Wet strength agent, and preparation method and application of wet strength agent

A technology of wet strength agent and catalyst, which is applied in the direction of enhancer addition, etc., can solve the problems of no significant improvement in the effect of humidification strength, improve retention performance, solve problems of excessively high cationic charge density, prevent swelling and water absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

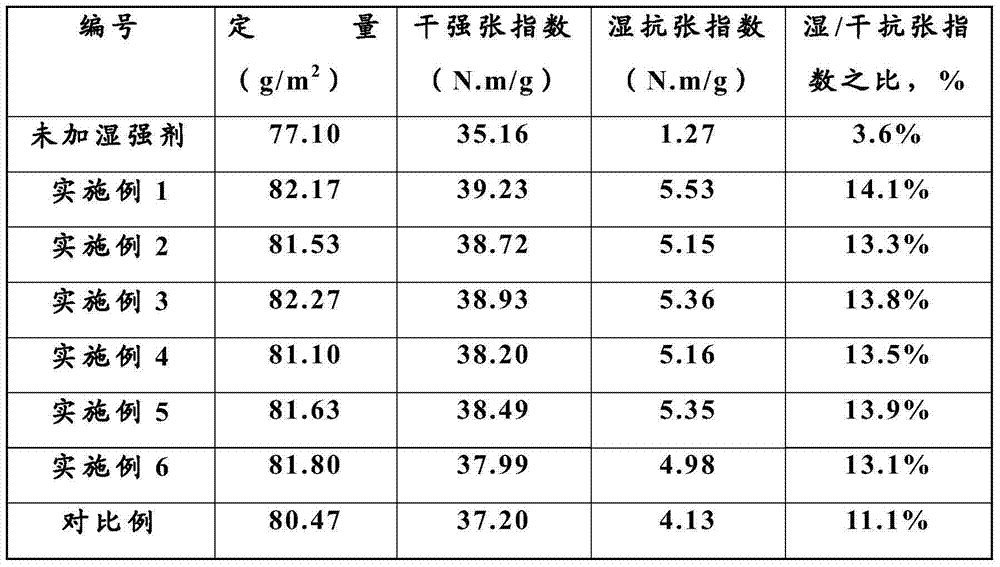

Examples

Embodiment 1

[0043] (1) In a 500ml four-necked flask with a stirrer, a thermometer and a reflux condenser, add successively a 40% linear polyacrylic acid aqueous solution (the molecular weight of the linear polyacrylic acid is 1850, and the addition amount is 0.0025mol), diethylenetriamine 0.425mol, 0.5g of 50% sulfuric acid, heated up to 135°C, and kept for 1 hour to synthesize a polyamide polyamine prepolymer A with a comb structure; add 0.36mol of adipic acid, Malay Acid anhydride 0.043mol, heat up to 175°C, keep warm for 6 hours, add deionized water, dilute the polyamide polyamine to a solid content of 50%, and obtain a wet strength agent intermediate solution B with a viscosity of 405mPa.s (25°C) ;

[0044] (2) Transfer the above-mentioned wet strength agent intermediate B to a 1-liter four-neck flask, add deionized water to adjust the solid content to 30%, raise the temperature to 35°C, and add 24 g of ammonium persulfate aqueous solution with a concentration of 1% at the same time, 8...

Embodiment 2

[0047] (1) in the 500ml four-neck flask that has stirrer, thermometer and reflux condenser, add content successively and be the linear polymaleic acid aqueous solution of 50% (the molecular weight of linear polymaleic acid is 1050, and addition is 0.005mol), 0.425mol of diethylenetriamine, 1.0g of p-toluenesulfonic acid, heated up to 140°C, and kept the temperature for 0.5 hours to synthesize a polyamide polyamine prepolymer A with a comb structure; Formic acid 0.315mol, itaconic acid 0.098mol, heat up to 180°C, heat preservation reaction for 5 hours, add deionized water, dilute the polyamide polyamine to a solid content of 50%, and obtain a wet solution with a viscosity of 380mPa.s (25°C). Strong agent intermediate solution B;

[0048] (2) Transfer the above-mentioned wet strength agent intermediate B to a 1-liter four-neck flask, add deionized water to adjust the solid content to 30%, raise the temperature to 40°C, and add 24 g of ammonium persulfate aqueous solution with a ...

Embodiment 3

[0051] (1) in the 500ml four-neck flask that has stirrer, thermometer and reflux condenser, add content successively and be the linear polyitaconic acid aqueous solution of 50% (the molecular weight of linear polyitaconic acid is 625, and addition is 0.01mol), 0.285mol of triethylenetetramine, 0.15mol of hexamethylenediamine, 2.0g of dodecylbenzenesulfonic acid, heating up to 130°C, and keeping the temperature for 1 hour to synthesize polyamide polyamine prepolymer A with a comb structure; Add 0.35 mol of sebacic acid and 0.075 mol of fumaric acid to prepolymer A, raise the temperature to 160°C, keep it warm for 9 hours, add deionized water, dilute the polyamide polyamine to a solid content of 50%, and obtain a viscosity of 550mPa .s (25°C) wet strength agent intermediate solution B;

[0052] (2) Transfer the above-mentioned wet strength agent intermediate B to a 1-liter four-necked flask, add deionized water to adjust the solid content to 30%, raise the temperature to 38° C.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com