Water-based acrylic amino baking paint and preparation method thereof

A technology of acrylic amino and acrylic resin, applied in the field of coatings, can solve the problems of poor water resistance and weather resistance, easy to breed bacteria, poor impact resistance, etc., and achieve poor impact resistance, slow curing speed, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

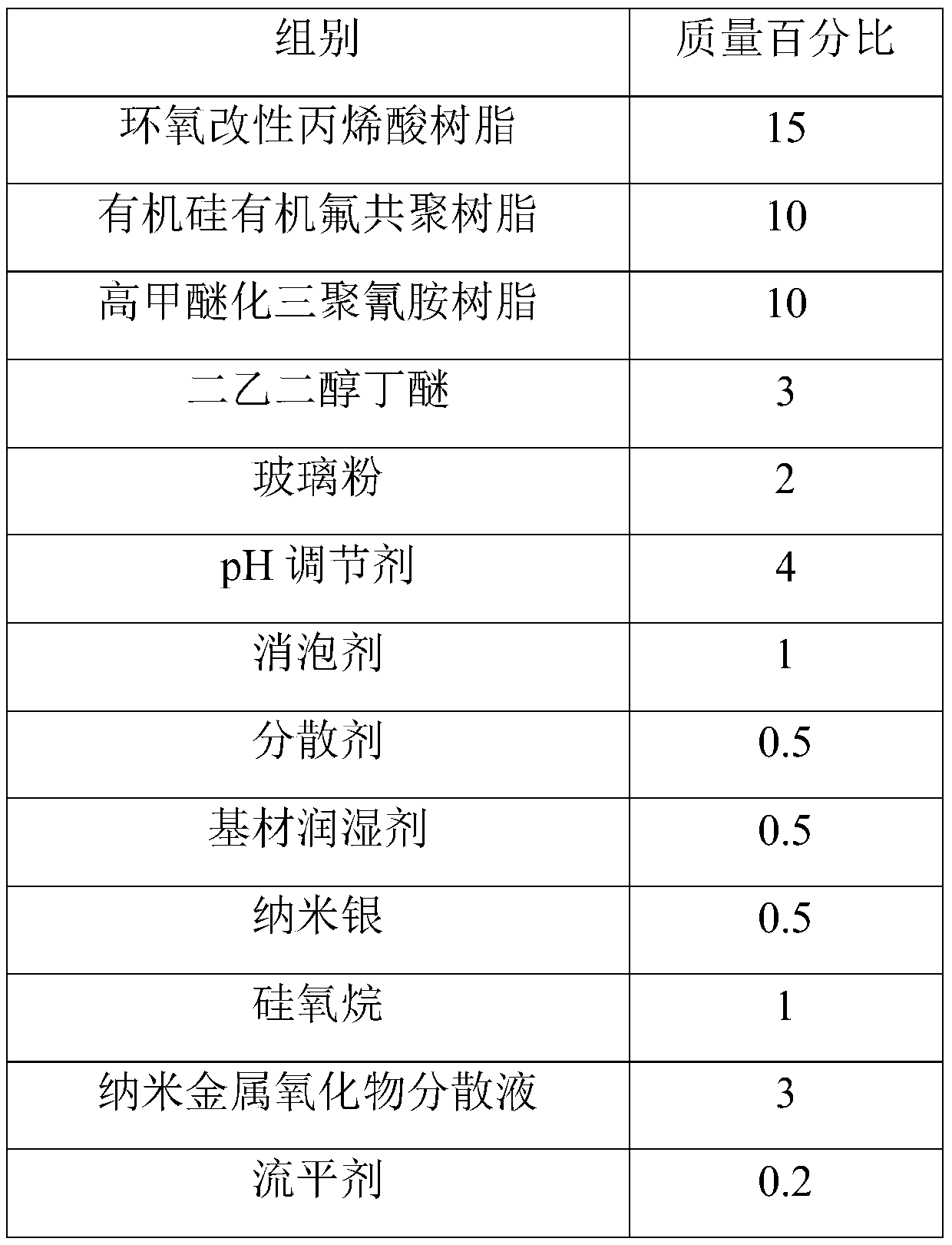

[0039] A kind of waterborne acrylic acid amino stoving varnish, comprises the component of following mass percentage:

