Polarization plate and optical component

A technology of polarizing plates and polarizers, which is applied in the field of polarizing plates, can solve problems such as insufficient durability and shrinkage easily caused by heat resistance tests of polarizing plates, and achieve good adhesion, superior lightness of thin sheets, and high durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0094] [Reference example 1] Production of polarizing plate

[0095] A polyvinyl alcohol film with an average degree of polymerization of about 2400, a saponification degree of 99.9 mol% or more, and a thickness of 75 μm is uniaxially stretched to 5 times in a dry type, and then immersed in pure water at 60°C for 1 Minutes, and then immersed in an aqueous solution with a weight ratio of iodine / potassium iodide / water of 0.05 / 5 / 100 at 28°C for 60 seconds. Then, it was immersed at 72 degreeC for 300 second in the aqueous solution whose weight ratio of potassium iodide / boric acid / water was 8.5 / 8.5 / 100. Next, after washing in 26 degreeC pure water for 20 seconds, it dried at 65 degreeC, and produced the polarizing plate which adsorb|sucked and oriented the iodine on the polyvinyl alcohol.

Embodiment 1

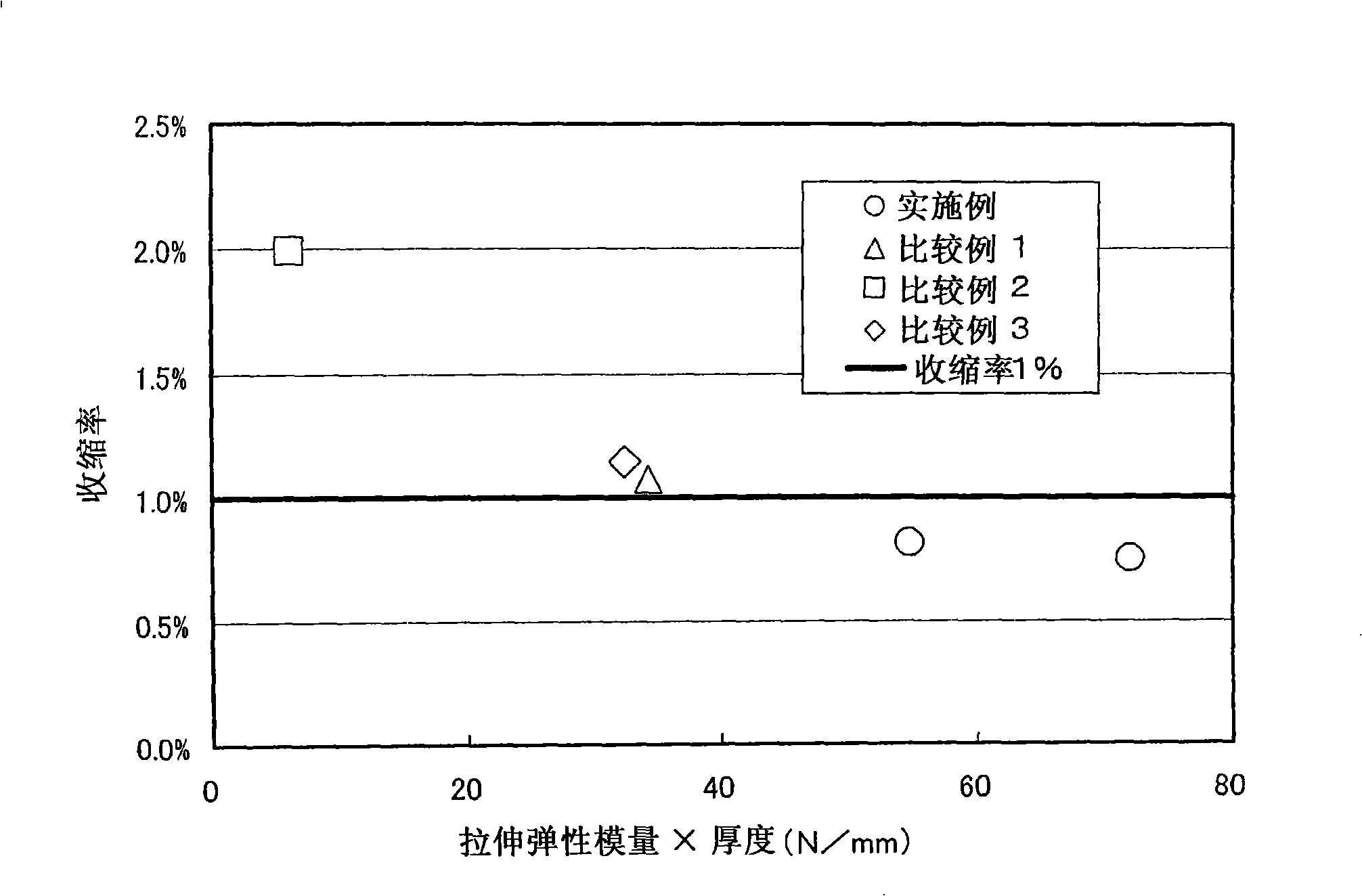

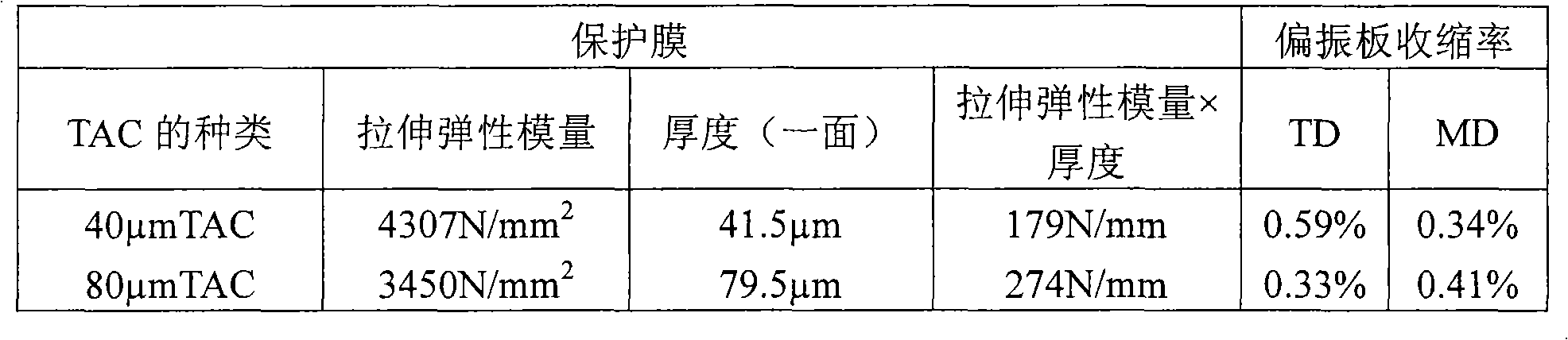

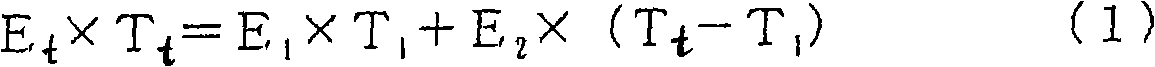

[0097] One side of the polarizing plate obtained in Reference Example 1 was coated with the above-mentioned ultraviolet curable resin composition "DN-0081" using a coater, and cured by irradiating ultraviolet rays. The same composition was also applied to the other side of the polarizer, and cured by irradiating ultraviolet rays. In this way, a polarizing plate in which protective films were formed on both surfaces of the polarizing plate was produced. The thickness of the protective film was 10.5 μm on both sides. In addition, the same composition was applied on another substrate and cured, and the tensile elastic modulus of the evaluated protective film was 6845 N / mm 2 (=MPa). Thereby, the tensile elastic modulus (N / mm 2 ) and thickness (mm) on one side is 72N / mm.

Embodiment 2

[0099] A polarizing plate was produced in the same manner as in Example 1 except that the thickness of the protective film was 8 μm on both sides. Tensile elastic modulus of protective film (N / mm 2 ) and thickness (mm) on one side is 55N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com