Metal slide fastener as well as surface working apparatus and surface working method thereof

A metal zipper and surface processing technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of increased surface roughness of fastener elements, easy to be oxidized and corroded, rough fastener elements, etc. The surface of the chain element is smooth, bright and resistant to oxidation and corrosion, and the effect of high lightness and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

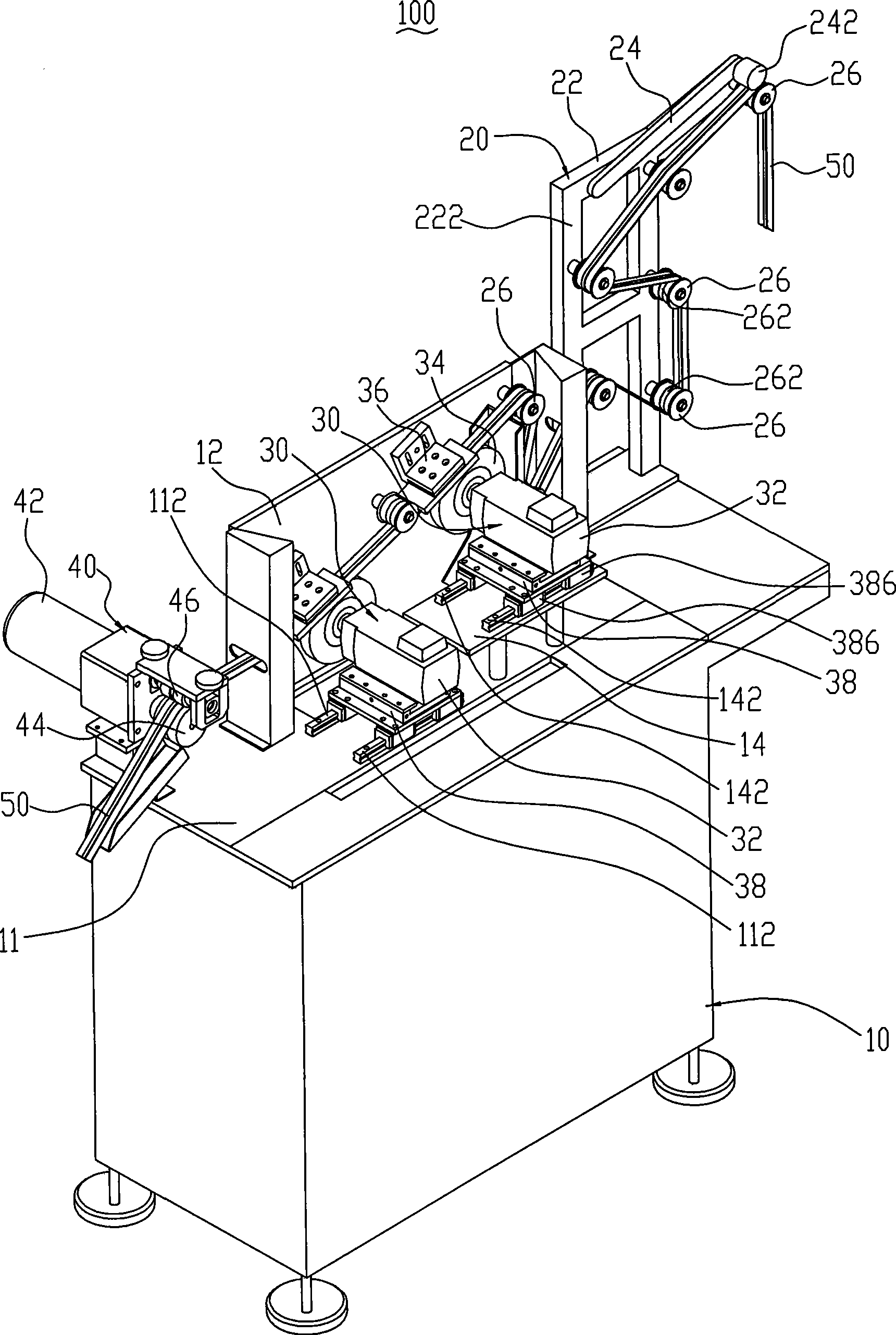

