Zinc alloy

A zinc alloy, weight percentage technology, applied in the field of high-hardness zinc alloy metal abrasives, can solve the problems of poor plasticity and dimensional consistency, low hardness of casting structure, easy to break, etc., and achieve good cold plastic processing performance and intergranular corrosion The effect of small tendency and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in combination with specific embodiments.

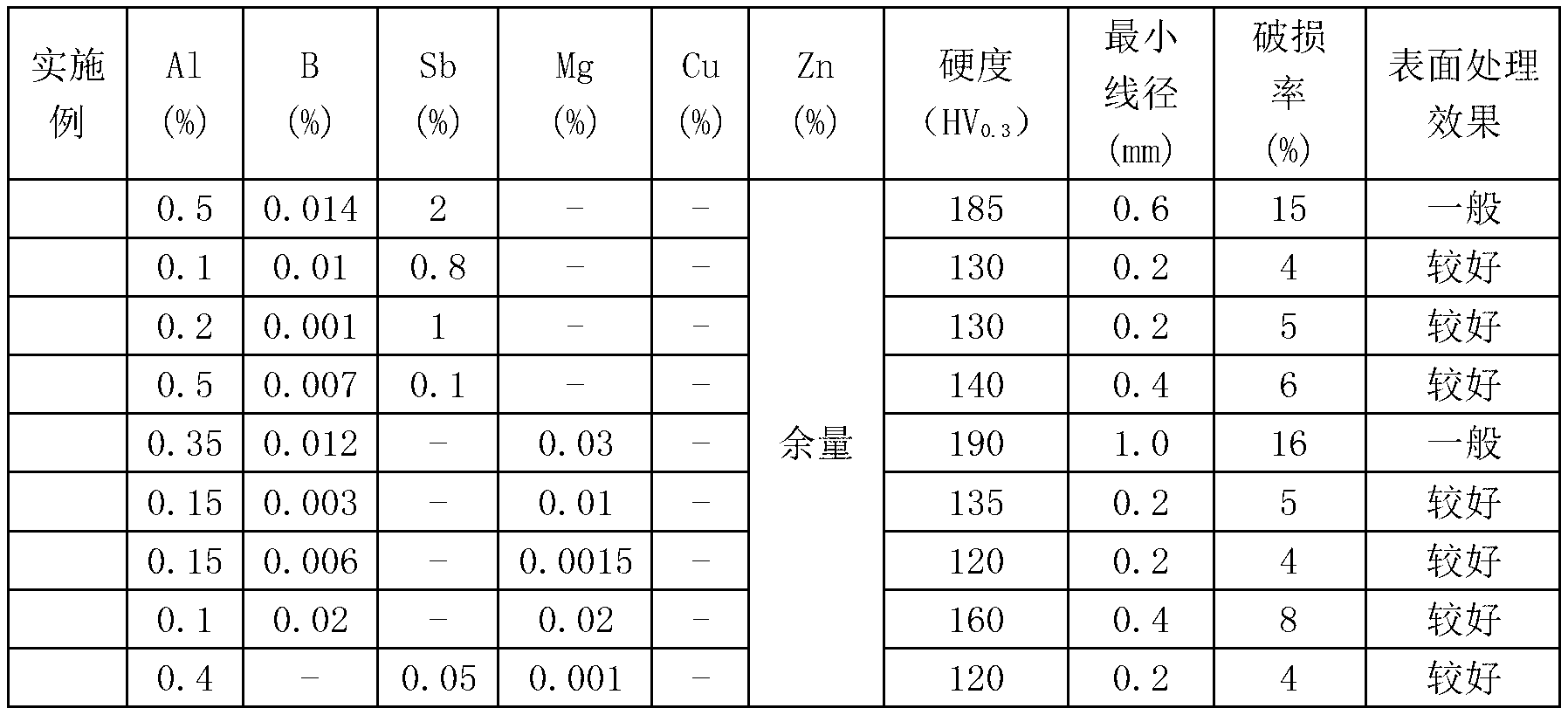

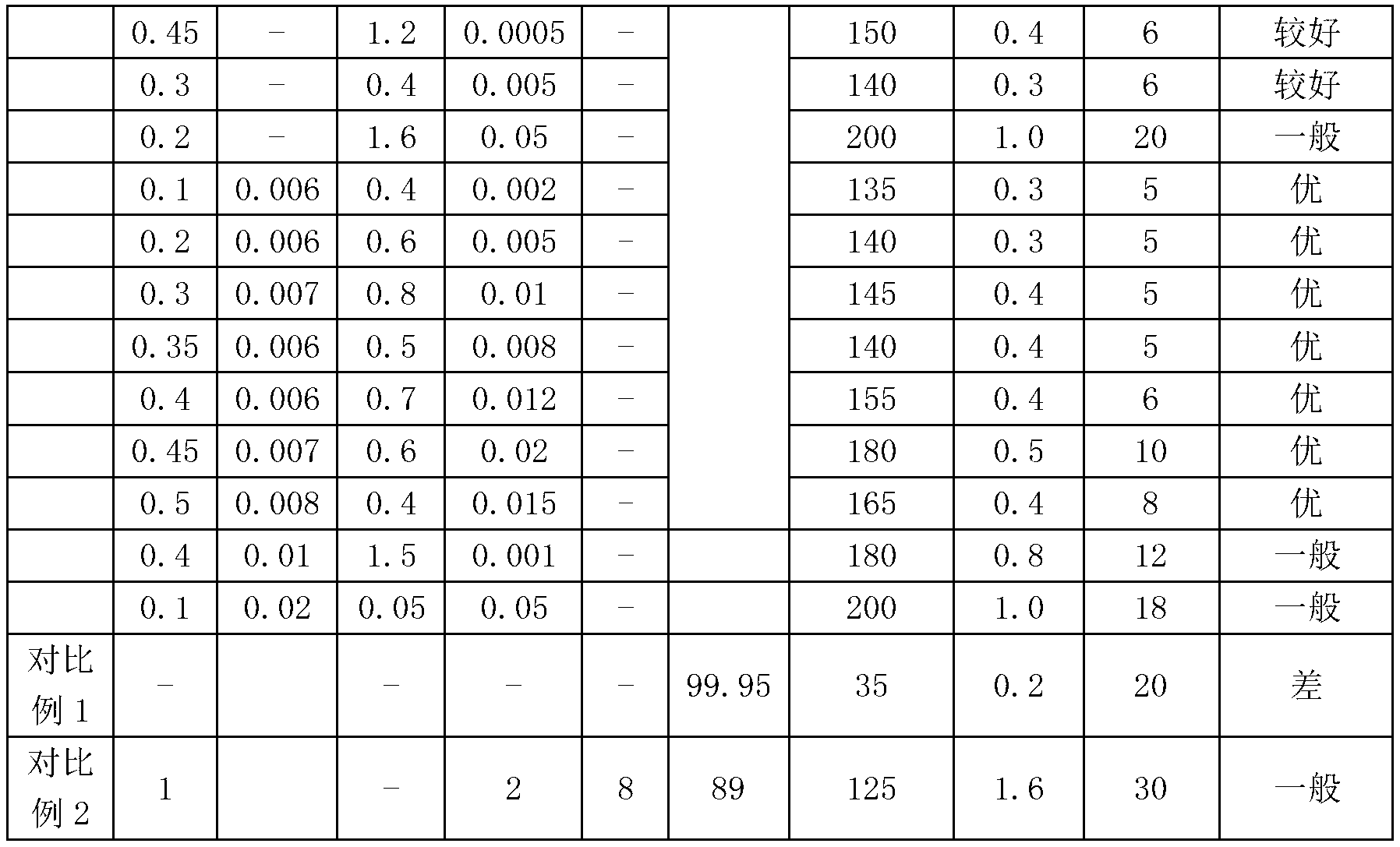

[0016] Concrete embodiment and comparative example are shown in table 1:

[0017] Table 1 specific embodiment and comparative example

[0018]

[0019]

[0020] Show by above-mentioned embodiment, with respect to the pure zinc metal abrasive material of comparative example 1, the hardness of the high-hardness zinc alloy metal abrasive material that can be drawn according to the present invention improves greatly, and breakage rate is low, and surface treatment effect is good; Compared with the cast zinc alloy metal abrasive of Comparative Example 2, the elongation rate of the high-hardness zinc alloy metal abrasive that can be drawn according to the present invention is greatly improved, and the breakage rate, minimum diameter and raw material cost are all greatly reduced. Note: Surface effect refers to the comprehensive effect of treatment time and surface burr remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com