Growth method of zinc selenide

A growth method, zinc selenide technology, applied in the field of infrared materials, can solve problems such as product cracking, achieve the effects of eliminating stress, reducing production costs, and increasing growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

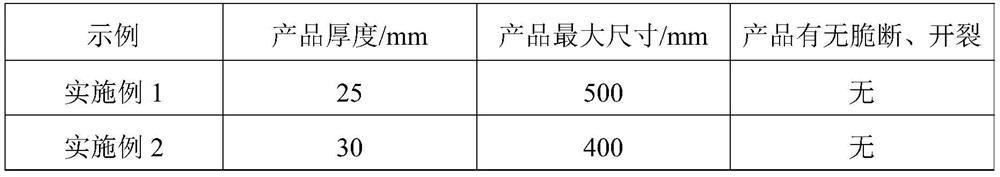

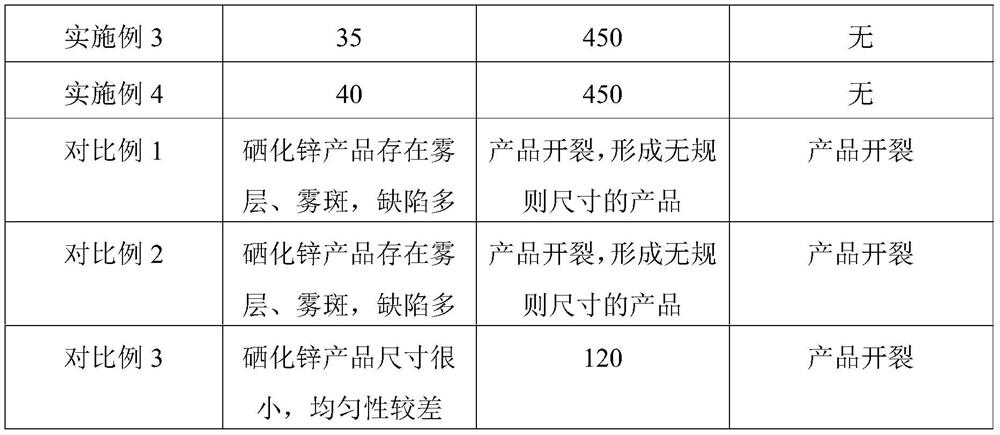

Examples

Embodiment 1

[0043] In the chemical vapor deposition furnace, a deposition chamber with a length of 600mm, a width of 300mm, and a height of 1100mm was used. Zinc ingots with a purity of 99.999% were loaded into the crucible, vacuumed, and the vacuum degree was 3000Pa, and leak detection was performed. After passing the test, start the temperature program. The heating rate of the crucible is 0.3°C / min, and the heating rate of the deposition chamber is 0.5°C / min. The temperature of the crucible is raised to 650°C, and the temperature of the deposition chamber is raised to 700°C. Then respectively in the crucible and the deposition chamber, the argon flow that passes into the crucible is 30L / min, and the evaporation rate of zinc vapor is 5L / min; the hydrogen selenide flow that passes into the deposition chamber is 5.5L / min , the flow rate of argon mixed with hydrogen selenide into the deposition chamber was 55 L / min, and the deposition rate was controlled at 80 μm / h to deposit zinc selenide. ...

Embodiment 2

[0045]In the chemical vapor deposition furnace, a deposition chamber with a length of 500 mm, a width of 400 mm, and a height of 1200 mm was used. Zinc ingots with a purity of 99.999% were loaded into the crucible, vacuumed, and the vacuum degree was 5800 Pa. Leak detection. After passing the test, start the temperature program. The heating rate of the crucible is 0.5°C / min, the heating rate of the deposition chamber is 0.8°C / min, the temperature of the crucible is raised to 680°C, and the temperature of the deposition chamber is raised to 750°C. Then respectively in the crucible and the deposition chamber, the argon flow that passes into the crucible is 50L / min, and the evaporation rate of zinc vapor is 7L / min; the flow of hydrogen selenide that passes into the deposition chamber is 9L / min The flow rate of argon gas mixed with hydrogen selenide into the deposition chamber is 100 L / min, and the deposition rate is controlled at 110 μm / h to deposit zinc selenide. After the depos...

Embodiment 3

[0047] In the chemical vapor deposition furnace, a deposition chamber with a length of 650 mm, a width of 250 mm, and a height of 800 mm was used. Zinc ingots with a purity of 99.999% were loaded into the crucible, vacuumed, and the vacuum was 10,000 Pa. Leak detection. After passing the test, start the temperature program. The heating rate of the crucible is 0.8°C / min, and the heating rate of the deposition chamber is 1°C / min. The temperature of the crucible is raised to 700°C, and the temperature of the deposition chamber is raised to 800°C. Then respectively in the crucible and the deposition chamber, the argon flow that passes into the crucible is 80L / min, and the evaporation rate of zinc vapor is 8L / min; the hydrogen selenide flow that passes into the deposition chamber is 10L / min, The flow rate of argon mixed with hydrogen selenide into the deposition chamber is 150 L / min, and the deposition rate is controlled at 150 μm / h to deposit zinc selenide. After the deposition is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com