Method for preparing 5-hydroxymethyl-furfural by microwave promotion

A technology of hydroxymethylfurfural and microwave, applied in the field of ionic liquid catalytic system, can solve the problems of lack of environmental friendliness, high efficiency, low-cost effective separation, continuous production, unfavorable HMF industrial production, large amount of silica gel usage, etc., to achieve catalyst and The effect of less solvent consumption, low cost, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

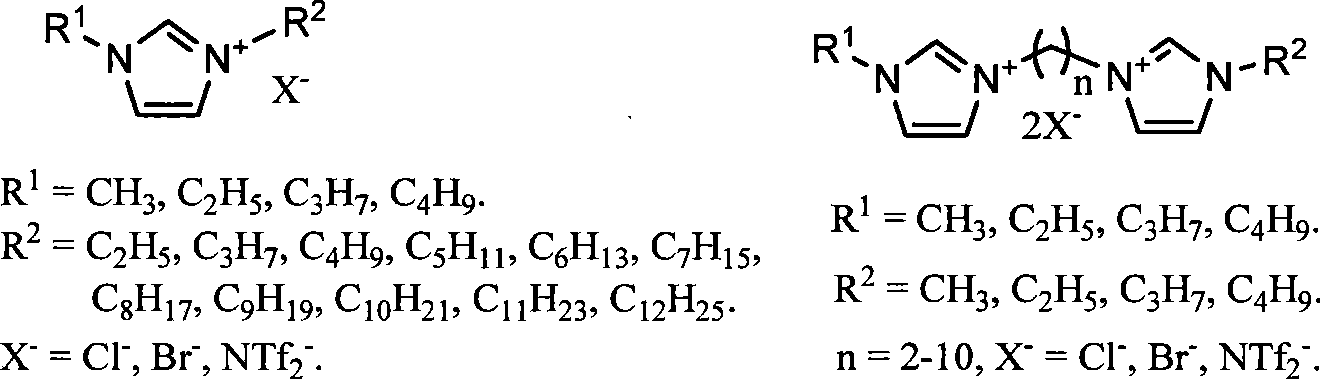

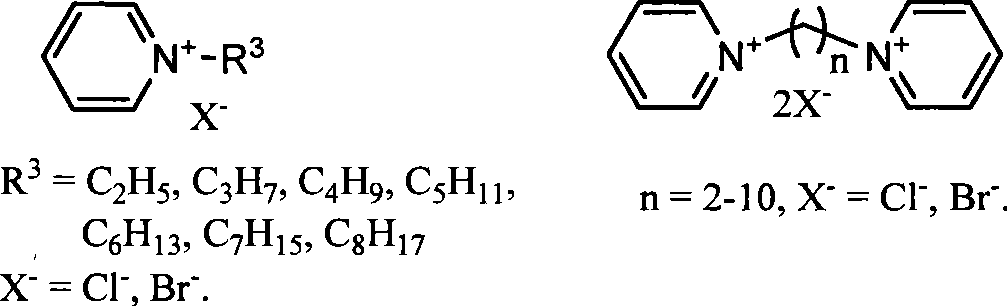

[0034] Preparation of ionic liquid solvent: refer to literature (Li C, Zhao Z.Adv.Synth.Catal.2007, 349, 1847; Webb P B, Sellin M F, Kunen TE, et al.J.Am.Chem.Soc.2003, 125 , 15577; Noda A, Watanabe M.Electrochimica Acta.2000, 45, 1265; Sheldrake G N, Schleck D.Green Chem.2007, 9, 1044.) and patent (WO 00 / 16902) prepared and purified dozens of pairs The six-carbon sugar or the ionic liquid containing six-carbon sugar biomass with strong dissolving ability is used for the implementation of the patent of the present invention.

