Device and method for preparing auxetic composite yarn with stable structure based on thermal fuse bonding

A technology of stable structure and thermal fusible filament, applied in the direction of yarn, spinning machine, drafting equipment, etc., can solve the problems of strong limitation of spinning method, unstable yarn structure, unsuitable for continuous production, etc., to improve structural stability The effect of stability and performance stability, simple spinning method and unique performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of spandex / thermal fuse (low melting point polyester) / nylon auxetic composite yarn

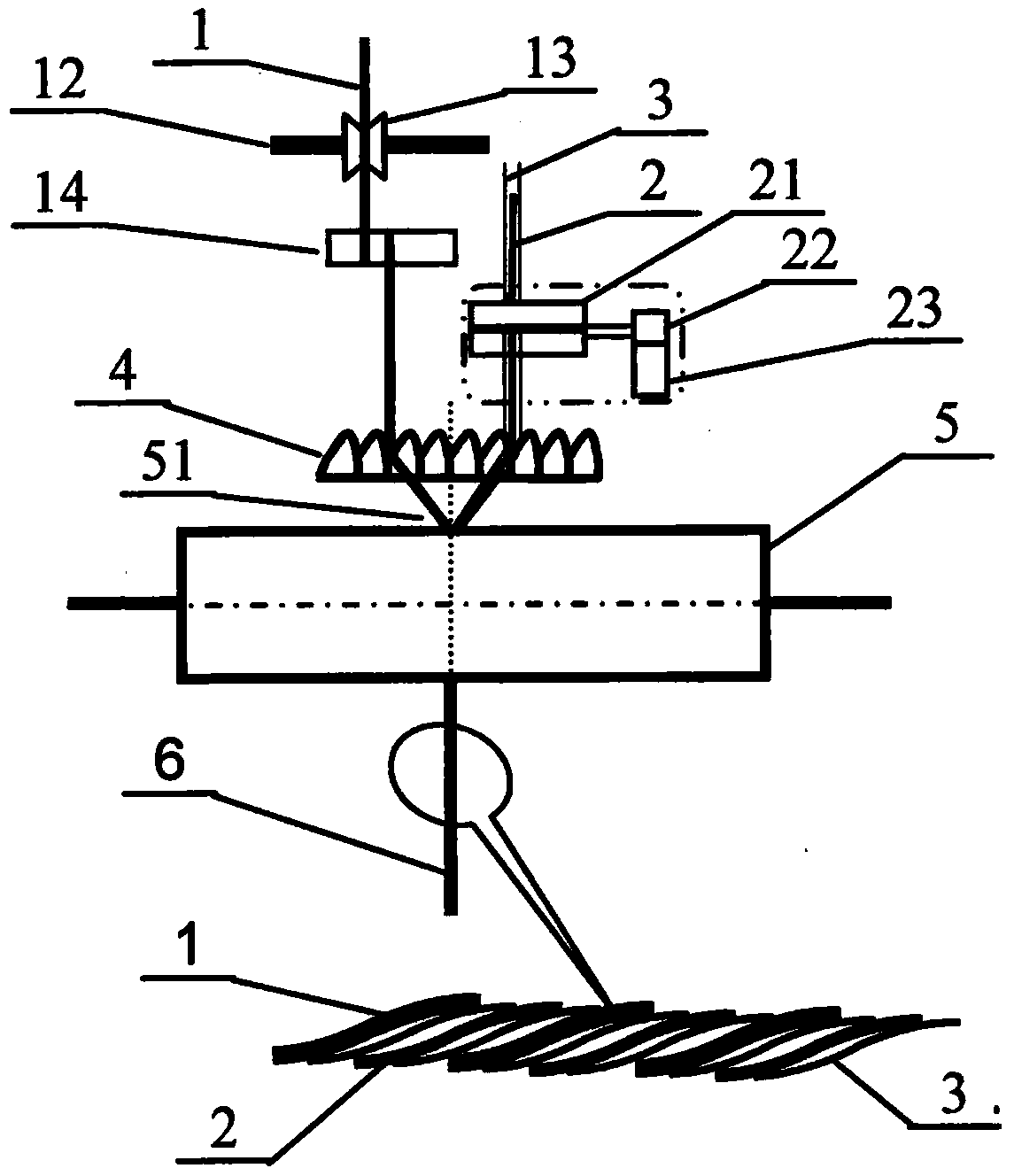

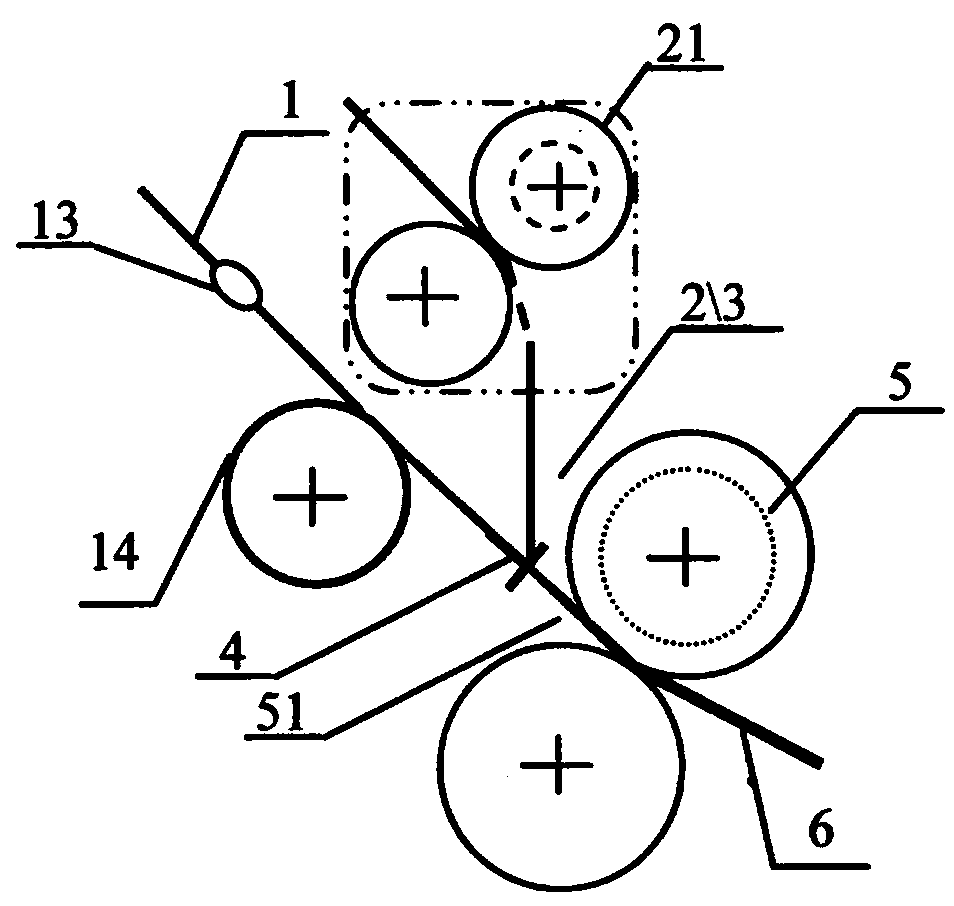

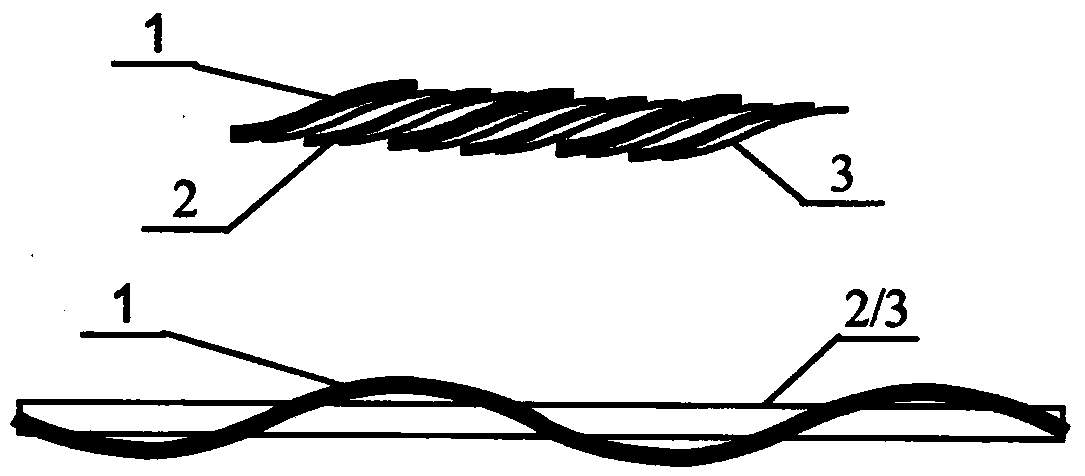

[0038] Such as figure 1 with figure 2 As shown, a device for preparing a stable structure auxetic composite yarn based on thermal fuse bonding, a multi-position yarn guide 4, can twist the rigid filament 2 and at least two thermal fuse 3 into untwisted, and The parallel of the elastic filament 1 and the rigid filament 2 and the thermal fuse 3 is fed to the yarn feeding and control mechanism of the converging twisting mechanism through the multi-position yarn guide 4 described above, and the elastic filament 1 and Convergent twisting mechanism for the parallel twisting of rigid filament 2 and thermal fuse 3 together.

[0039] The yarn feeding and control mechanism includes a tension plate 13 arranged on the yarn guide rod 12, a yarn guide roller 14, a holding roller pair 21, and a speed regulating roller 22. The elastic filament 1 passes through the tension plate 13 and...

Embodiment 2

[0045] Example 2 Preparation of spandex / thermal fuse (low melting point polyester) / ultra-high molecular weight polyethylene auxetic composite yarn

