A special-shaped gear transmission display device

A technology of display device and special-shaped gear, which is applied in the direction of hoisting device, portable lifting device, belt/chain/gear, etc., can solve the problem of single transmission mode, etc. The effect of good plastic workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

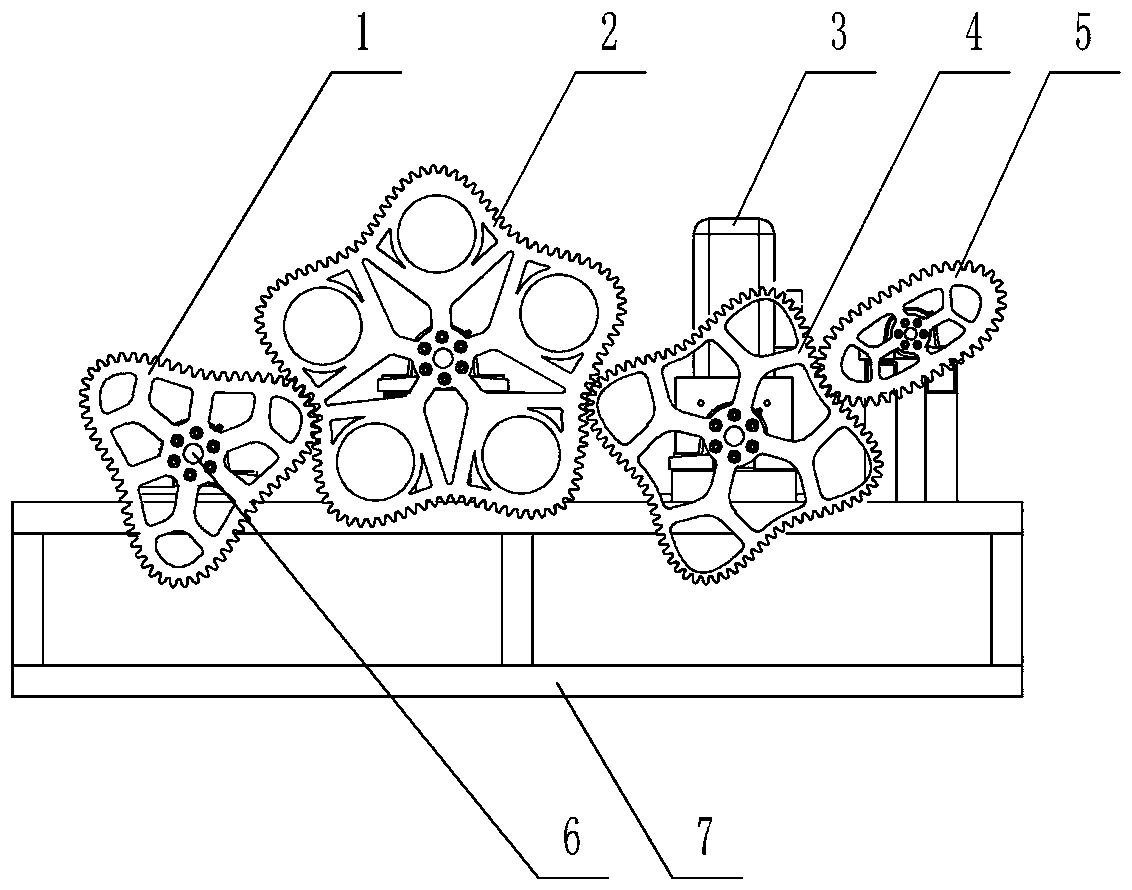

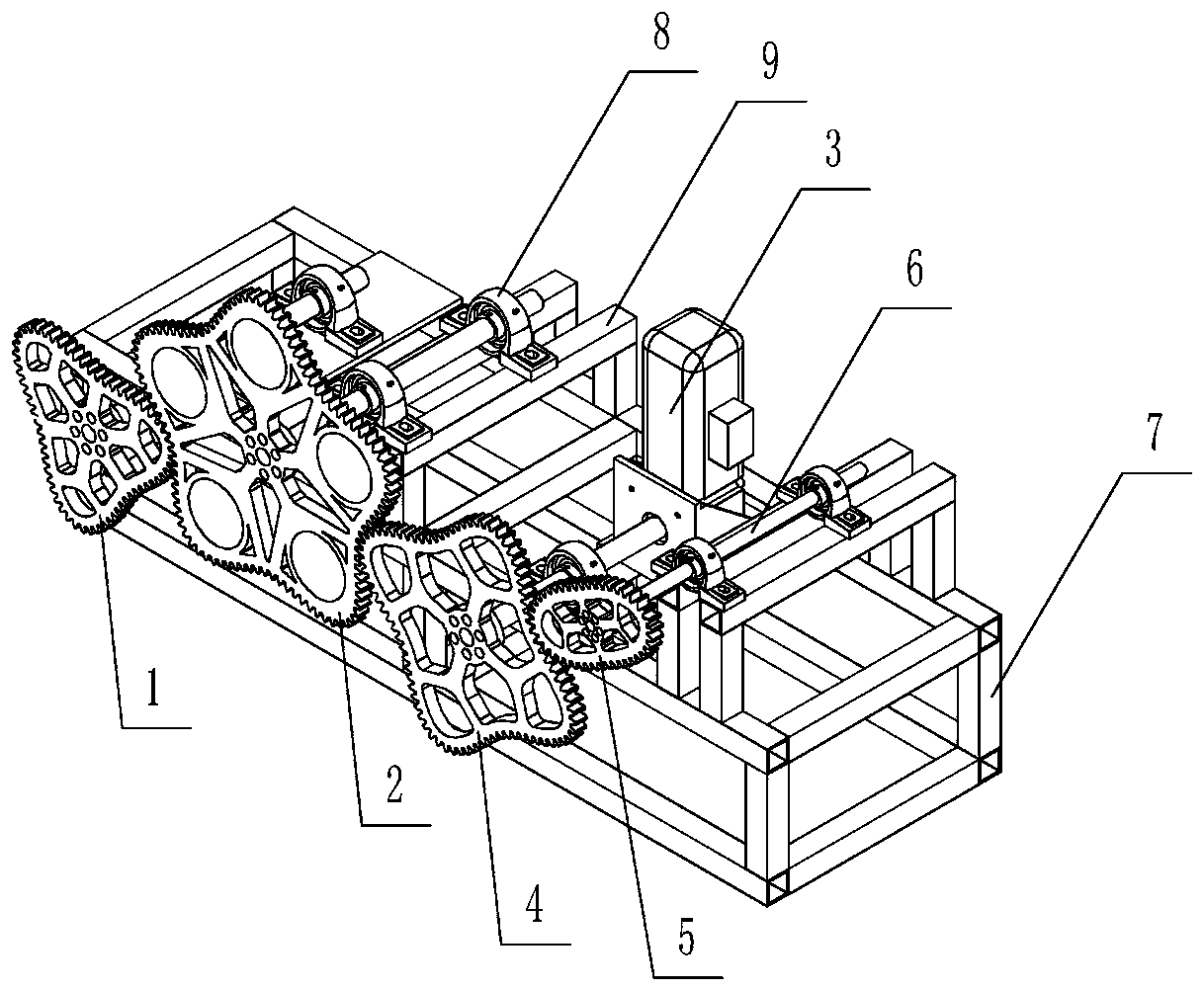

[0025] according to figure 1 with figure 2 , A special-shaped gear transmission display device, comprising a base 7; the base 7 is provided with multiple sets of brackets 9; the brackets 9 are respectively provided with a bearing seat 8 for mounting a central shaft 6, and one end of the central shaft 6 is A triangular gear 1, a five-pointed gear 2, a four-pointed gear 4, and an elliptical gear 5 meshing with each other are provided; the other end of any one of the central shafts 6 is drivingly connected with the motor.

[0026] The angles of the triangular gear 1, the pentagonal gear 2 and the quadrangular gear 4 are arcuate surfaces, and the edge line between the angles between the two arcuate surfaces is concave; the number of teeth on the arcuate surface and the concave surface is equal.

[0027] The triangular gear meshes with the pentagonal gear; the other side of the pentagonal gear meshes with the four-corner gear; the other side of the four-corner gear meshes with the oval...

Embodiment 2

[0032] A base and a support, the base and the support are an integrated structure, which is prepared according to the following process:

[0033] Step 1) Weigh each raw material in parts by weight for use: 100 parts magnesium, 20 parts aluminum, 5 parts copper, 5 parts silicon, 3 parts nickel, 2 parts molybdenum, 2 parts titanium, 1 part zirconium, 1 part zinc, 1 part vanadium Copies

[0034] Step 2) Take magnesium and heat it to 700°C under the protection of argon gas to obtain a magnesium melt;

[0035] Step 3) Take aluminum, copper, silicon, nickel, molybdenum, titanium, zirconium, zinc and vanadium, put them into a ball milling tank in turn, mix and ball mill for 12 hours to obtain powder;

[0036] Step 4) Start the resistance melting furnace, add the powder obtained in step 3) to the crucible, and pass N 2 As a protective gas, after the material to be added is completely melted, add the magnesium melt obtained in step 2), and continue to pass N 2 As a protective gas, stir for 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com