Near-infrared copper-indium-selenium quantum dot and preparation method thereof

A copper indium selenide and near-infrared technology, which is applied in the field of nanomaterials, can solve the problems of unfavorable in vivo imaging research, limited adjustable wavelength, long reaction time, etc., and achieves the effects of simple method, short reaction time and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

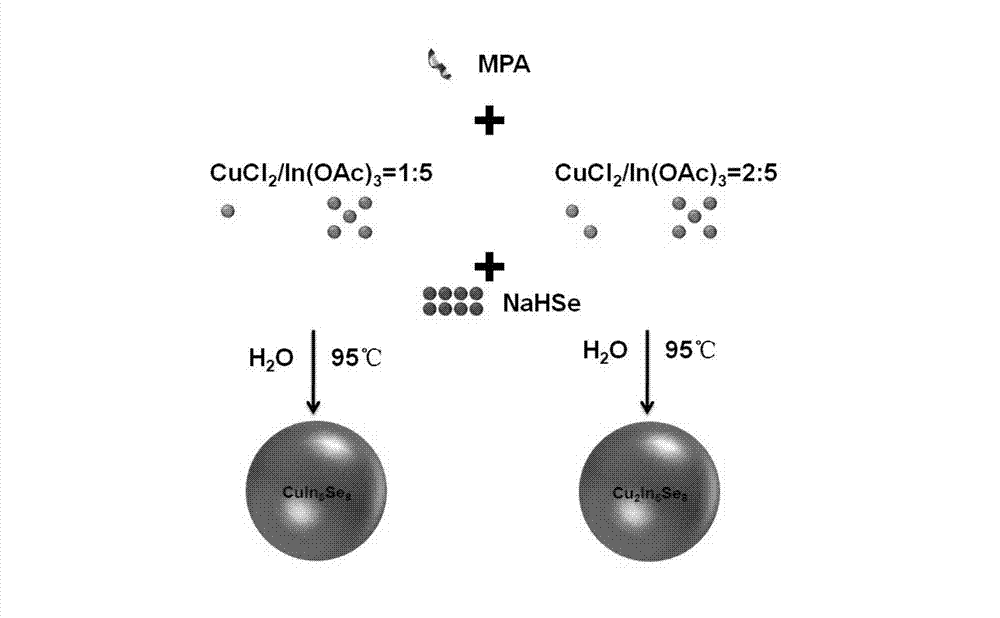

[0023] In this embodiment, a method for preparing near-infrared copper indium selenide quantum dots comprises the following steps:

[0024] (1) Precursor stock solution A: Weigh 0.175g of copper chloride and dissolve it in 10ml of ultrapure water;

[0025] (2) Precursor stock solution B: Weigh 0.0583g of indium acetate and dissolve it in 10ml of ultrapure water;

[0026] (3) Precursor stock solution C: Weigh 0.212g of 3-mercaptopropionic acid and dissolve it in 10ml of ultrapure water;

[0027] (4) Precursor stock solution D: Weigh 0.03g of sodium borohydride and 0.0158g of selenium powder, dissolve in 1ml of ultrapure water, and ice-bath until colorless;