[0046] A method for preparing a stable structure auxetic composite yarn based on thermal fuse bonding, using the device for preparing a stable structure auxetic composite yarn based on thermal fuse bonding described in Example 1, respectively selecting spandex monofilament and ultra-high molecular weight Polyethylene is used as elastic filament 1 and rigid filament 2, and low-melting polyester is used as thermal fuse 3. The ultra-high molecular weight polyethylene and two low-melting polyester fibers are twist-free. The rest of the operation steps are the same as in Embodiment 1, and the description will not be repeated here. The oven treatment time is 45 minutes, and the temperature is set to 120°C. The specific process parameters are shown in Table 1.

[0047] In order to verify the innovative contribution of the present invention...

Embodiment 3

[0048] Example 3 Preparation of spandex / thermal fuse (low melting point nylon) / high-strength polyester yarn

[0049] A method for preparing a stable structure auxetic composite yarn based on thermal fuse bonding uses the device for preparing a stable structure auxetic composite yarn based on thermal fuse bonding described in Example 1, respectively selecting spandex monofilament and high-strength polyester filament As the elastic filament 1 and the rigid filament 2, low-melting nylon is used as the thermal fuse 3. The high-strength polyester yarn and two low-melting nylon yarns are twist-free. The rest of the operation steps are the same as in Embodiment 1, and the description will not be repeated here. The oven treatment time is 30 minutes, and the temperature is set to 110°C. The specific process parameters are shown in Table 1.

[0050] In order to verify the innovative contribution of the present invention, according to the ISO 3343-2010 international standard method, the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com