Oil Circuit Structure of Hydraulic Retarder and Its Method of Reducing No-load Loss

A hydraulic retarder and oil circuit technology, applied in the direction of hydraulic resistance brakes, brake components, brake types, etc., can solve the problem of high residual torque of the hydraulic retarder, improve overall performance, reduce weight, and improve use. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

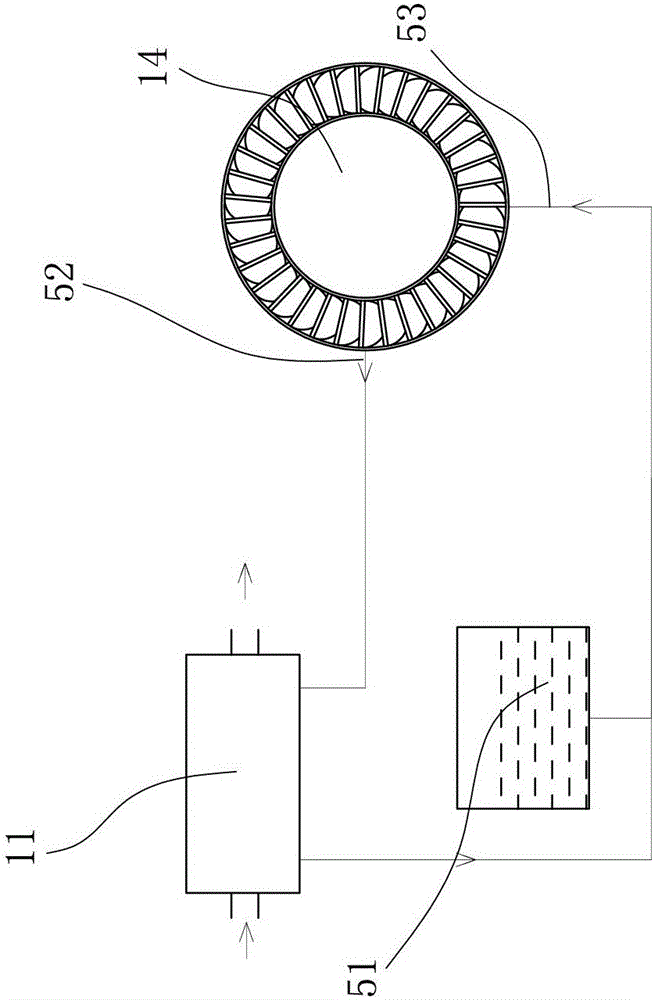

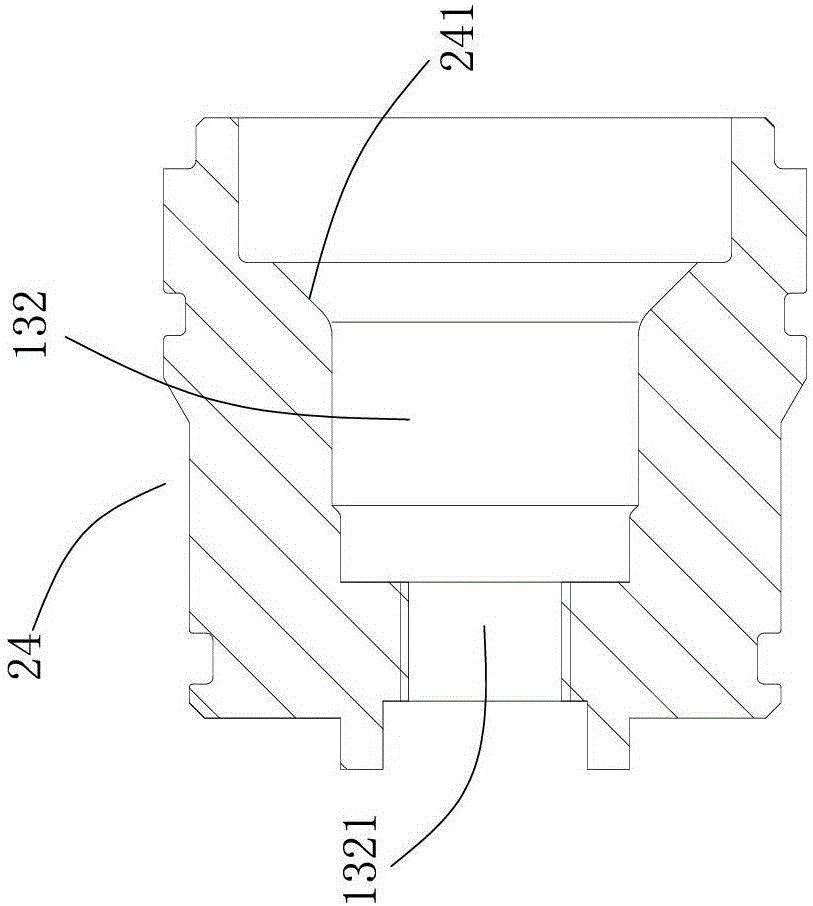

[0037] Example 1: figure 2 , image 3 and Figure 5 to Figure 12 The first embodiment of the present invention is shown, the oil passage structure of a hydraulic retarder of the present invention, which includes the oil passage structure formed by the sequential communication of the working chamber 14, the heat exchanger 11 and the oil tank 51, in which A bypass valve 2 is provided on the oil passage between the bypass port 13 of the working chamber 14 and the oil inlet 53 .

[0038] The bypass valve 2 includes an interlocking valve seat 24 and a valve cover 22, a valve core 23 is provided in a valve chamber 132 of the valve seat 24, and a bypass valve oil outlet hole 1321 is provided at one end of the valve chamber 132. The other end of the valve cavity 132 is provided with a