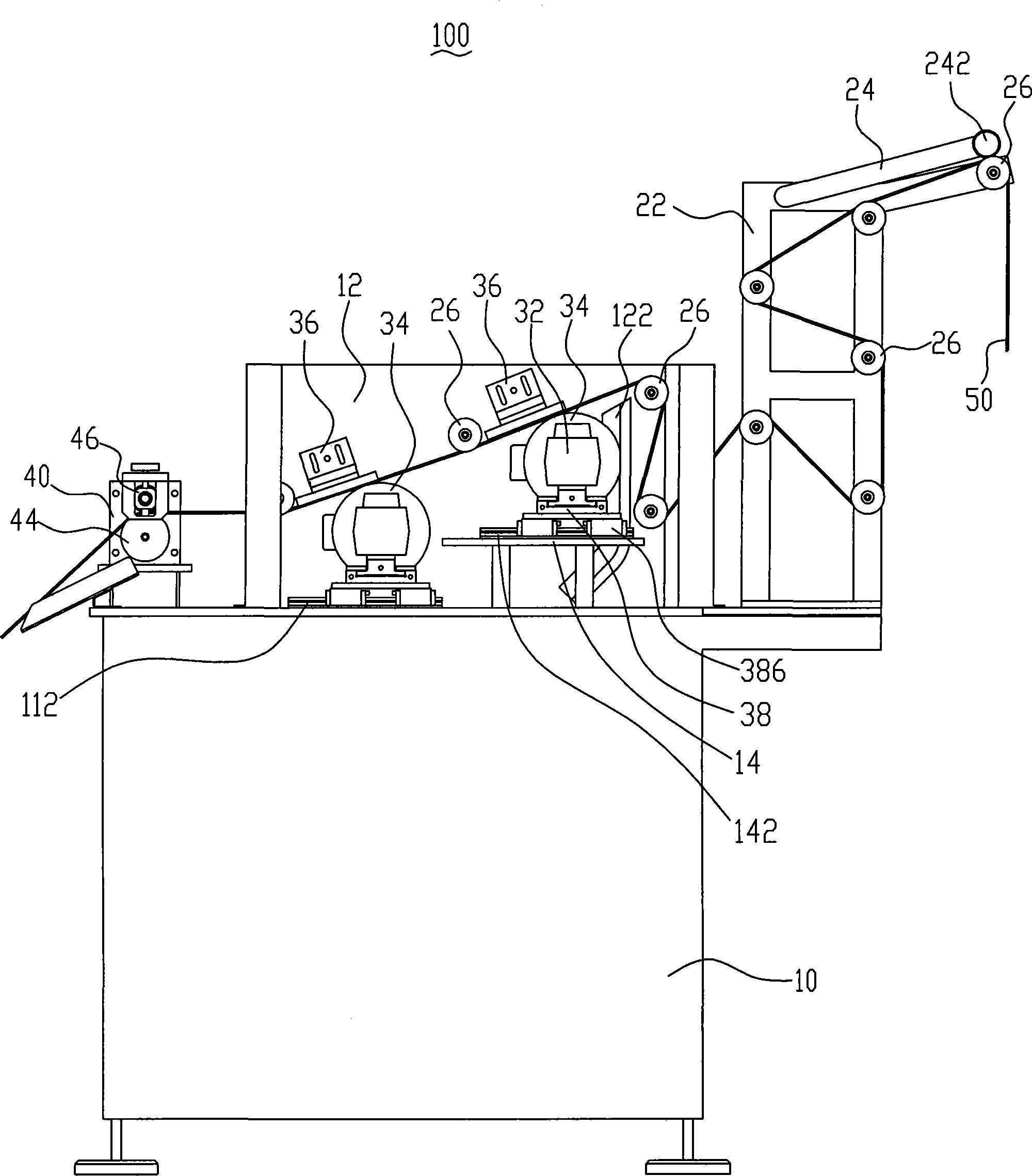

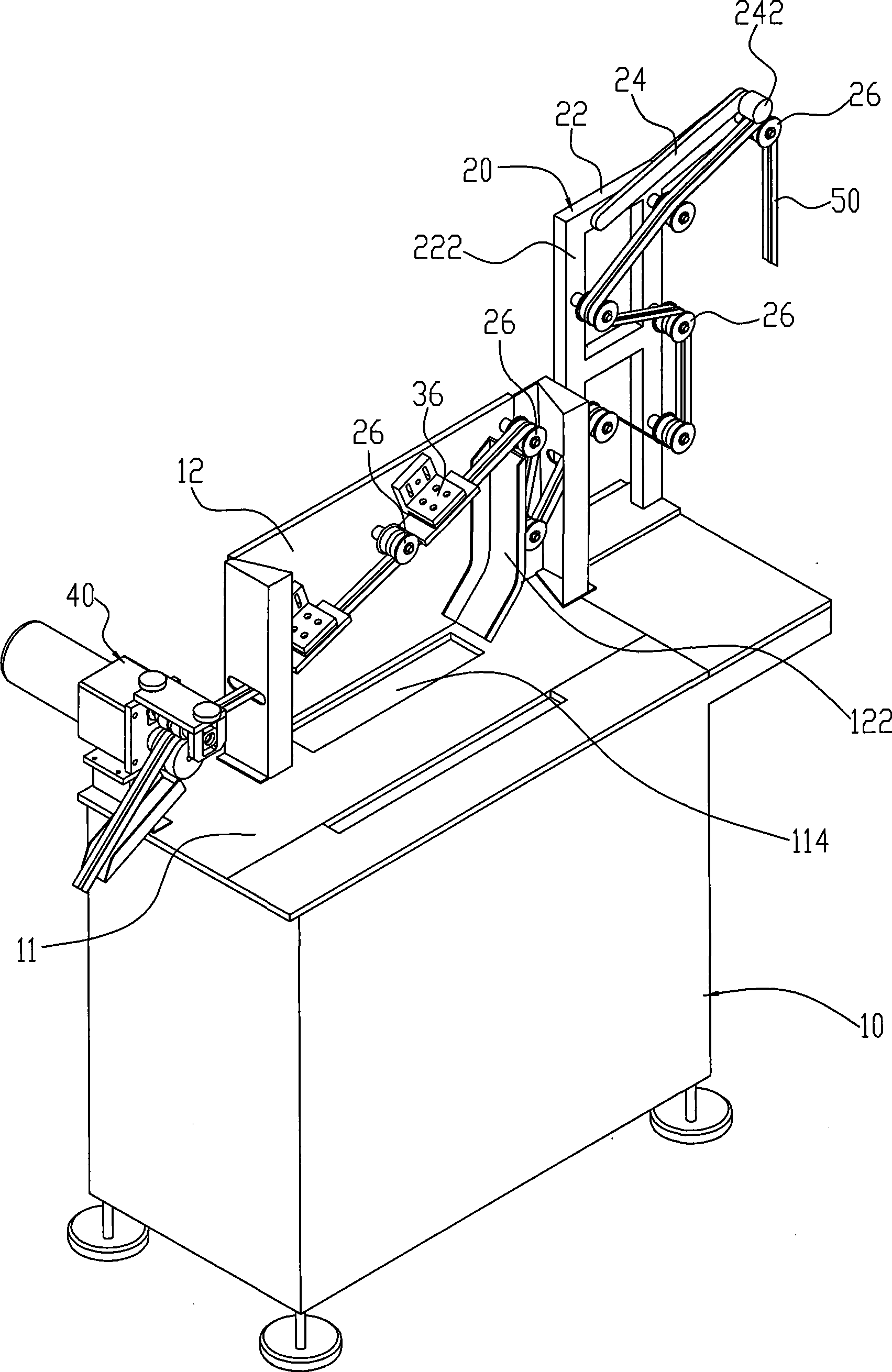

[0018] figure 1 Shown is a perspective view of the metal zipper surface processing equipment 100 according to the first embodiment of the present invention. The metal zipper surface processing equipment 100 includes a body 10 , a conveying mechanism 20 , two grinding mechanisms 30 , and a traction mechanism 40 . The metal zipper surface processing equipment 100 is used for surface grinding processing of the fastener elements of a metal zipper chain belt 50 . The chain belt 50 is formed by two unilateral chain belts embedded with metal chain elements and engaged with each other. Driven by the traction mechanism 40, the chain belt 50 passes through the two grinding mechanisms 30 successively through the guidance of the conveying mechanism 20, and the two grinding mechanisms 30 grind the chain element surfaces of the chain belt 50 moving in a straight line respectively. . Finally, the chain belt 50 after grinding is sent out of the metal zipper surface processing equipment 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com