Run-flat tire

A run-flat tire and tire technology, which is applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc., can solve the problems of deterioration of ride comfort and increase in tire weight, so as to improve ride comfort and restrain bending , the effect of preventing fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

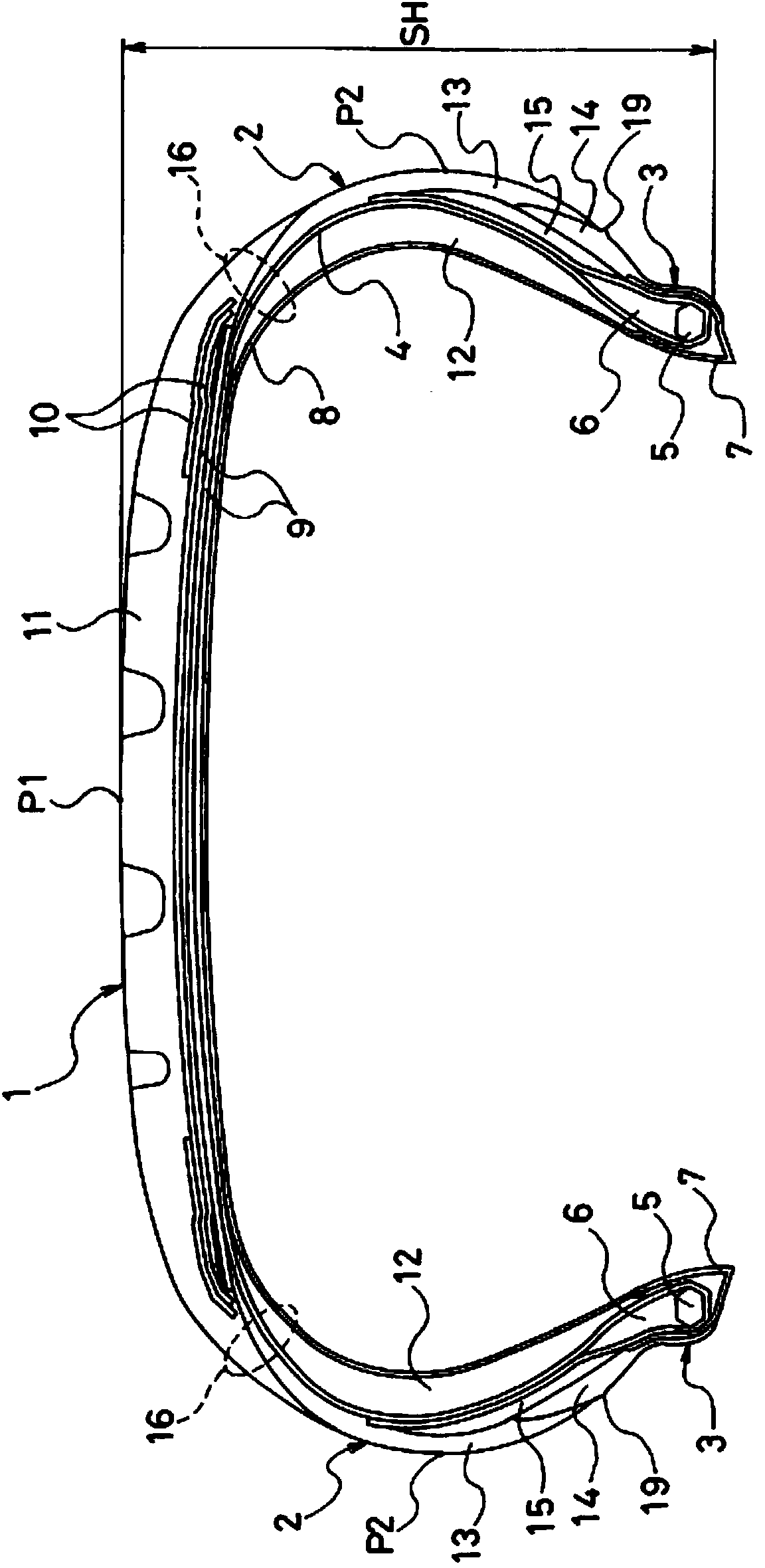

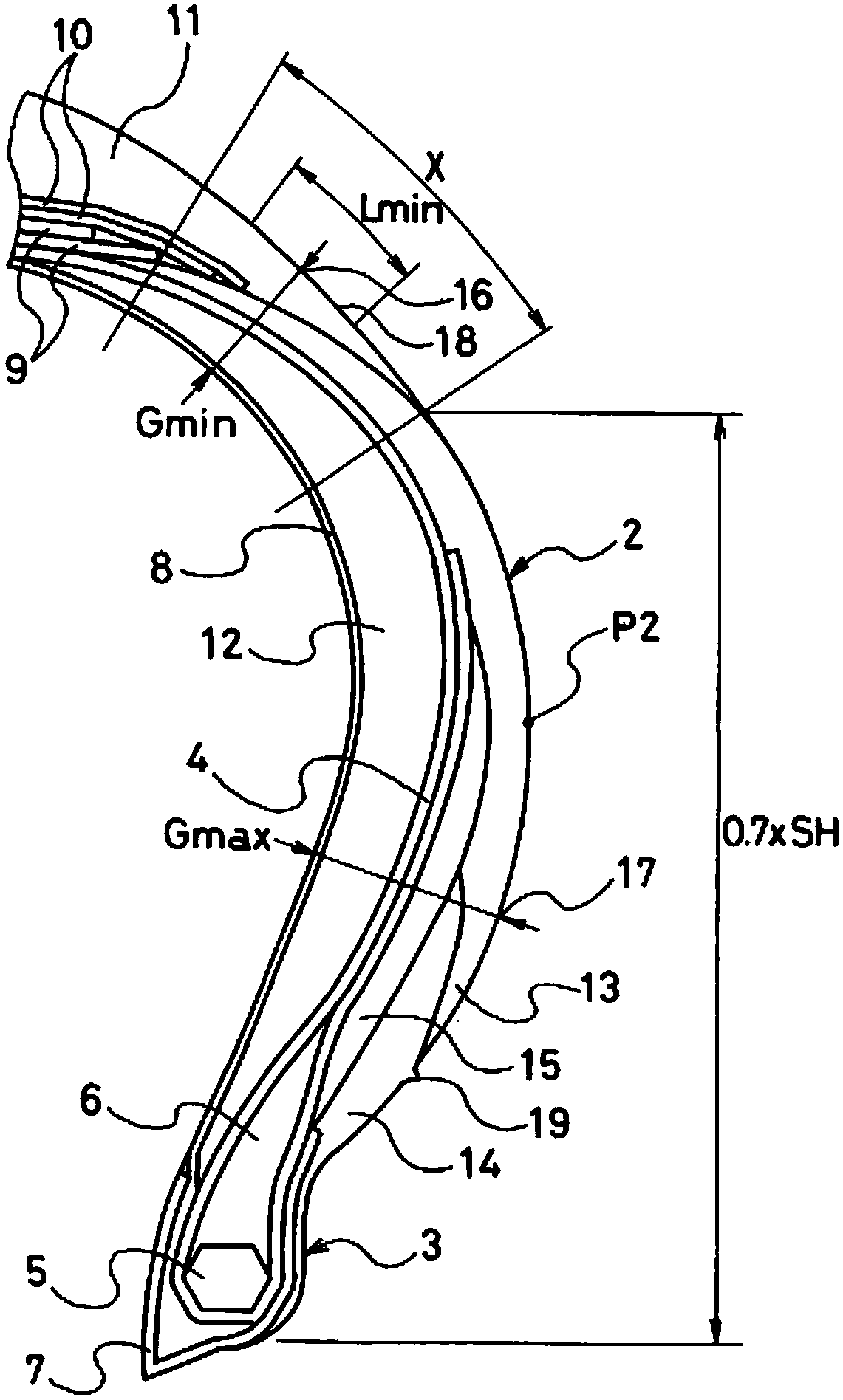

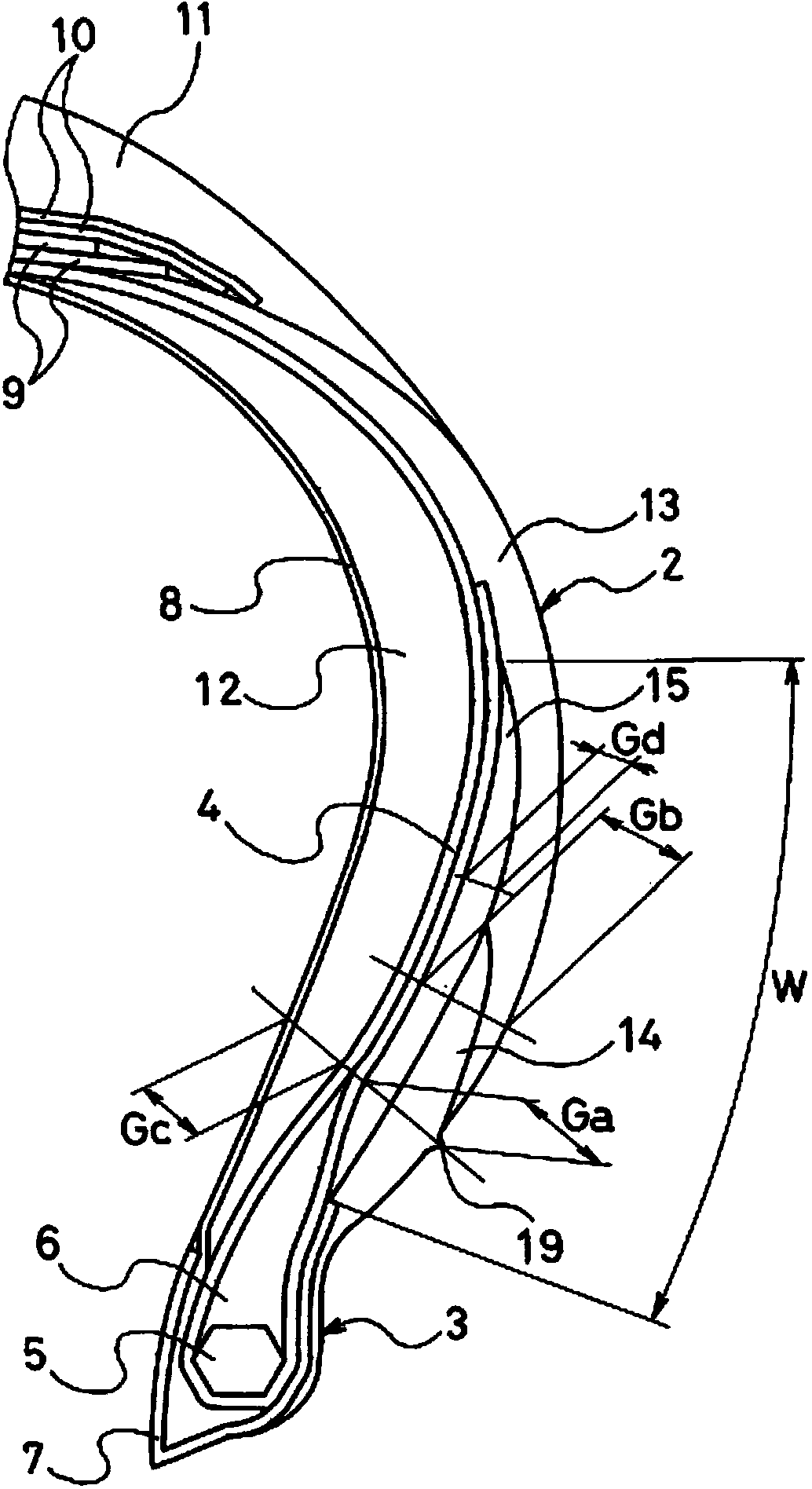

[0059] The tire size is 235 / 50R18, a carcass layer is built between a pair of bead parts, and the carcass layer is rolled up from the inside to the outside of the tire around the bead core of each bead part The bead filler is arranged on the outer peripheral side of each bead core, two belt layers are arranged on the outer peripheral side of the carcass layer of the tread portion, the belt cover layer is arranged on the outer peripheral side of these belt layers, and the tire A sidewall reinforcement layer with a crescent-shaped cross-section is arranged between the body layer and the inner liner, and an additional reinforcement layer is buried on the outside of the carcass layer in the range of 15% to 70% of the tire cross-sectional height SH. In the warranty tire, for the thickness Gmin of the minimum wall thickness part, the thickness Gmax of the maximum wall thickness part, the length Lmin of the thin wall area, the relationship between the tire section height SH and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com