Guide wheel system positioning spinning method

A guide wheel and guide technology, which is applied in the field of textile processing, can solve the problems of hard hand feeling of compact spinning, no effect of hemp fiber, easy to become hairiness, etc., achieve good evenness, improve spinning efficiency and yarn quality The effect of horizontal and whisker structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

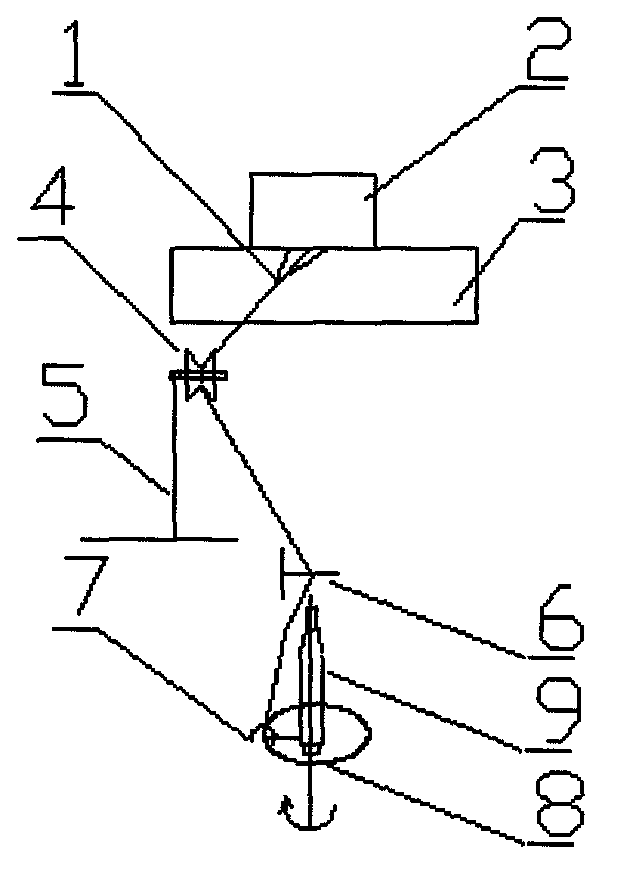

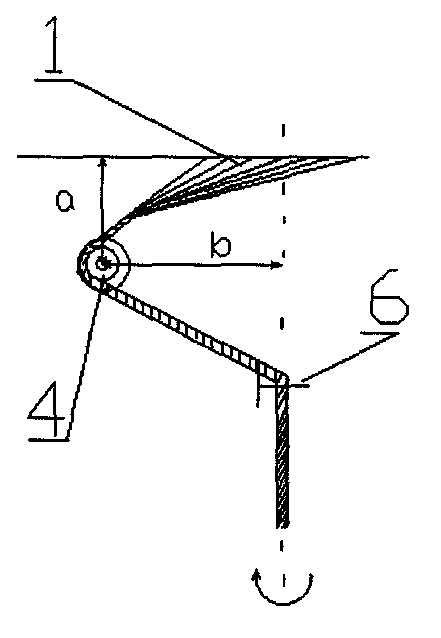

[0015] Install a guide wheel 4 in front of the front top roller 2 and front roller 3 of the ring spinning machine, the groove of the guide wheel 4 is V-shaped, and the bottom surface of the V-shaped groove of the guide wheel 4 is located on the common cutting surface of the front top roller 2 and front roller 3 In one side of the guide wheel 4, and the axis of the guide wheel 4 is perpendicular to the common tangential plane, after the strip 1 is output from the front nip formed by the front top roller 2 and the front roller 3, it is guided by the guide wheel 4, and then through the yarn guide hook 6, steel Collar 8 and steel traveler 7 are wound on the spun bobbin 9.

[0016] The vertical distance a from the axis of the guide wheel 4 to the front jaw line a≤20mm, and the vertical distance b≤30mm from the axis of the guide wheel 4 to the center point of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com