B4C composite ceramic with composite structure as toughening phase and preparation method of B4C composite ceramic

A technology of composite structure and composite ceramics, which is applied in the field of B4C composite ceramics and its preparation, can solve the problems of small difference, low fracture toughness, and narrow the use range of C materials, and achieve the effect of high hardness and increased fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

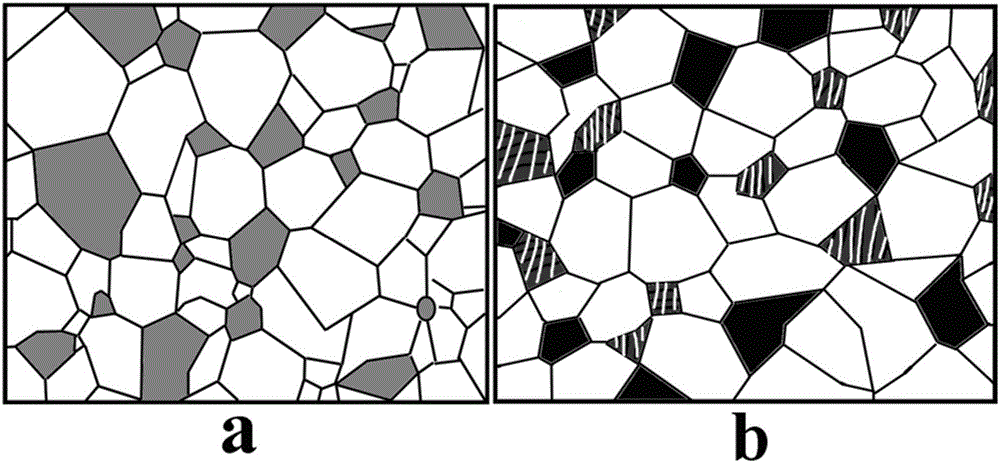

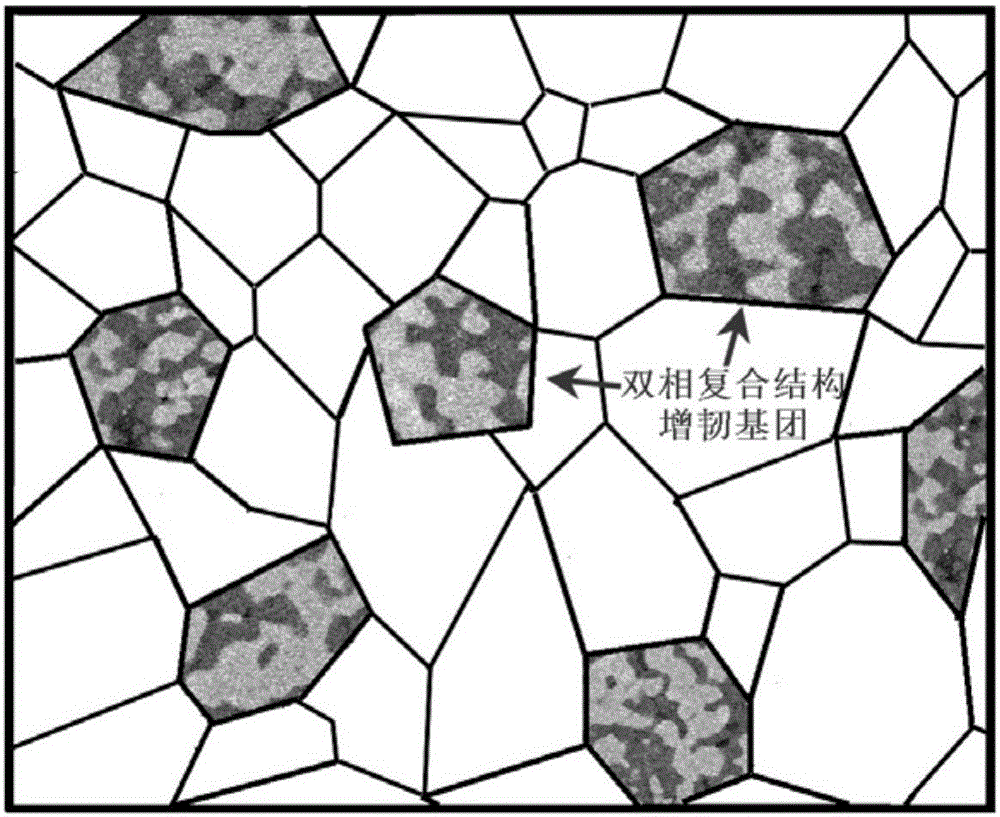

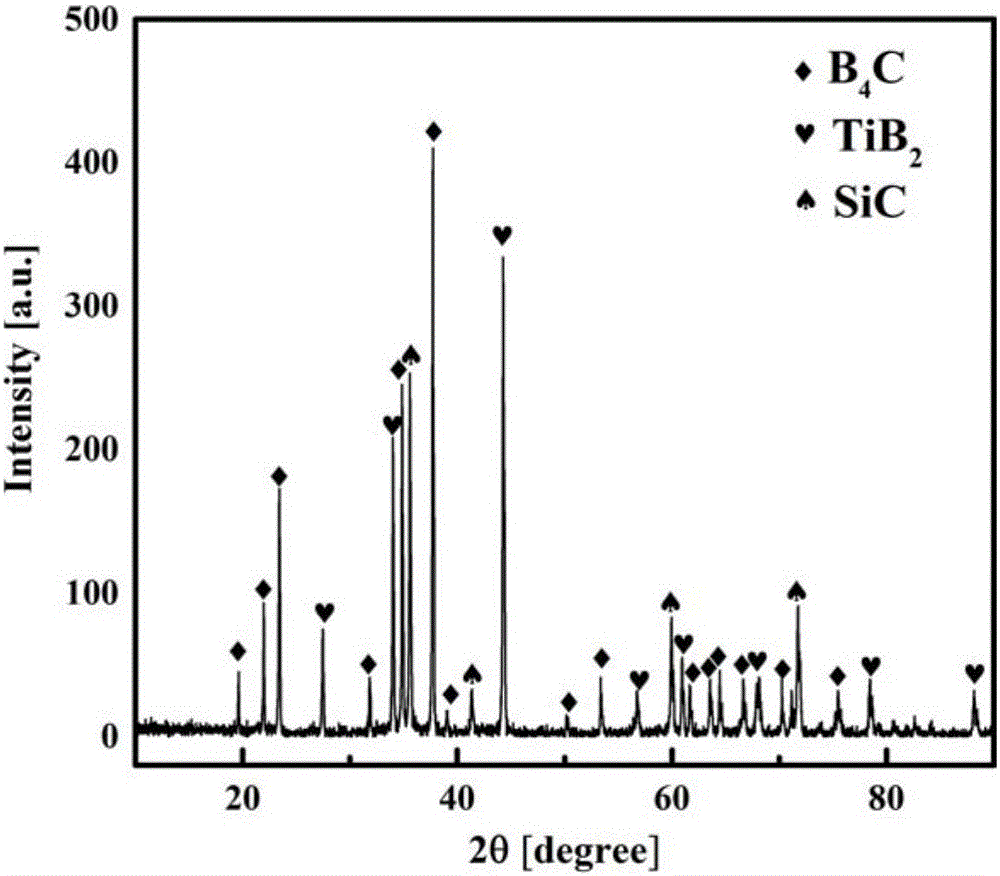

[0038] A kind of B with composite structure as toughening phase 4 C composite ceramics, to B 4 C is the matrix phase, with (TiB 2 -SiC) composite structure as a toughening phase, including by weight percent: matrix phase B 4 C 95%, toughening phase (TiB 2 -SiC) composite structure 5%, in which TiB in the toughening phase 2 The amount ratio of the substance to SiC is 2:3.

[0039] By weight percentage, the B with composite structure as toughening phase 4 C composite ceramics consist of 1.07% B 4 C (particle size is 3um, purity is 97%), 2.31% TiC (particle size is 3μm, purity is 98%) and 1.62% Si powder (particle size is 200μm, purity is 99%) as raw materials through the mechanized process, and then with 95% of the same species B 4 The C powder is mixed twice, and finally prepared by high-pressure rapid sintering technology.