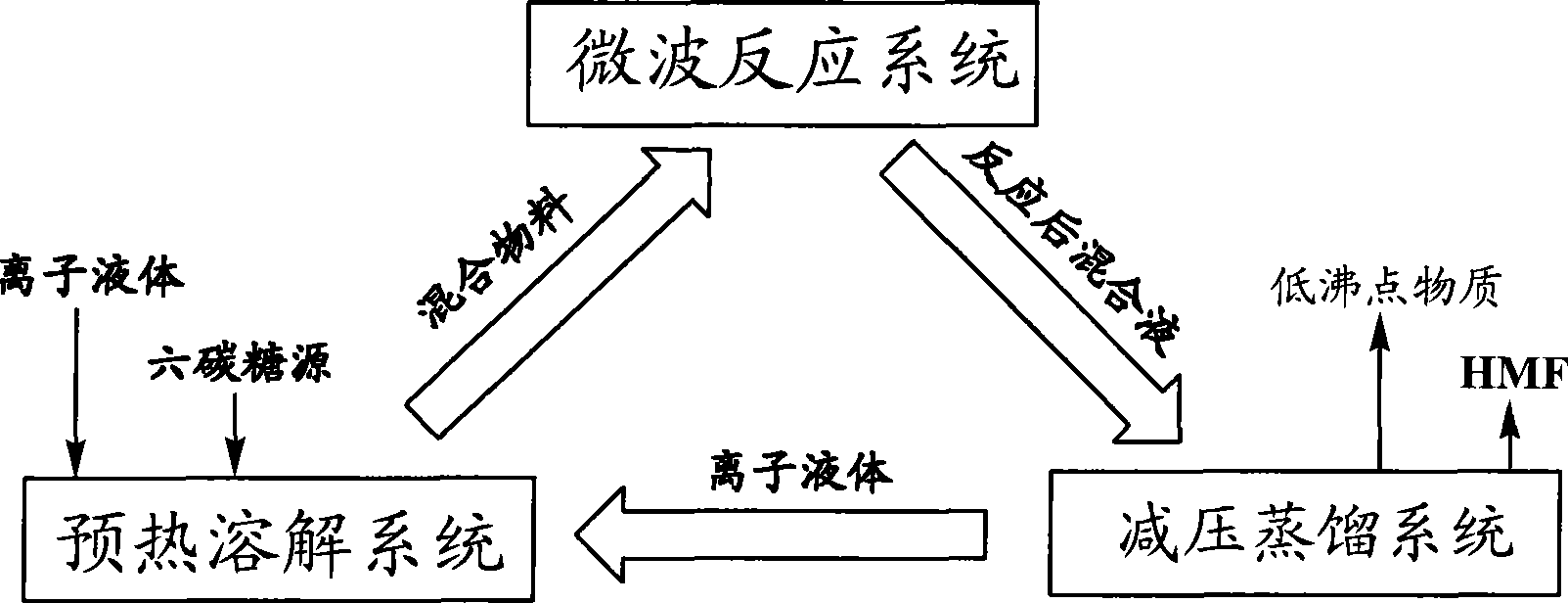

[0035] Selective dehydration of six-carbon sugar or six-carbon sugar source biomass under microwave radiation to prepare HMF comprises the following steps:

[0036] ①Dissolve six-carbon sugar or biomass containing six-carbon sugar in a preheating dissolution system at 50°C to 100°C;

[0037] ②Transfer the aforementioned mixture to a microwave reaction system and react under microwave radiation conditions. The rated frequency used for microwave radiation...

Embodiment 1

[0042] 20 g of ionic liquid [C 4 MIm]Cl and 10 grams of fructose were heated to 100°C in a preheating dissolving system, and fully dissolved; the liquid material was transferred to a microwave reaction system, and reacted for 2 minutes under microwave radiation (frequency 2450MHz); Distillation device, depressurize to 5KPa, distill and remove low boiling point substances; continue to depressurize to 133Pa, distill to collect 114 ° C ~ 116 ° C fractions, obtain 6.6 grams of dark yellow liquid product, the nuclear magnetic resonance (NMR) analysis data of this product are: 1 H NMR (400MHz, CDCl 3 ): δ 9.49(s, 1H), 7.20(d, 1H), 6.48(d, 1H), 4.65(s, 2H); 13 C NMR (100MHz, CDCl 3 ): δ 178.2, 161.6, 152.5, 123.9, 110.4, 57.7. The measured data of the product is completely consistent with the NMR data obtained by using the HMF reagent provided by Sigma, and then analyzed by ultraviolet-visible spectroscopy, it is found that the absorption peak is 282nm, which is consistent with th...

Embodiment 2

[0045] 1 g of ionic liquid [C 4 MIm]Cl and 0.1 gram of fructose are heated to 80°C in the preheating dissolving system, fully dissolved; the liquid material is transferred to the microwave reaction system, and reacted for 60 seconds under the microwave radiation condition of power 400W and frequency 2450MHz; take 0.01 gram The sample was immediately quenched with cold water, and the resulting aqueous solution was analyzed by a standard curve method at 282 nm with a UV-visible spectrophotometer, and the yield of HMF was determined to be 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com