Polymer cross-linking agent based on polyhedral oligomeric silsesquioxane structure

A technology of silsesquioxane and cross-linking agent, which is applied in the direction of silicon organic compounds, can solve the problems of many by-products, cumbersome preparation methods, and low yield, and achieve convenient operation, simple preparation process, and improved cross-linked structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

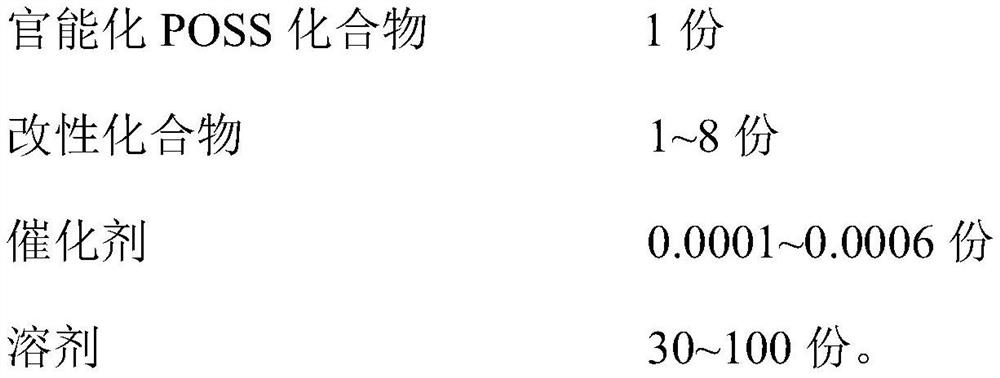

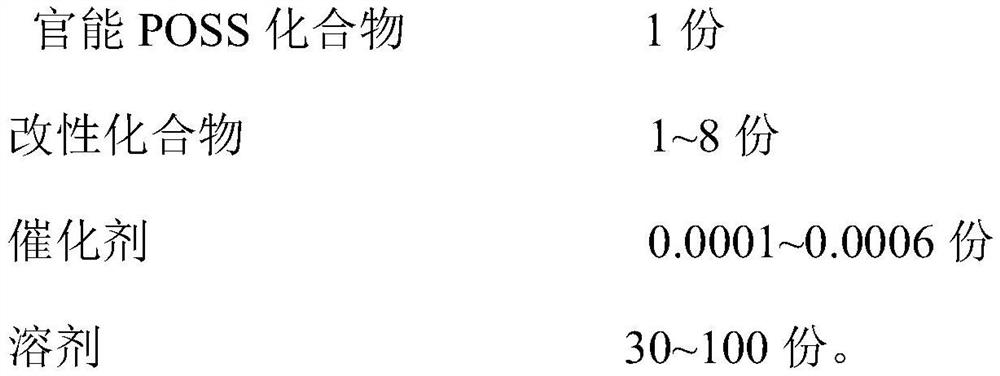

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of functionalized POSS pre-reaction solution

[0024] Add 40g of toluene to the four-necked flask, slowly add 1g of octahydro-based POSS at room temperature, pass N 2 Protect and stir slowly; after the addition is complete, raise the temperature to 50°C and stir rapidly for 1.5h until the solution is colorless or light yellow and transparent. Naturally cooled to room temperature, 0.00015 g of chloroplatinic acid catalyst was added thereto to obtain a POSS pre-reaction liquid.

[0025] (2) Preparation of POSS-based crosslinking agent

[0026] Mix and dissolve 3g of vinyl silicone oil and 30g of toluene, and slowly add it dropwise to the POSS pre-reaction solution at room temperature. After the addition is complete, N 2 Under protection, the temperature was raised to reflux for 20 h. After the reaction was completed, the catalyst was adsorbed and removed by activated carbon, and the solvent was distilled off under reduced pressure to obtain a light yell...

Embodiment 2

[0028] (1) Preparation of functionalized POSS pre-reaction solution

[0029] Add 40g of toluene to the four-necked flask, slowly add 1g of octahydro-based POSS at room temperature, pass N 2 Protect and stir slowly; after the addition is complete, raise the temperature to 50°C and stir rapidly for 1.5h until the solution is colorless or light yellow and transparent. Naturally cooled to room temperature, 0.0002 g of a chloroplatinic acid catalyst was added thereto to obtain a POSS pre-reaction liquid.

[0030] (2) Preparation of POSS-based crosslinking agent

[0031] Mix and dissolve 1.8g vinyltrimethoxysilane and 20g toluene, slowly add dropwise to the POSS pre-reaction solution at room temperature, after the dropwise addition, N 2 Under protection, the temperature was raised to reflux for 18 hours. After the reaction was completed, the catalyst was adsorbed and removed by activated carbon, and the solvent was distilled off under reduced pressure to obtain a light yellow liq...

Embodiment 3

[0033] (1) Preparation of functionalized POSS pre-reaction solution

[0034] Add 30g of tetrahydrofuran into the four-neck flask, slowly add 1g of octahydroPOSS at room temperature, and pass N 2 Protect and stir slowly; after the addition is complete, raise the temperature to 60°C and stir rapidly for 2 hours until the solution is colorless or light yellow and transparent. Naturally cooled to room temperature, 0.0003 g of chloroplatinic acid catalyst was added thereto to obtain a POSS pre-reaction liquid.

[0035] (2) Preparation of POSS-based crosslinking agent

[0036] Mix and dissolve 1.5g allyl glycidyl ether and 30g tetrahydrofuran, and slowly add it dropwise to the POSS pre-reaction solution at room temperature. After the dropwise addition, N 2 Under protection, the temperature was raised to reflux for 24 hours. After the reaction was completed, the catalyst was adsorbed and removed by active carbon, and the solvent was distilled off under reduced pressure to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com