Method of Adding Zirconium Carbonate to Electrolyte to Improve Wear Resistance of Micro-arc Oxidation Film on Near-α Titanium Alloy

A micro-arc oxidation, zirconium carbonate technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of complex equipment, poor coating effect, easy damage, etc. Effects of reduced roughness and increased growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

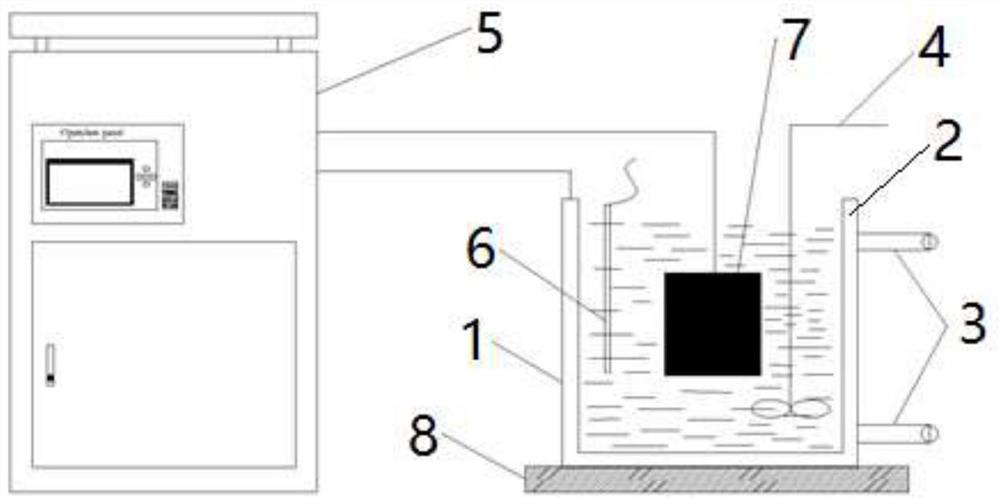

Method used

Image

Examples

Embodiment Construction

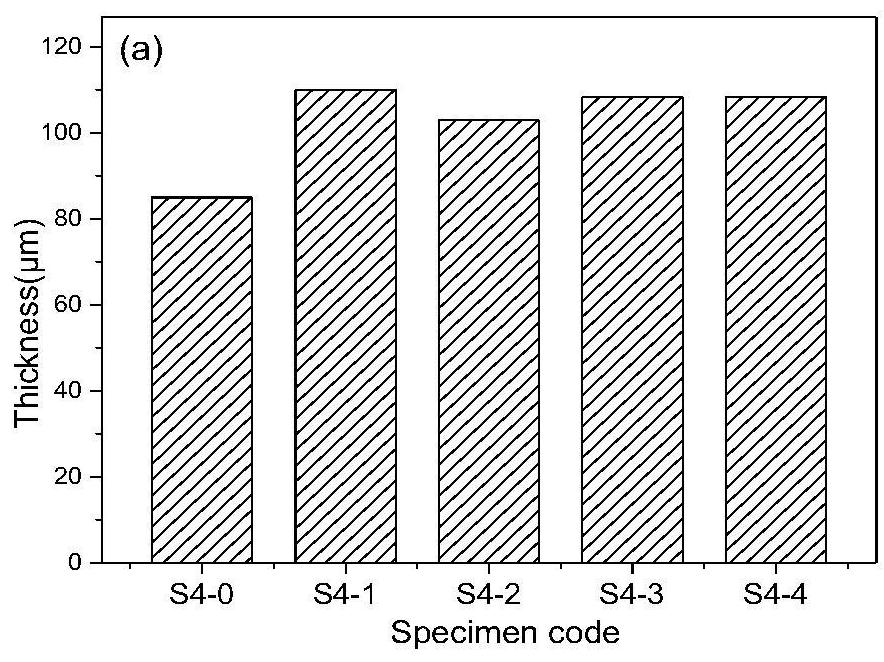

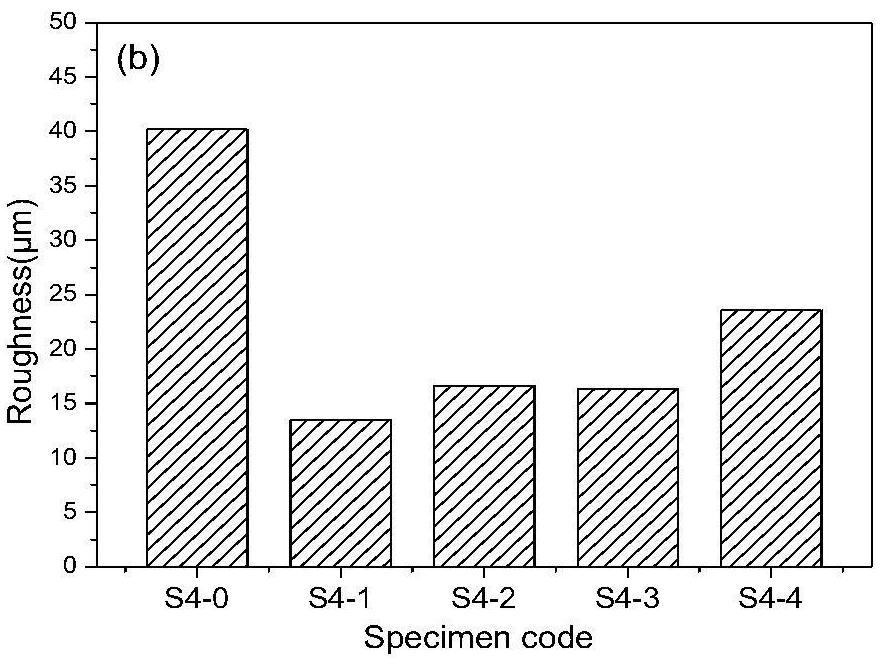

[0057] The first part, the addition of zirconium carbonate to the electrolyte to prepare the micro-arc oxidation film of near-alpha titanium alloy

[0058] 1. Preparation of near-alpha titanium alloy

[0059] The substrate sample was selected as Ti-5Al-1V-1Sn-4Zr-0.8Mo alloy (preliminary research results showed that the film layer adhesion and wear resistance obtained after micro-arc oxidation of this alloy were better), and the preparation method was vacuum automatic Vacuum consumable melting is carried out in a consumable arc melting furnace (VAR). Inductively coupled plasma atomic emission spectrometry was used to detect and analyze the actual composition of the ingot prepared by smelting. The actual composition is shown in Table 1. From the test results, the measured value of the chemical composition of the ingot is close to the nominal composition of the alloy, which meets the experimental requirements.

[0060] Table 2-1 Chemical Composition of Alloys (wt.%)

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com