Novel colorful yarn on low-torque section, preparation method and preparation device thereof, fabric using the yarn

A low-torque, colored yarn technology, applied in fabrics, yarns, textiles, etc., can solve the problems of low-torque section colored yarn production technology records and applications, etc., to achieve rich layers and three-dimensional sense, soft and smooth feel, cost-effective high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

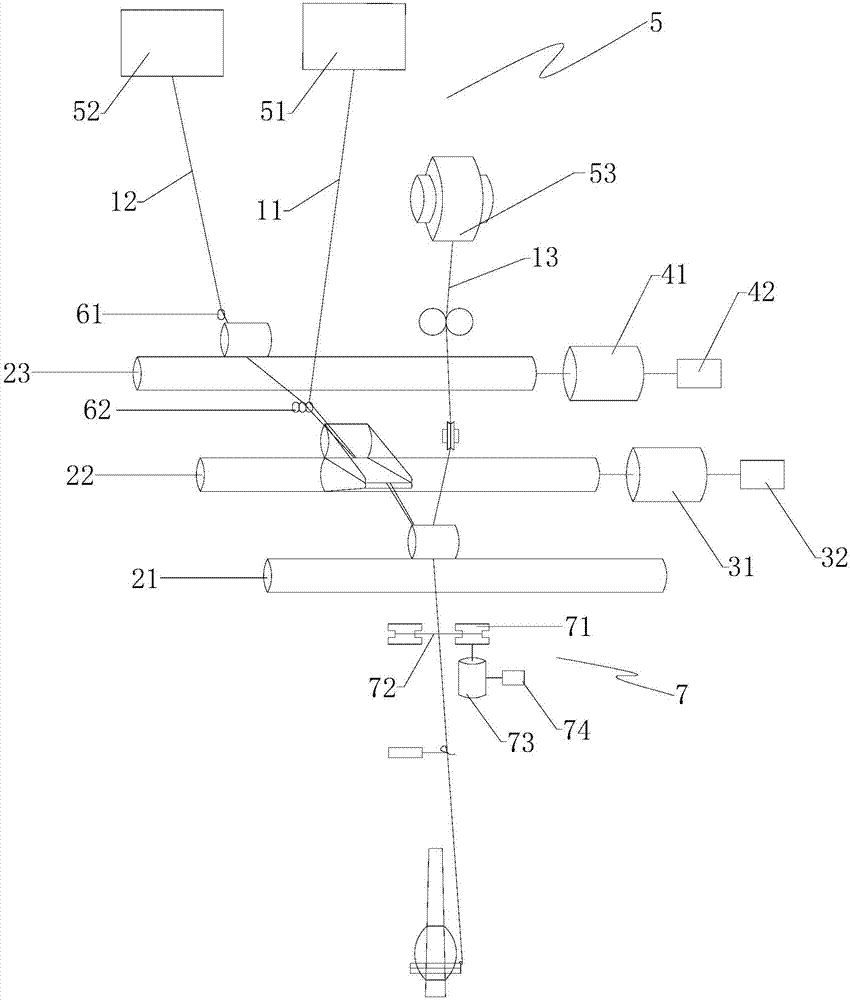

[0046] The working principle of the device of the present invention and the preparation method of the yarn are as follows:

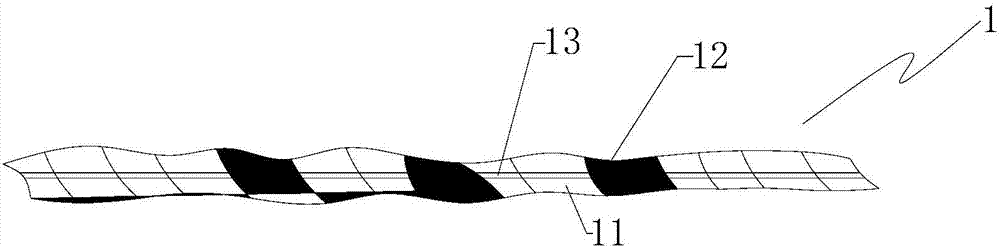

[0047]First, more than one group of basic fiber mustard rovings, colored fibers, and core-spun core yarns are installed on the raw material device 5; After the eye yarn guide 62, it is fed between the apron and the middle roller 22, and the colored fiber 12 is intermittently fed between the rear top roller and the rear roller 23 through the single eye yarn guide 61, passing through the multi-eye guide on the way. After the yarn device 62 is fed to the middle roller 22; the basic fiber strands 11 and the colored fibers 12 are respectively properly drawn, centered on the core-spun yarn 13, wrapped around each other, and then collected and twisted at the exit of the front roller 21 , Due to the false twist effect of the additional twist device, it is possible to obtain low residual torque into yarn and wind it into a yarn package (referred to as yarn). Dur...

Embodiment 1

[0051] Embodiment 1: warp yarn is Ne10 low-torque segment color yarn cotton yarn (colored fiber 10%, cotton fiber 90%), weft yarn is Ne16 pure cotton double-core yarn, cooperates to make 1 / 3 denim fabric, fabric weight reaches every square yard 11 oz. The surface of the fabric is smooth, less hairiness, soft and smooth to the touch. After the fabric is bleached, mercerized, dyed and finished, the color on the surface of the fabric shows a certain degree of irregular segmental distribution and unique style.

Embodiment 2

[0052] Embodiment 2: warp yarn is Ne7 low-torque section color yarn cotton yarn (colored fiber 10%, cotton fiber 90%), weft yarn is Ne10 pure cotton double-core yarn, cooperates to make 1 / 3 denim fabric, fabric weight reaches every square yard 14 oz. The surface of the fabric is smooth, less hairiness, soft and smooth to the touch. After the fabric is bleached, mercerized, dyed and finished, the color on the surface of the fabric shows a certain degree of irregular segmental distribution and unique style.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com