedle array, sodium selenium hydride and cobalt acetate hexahydrate is 0.02g-0.07g:0.5-2.5mmol:0.5-2.5mmol.

[0022] In the above preparation method, the amount of water can be selected in a wide range, but in order to improve the reaction rate and yield, preferably, ZnCo 2 o 4 The dosage ratio of the nanoneedle array ...

Embodiment 1

[0033] 1) Dissolve 1mmol of cobalt nitrate hexahydrate, 0.5mmol of zinc nitrate hexahydrate, 1mmol of ammonium fluoride, and 2.5mmol of urea in 35ml of deionized water. After magnetic stirring for 30min, transfer the mixed solution into a 50ml reaction kettle, and then add Cleaned nickel foam (the size of one side is 2cm×3cm). Put the reaction kettle into a thermostat at 120°C, and react for 5 hours. After the reaction, wash and dry to obtain ZnCo 2 o 4 Nanoneedle array precursor; the ZnCo 2 o 4 The nanoneedle array precursor (containing nickel foam) was calcined at 400 °C for 2 h in an air atmosphere to obtain ZnCo 2 o 4 nanoneedle arrays;

[0034] 2) Add 1mmol of nickel acetate tetrahydrate, 1mmol of sodium selenium hydride and 30ml of water into a 50ml reaction kettle, and then add the ZnCo synthesized above to the kettle. 2 o 4 Nanoneedle array (containing nickel foam), sealed, put the reaction kettle into a constant temperature drying oven at 180°C for 0.5h, wash ...

Embodiment 2

[0036] 1) Dissolve 5mmol cobalt nitrate hexahydrate, 2.5mmol zinc nitrate hexahydrate, 5mmol ammonium fluoride, and 12.5mmol urea in 35ml deionized water. After magnetic stirring for 30min, transfer the mixed solution into a 50ml reaction kettle, and then add Cleaned nickel foam (the size of one side is 2×3cm). Put the reaction kettle into a thermostat at 120°C, and react for 5 hours. After the reaction, wash and dry to obtain ZnCo 2 o 4 Nanoneedle array precursor; the ZnCo 2 o 4 The nanoneedle array precursor (containing nickel foam) was calcined at 400 °C for 2 h in an air atmosphere to obtain ZnCo 2 o 4 nanoneedle arrays;

[0037] 2) Add 1mmol of nickel acetate tetrahydrate, 1mmol of sodium selenium hydride and 30ml of water into a 50ml reaction kettle, and then add the ZnCo synthesized above to the kettle. 2 o 4 Nanoneedle array (containing nickel foam), sealed, put the reaction kettle into a constant temperature drying oven at 180°C for 0.5h, wash after the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com