sealing surface, and the sealing end 231 of the valve core 23 corresponds to the sealing surface. A spring 6 is arranged between at least one end of the valve cavity 132 and the sealing end 231 of the...

Embodiment 2

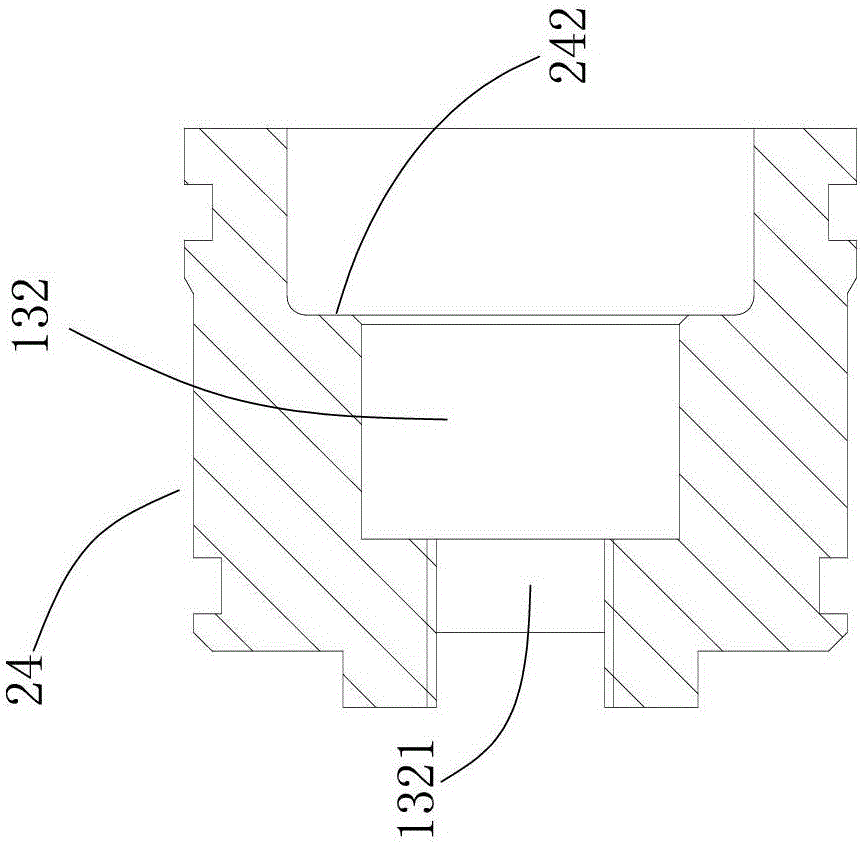

[0054] Example 2: figure 2 , Figure 4 Shows the second embodiment of the present invention, the oil passage structure of a hydraulic retarder of the present invention, which includes the oil passage structure formed by the sequential communication of the working chamber 14, the heat exchanger 11 and the oil tank 51, in which A bypass valve 2 is provided on the oil passage between the bypass port 13 of the working chamber 14 and the oil inlet 53 .

[0055] The bypass valve 2 includes an interlocking valve seat 24 and a valve cover 22, a valve core 23 is provided in a valve chamber 132 of the valve seat 24, and a bypass valve oil outlet hole 1321 is provided at one end of the valve chamber 132. The other end of the valve cavity 132 is provided with a sealing surface, and the sealing end 231 of the valve core 23 corresponds to the sealing surface. A spring 6 is arranged between at least one end of the valve cavity 132 and the sealing end 231 of the valve core 23. In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com