Molded foam article and method of producing molded foam article

A technology of foam molding and manufacturing method, which is applied in the direction of coating, etc., can solve the problems of rough surface, inability to obtain foaming ratio, poor appearance, etc., and achieve the effect of excellent rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

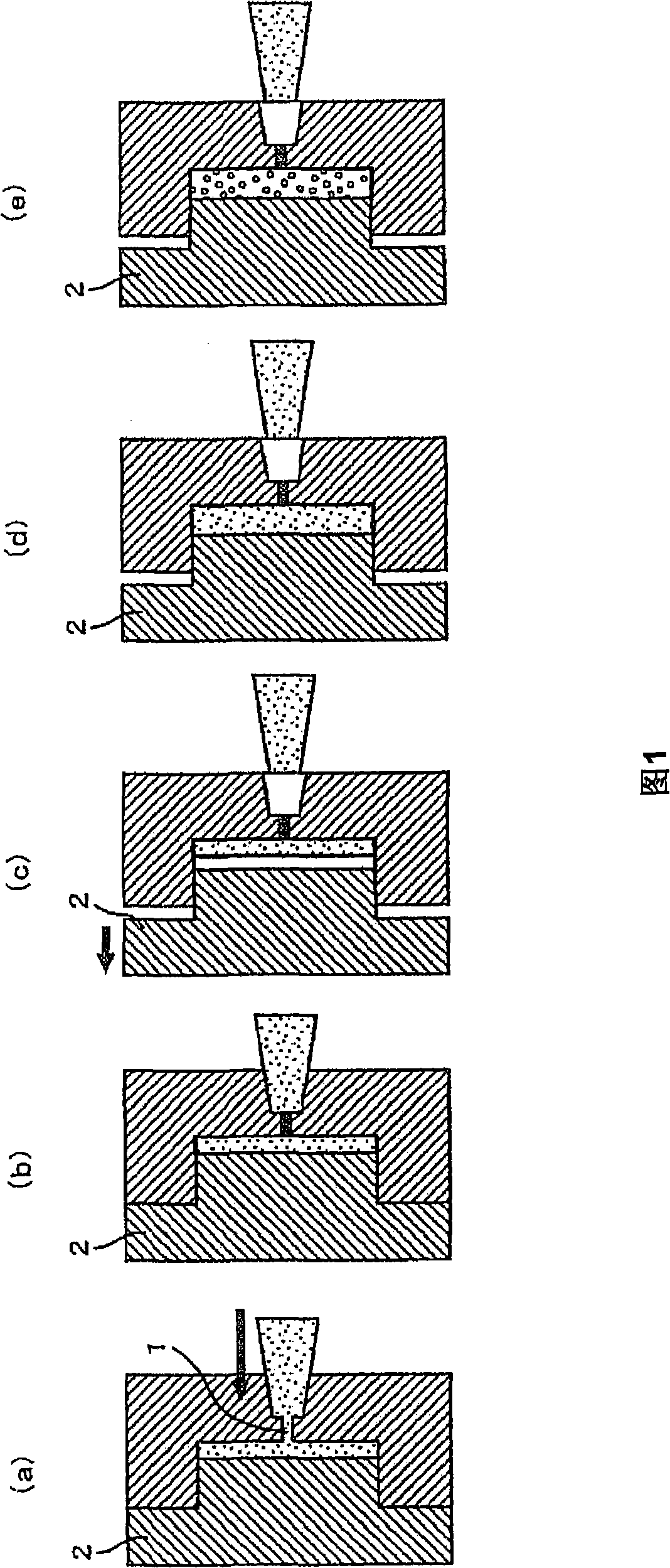

Method used

Image

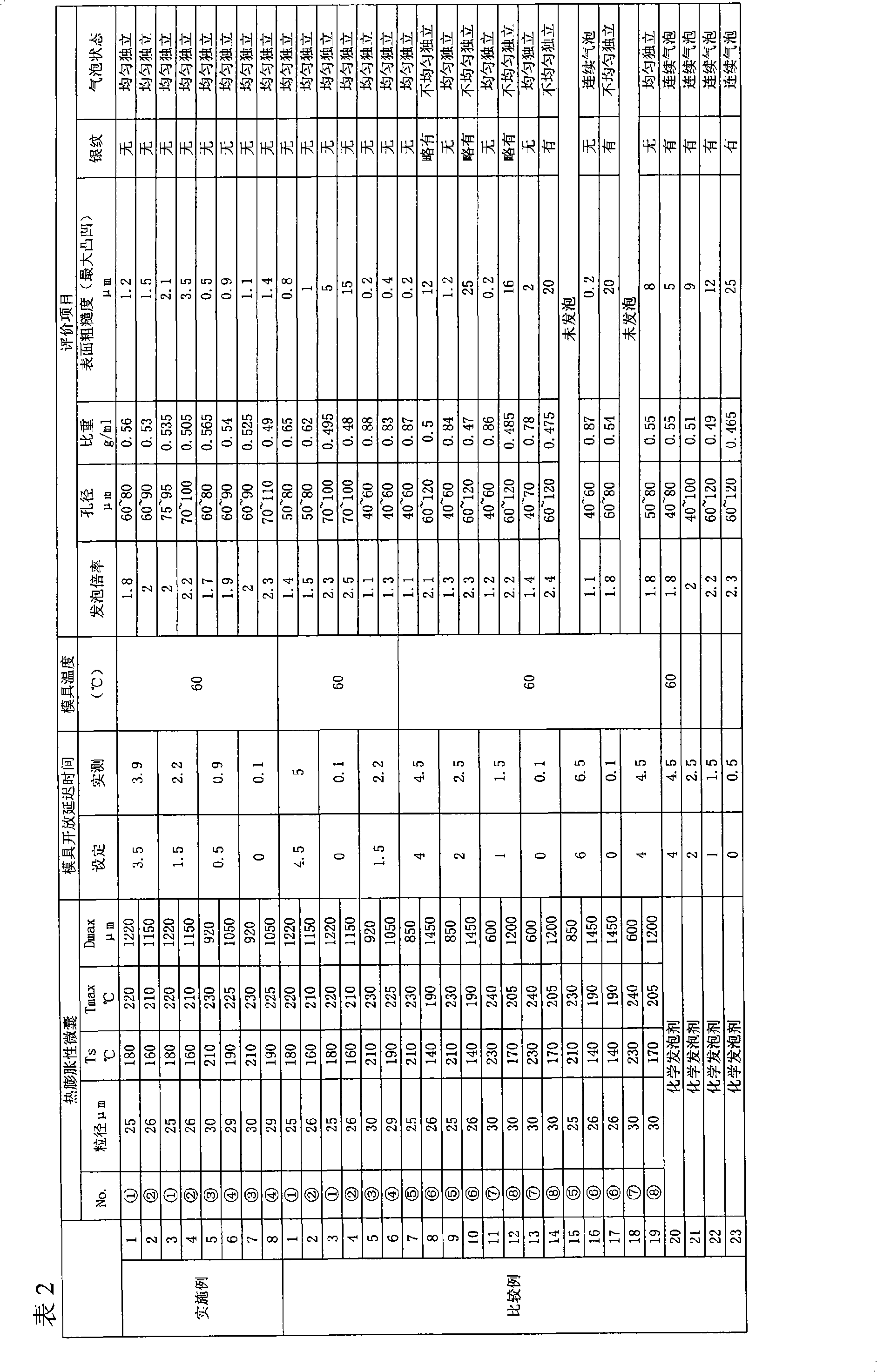

Examples

Embodiment 1~8、 comparative example 1~19