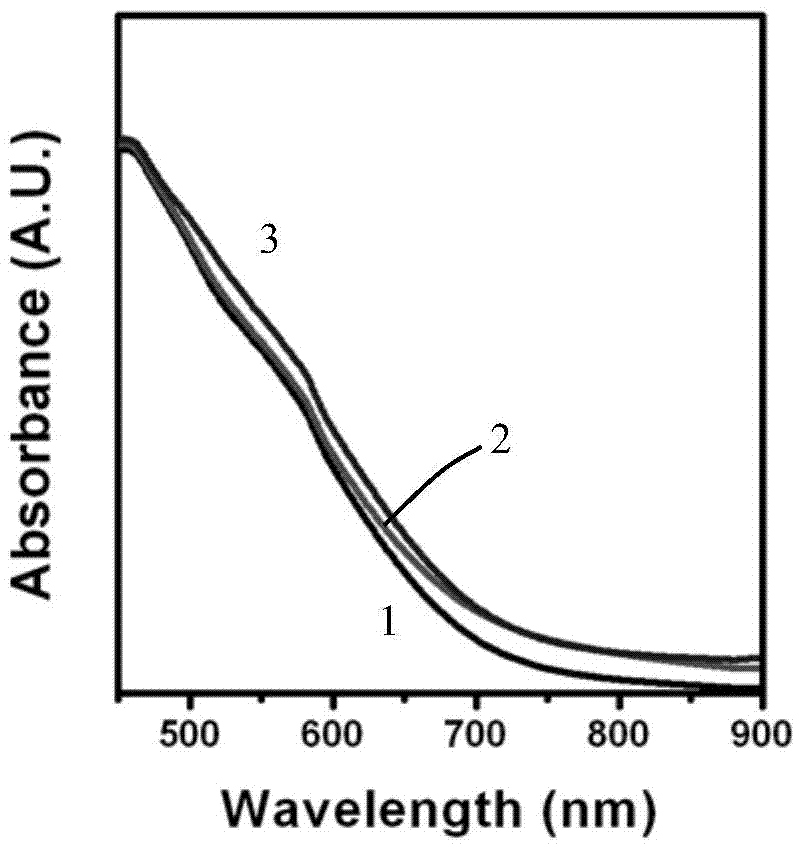

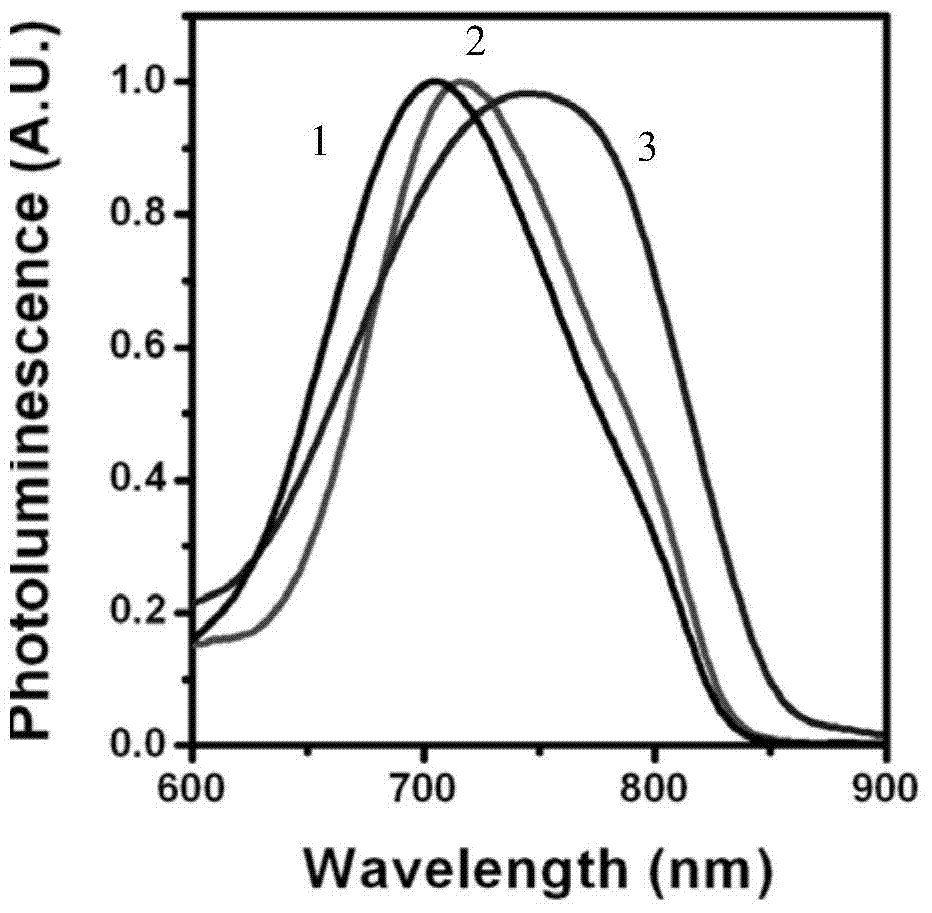

[0028] (5) Take 0.08ml of precursor stock solution A, add 1ml of precursor stock solution B, add 1ml of precursor stock solution C, set the volume to 10ml, adjust the pH value to 8.5, pass in argon gas for deoxygenation for 30min, add 0.16 ml precursor stock solution D (the molar ratio of copper chloride, indium acetate, ...

Embodiment 2

[0034] In this embodiment, a method for preparing near-infrared copper indium selenide quantum dots comprises the following steps:

[0035] (1) Precursor stock solution A: Weigh 0.175g of copper chloride and dissolve it in 10ml of ultrapure water;

[0036] (2) Precursor stock solution B: Weigh 0.0583g of indium acetate and dissolve it in 10ml of ultrapure water;

[0037] (3) Precursor stock solution C: Weigh 0.212g of 3-mercaptopropionic acid and dissolve it in 10ml of ultrapure water;

[0038] (4) Precursor stock solution D: Weigh 0.03g of sodium borohydride and 0.0158g of selenium powder, dissolve in 1ml of ultrapure water, and ice-bath until colorless;

[0039] (5) Take 0.08ml of precursor stock solution A, add 2ml of precursor stock solution B, add 1ml of precursor stock solution C, set the volume to 10ml, adjust the pH value to 8.5, pass in argon gas for deoxygenation for 30min, add 0.32 ml precursor stock solution D (the molar ratio of copper chloride, indium acetate, ...

Embodiment 3

[0045] In this embodiment, a method for preparing near-infrared copper indium selenide quantum dots comprises the following steps:

[0046] (1) Precursor stock solution A: Weigh 0.175g of copper chloride and dissolve it in 10ml of ultrapure water;

[0047] (2) Precursor stock solution B: Weigh 0.0583g of indium acetate and dissolve it in 10ml of ultrapure water;

[0048] (3) Precursor stock solution C: Weigh 0.212g of 3-mercaptopropionic acid and dissolve it in 10ml of ultrapure water;

[0049] (4) Precursor stock solution D: Weigh 0.03g of sodium borohydride and 0.0158g of selenium powder, dissolve in 1ml of ultrapure water, and ice-bath until colorless;

[0050] (5) Take 0.08ml of precursor stock solution A, add 1ml of precursor stock solution B, add 1ml of precursor stock solution C, set the volume to 10ml, adjust the pH value to 8.5, pass in argon gas for deoxygenation for 30min, add 0.16 ml precursor stock solution D (the molar ratio of copper chloride, indium acetate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com