[0040]

[0041]

[0042] Wherein, the epoxy-modified acrylic resin uses ZTC-018 of Hunan Zhitu Environmental Protection Technology Co., Ltd.; the organosilicon-organic fluorine copolymer resin is WS-1680 of Wuxi Shengjing Environmental Protection New Material Co., Ltd.; the high methyl ether The melamine resin is CYMEL 303LF; the glass powder is the VX-SP of Japan Longsen Company; the pH regulator is the dimethylethanolamine of BASF, Germany; the defoamer is Tego Antifoam 1015 of Digao; Tego's dispersant DISPERS 757W; the substrate wetting agent is BYK-346 from BYK; the nano-silver is JDGKP-003 from Jinda Nano Technology Co., Ltd.; the siloxane is WS from Wuxi Shengjing Environmental Protection New Material Co., Ltd. -1160; the nanometer metal oxide dispersion liquid is BYK3600 of BYK; the leveling agent is Glide 450 of Tego; the pigment is titanium d...

Embodiment 2

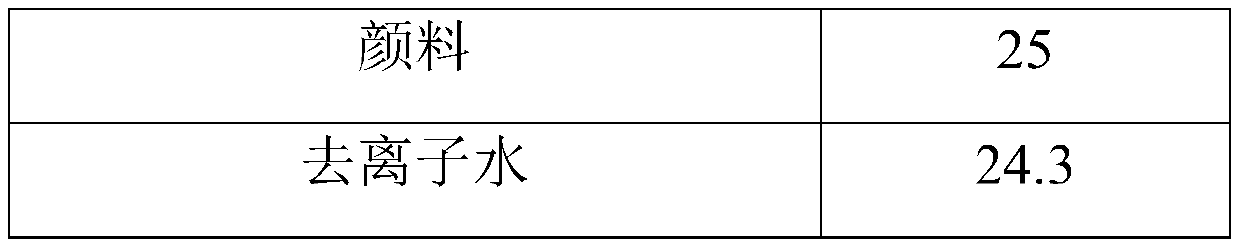

[0047] A kind of waterborne acrylic acid amino stoving varnish, comprises the component of following mass percentage:

[0048]

[0049]

[0050] Wherein, the epoxy-modified acrylic resin uses ZTC-018 of Hunan Zhitu Environmental Protection Technology Co., Ltd.; the organosilicon-organic fluorine copolymer resin is WS-1680 of Wuxi Shengjing Environmental Protection New Material Co., Ltd.; the high methyl ether The melamine resin is CYMEL 303LF; the glass powder is the VX-SP of Japan Longsen Company; the pH regulator is the dimethylethanolamine of BASF, Germany; the defoamer is Tego Antifoam 1015 of Digao; Tego's dispersant DISPERS 757W; the substrate wetting agent is BYK-346 from BYK; the nano-silver is JDGKP-003 from Jinda Nano Technology Co., Ltd.; the siloxane is WS from Wuxi Shengjing Environmental Protection New Material Co., Ltd. -1160; the nanometer metal oxide dispersion is BYK3600 of BYK; the leveling agent is Glide 450 of Tego; the pigment is iron red.

[005...

Embodiment 3

[0055] A kind of waterborne acrylic acid amino stoving varnish, comprises the component of following mass percentage:

[0056] group mass percentage Epoxy Modified Acrylic Resin 30 Silicone organofluorine copolymer resin 5 Highly etherified melamine resin 4 Diethylene glycol butyl ether 5 glass powder 4 pH regulator 2 Defoamer 0.5 Dispersant 1.5 Substrate wetting agent 0.3 nano silver 1 Silicone 2 Nano metal oxide dispersion 5 leveling agent 0.4 pigment 10 Deionized water 29.3

[0057] Wherein, the epoxy-modified acrylic resin uses ZTC-018 of Hunan Zhitu Environmental Protection Technology Co., Ltd.; the organosilicon-organic fluorine copolymer resin is WS-1680 of Wuxi Shengjing Environmental Protection New Material Co., Ltd.; the high methyl ether The melamine resin is CYMEL 303LF; the glass powder is the VX-SP of Japan Longsen Company; the pH regulator is the dimethylethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com