Preparation method of II-VI family water-soluble selenide semiconductor quantum dots

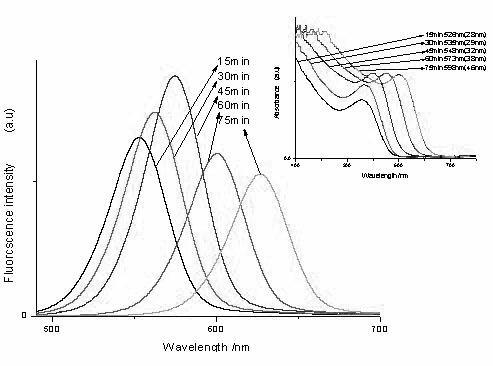

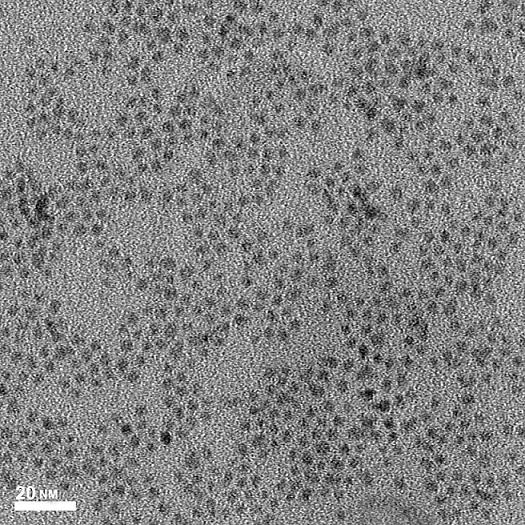

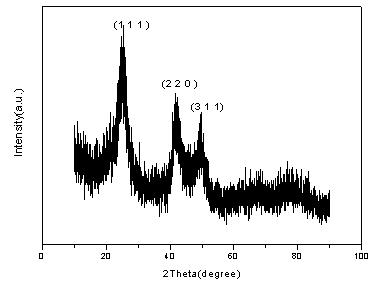

A water-soluble, quantum dot technology, used in chemical instruments and methods, luminescent materials, etc., can solve the problems of affecting fluorescence quantum efficiency, many impurities in quantum dots, and long preparation time, and achieve high fluorescence yield, uniform dispersion, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Add 0.48 mmol Cd(Ac) 2 2H 2 O was dissolved in 96ml of water, 1.2mmol of mercaptopropionic acid was added, and the pH value was adjusted to about 9.5 with 1mol / L NaOH under stirring, and the solution was transferred to an appropriate three-necked bottle.

[0030]2. Add 0.63 mmol of selenium powder and 1.26 mmol of sodium borohydride and 40 ml of deionized water into a container that has been deoxygenated with nitrogen for a period of time, and react with magnetic stirring at 0°C for 3 hours to obtain a colorless and transparent solution with white boric acid Sodium was precipitated and nitrogen protection was maintained throughout the reaction.

[0031] 3. Take 2ml of sodium borohydride solution and place it in an ice bath. When the temperature drops to 0°C, add a certain amount of 0.51mol / L sulfuric acid solution to the sodium selenium hydride solution drop by drop, and the sulfuric acid and sodium selenium hydride will immediately have a violent reaction. The rea...

Embodiment 2

[0038] 1. Add 0.48 mmol ZnCl 2 Dissolve in 96ml of water, add 1.2 mmol of mercaptoacetic acid, adjust the pH to about 9.5 with 1 mol / L NaOH under stirring, and transfer the solution to a suitable three-necked bottle.

[0039] 2. Configure 0.02M Na 2 Se solution, always under nitrogen protection during the configuration process.

[0040] 3. Take 3mlNa 2 The Se solution is placed in an ice bath. When the temperature drops to 0°C, a certain amount of 0.51mol / L sulfuric acid solution is added dropwise to the solution. The sulfuric acid and sodium selenide react violently immediately, and the selenide is formed. hydrogen gas.

[0041] 4. Under the protection of nitrogen, pass the hydrogen selenide gas directly into the container containing the mixed solution of zinc chloride and thioglycolic acid with the nitrogen. The reaction temperature is 90°C, and the solution immediately changes from colorless to light yellow. This solution is the precursor solution, and the precursor sol...

Embodiment 3

[0044] 1. Add 0.48 mmol HgSO 4 Dissolve in 96ml of water, add 1.5 mmol of mercaptoethylamine, adjust the pH value to about 9.5 with 1 mol / L NaOH under stirring, and transfer the solution to an appropriate three-necked bottle.

[0045] 2. Configure 0.02M Al 2 Se 3 solution, always under nitrogen protection during the preparation process.

[0046] 3. Take 5ml 0.02M Al 2 Se 3 The solution is placed in an ice bath. When the temperature drops to 0°C, a certain amount of 0.51mol / L sulfuric acid solution is added dropwise to the solution. The sulfuric acid and aluminum selenide react violently immediately to produce hydrogen selenide. gas.

[0047] 4. Under the protection of nitrogen, the hydrogen selenide gas is directly passed into the container containing the mixed solution of cadmium nitrate and mercaptoethylamine along with the nitrogen gas. The reaction temperature is 70 ° C. The solution immediately changes from the original colorless to light yellow. This solution is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com