[0040] B described in this example 4 C-(TiB 2 -SiC) the preparation method of composite ceramics, concrete steps comprise:

[0041] ① Weigh B b...

Embodiment 2

[0046] A kind of B with composite structure as toughening phase 4 C composite ceramics, to B 4 C is the matrix phase, with (TiB 2 -SiC) composite structure as a toughening phase, including by weight percent: matrix phase B 4 C 95%, toughening phase (TiB 2 -SiC) composite structure 5%, in which TiB in the toughening phase 2 The amount ratio of the substance to SiC is 2:3.

[0047] By weight percentage, the composite ceramic consists of 1.07% B 4 C (particle size is 2um, purity is 97%), 2.31% TiC (particle size is 1μm, purity is 99%) and 1.62% Si powder (particle size is 10μm, purity is 99%) as raw materials through the mechanized process, and then with 95% of the same species B 4 The C powder is mixed twice, and finally prepared by high-pressure rapid sintering technology.

[0048] The composite structure described in this embodiment is used as the B of the toughening phase 4 The preparation method of C composite ceramics, concrete steps comprise:

[0049] ① Weigh B by...

Embodiment 3

[0054] The difference between this example and Example 2 is that the obtained composite structure is used as the toughening phase B 4 Matrix phase B in composite ceramics 4 C 90%, toughening phase (TiB 2 -SiC) composite structure 10%, in which TiB in the toughening phase 2 The amount ratio of the substance to SiC is 2:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com