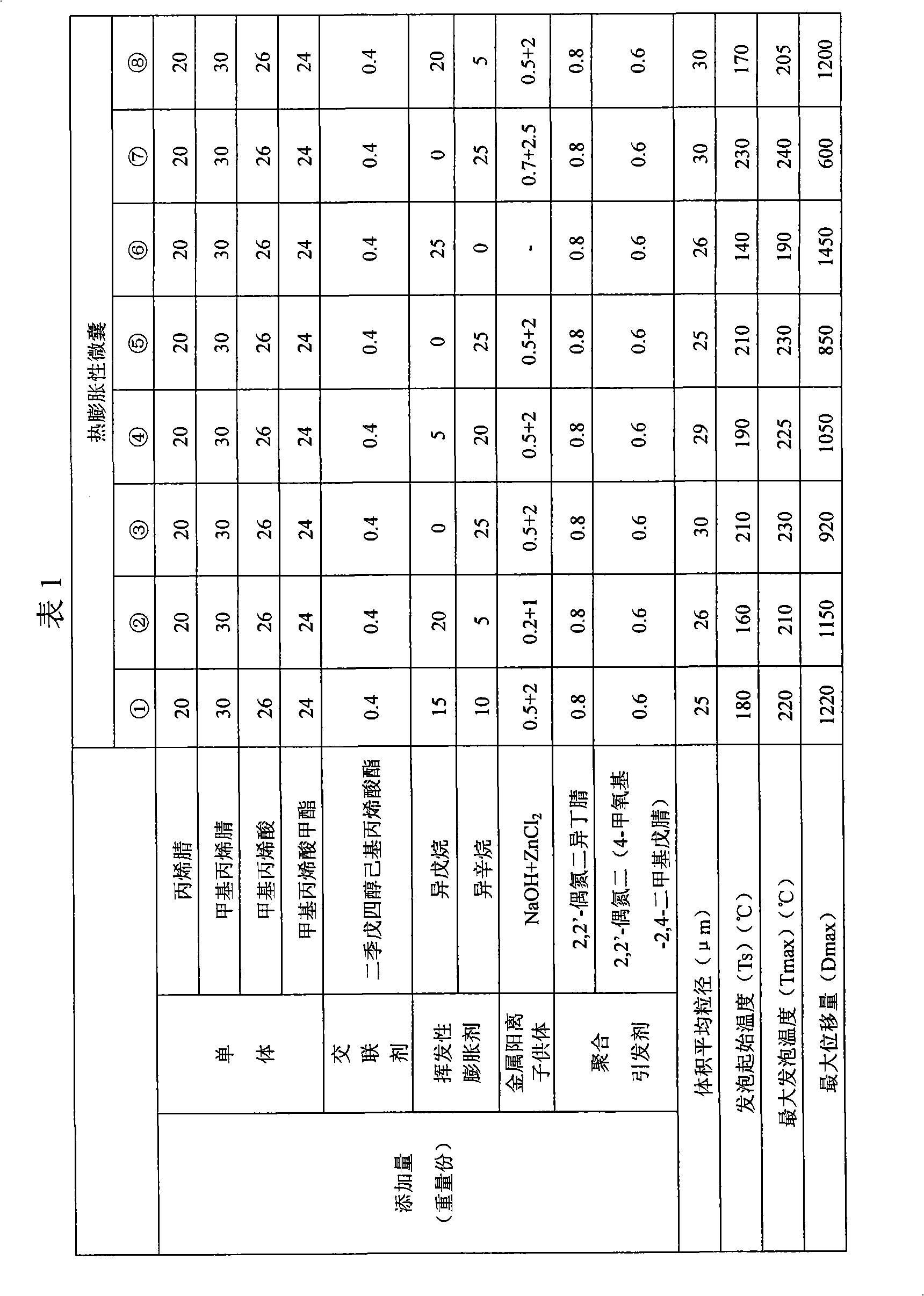

[0148] (Manufacture of heat-expandable microcapsules)

[0149] 8 L of water, 10 parts by weight of colloidal silica (manufactured by Asahi Denka Corporation) as a dispersion stabilizer, and 0.3 parts by weight of polyvinylpyrrolidone (manufactured by BASF Corporation) were put into a polymerization reaction container to prepare an aqueous dispersion medium. Afterwards, an oily mixed liquid composed of monomers, crosslinking agents, volatile expansion agents and polymerization initiators in the compounding amounts shown in Table 1 was added to the aqueous dispersion medium, and further added in the compounding amounts shown in Table 1. Metal cation donors from which to formulate dispersions. The obtained dispersion liquid was stirred and mixed with a homogenizer, charged into a pressurized polymerizer (20 L) replaced with nitrogen, pressurized (0.2 MPa), and reacted at 60° C. for 20 hours, thereby Prepare the reaction product. The obtained reaction product was repeatedly filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com