A stable structure auxetic composite yarn and its preparation device, method and application

A technology for preparing devices and stabilizing structures, applied in the field of spinning, can solve the problems of easy untwisting, difficult yarn, difficult spinning and weaving, etc., and achieve the effect of good forming, obvious auxetic effect and stable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 spandex / nylon auxetic composite yarn preparation

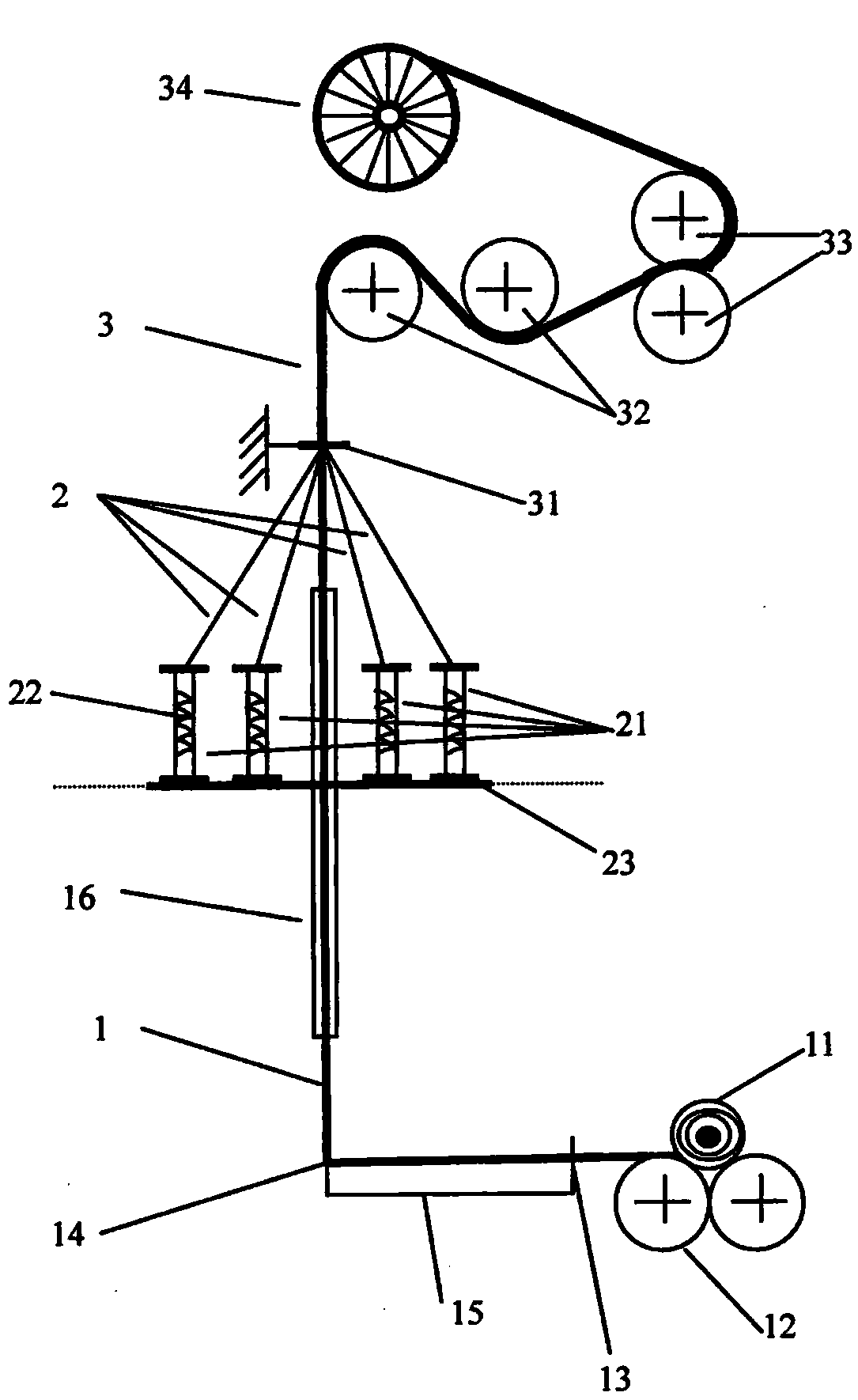

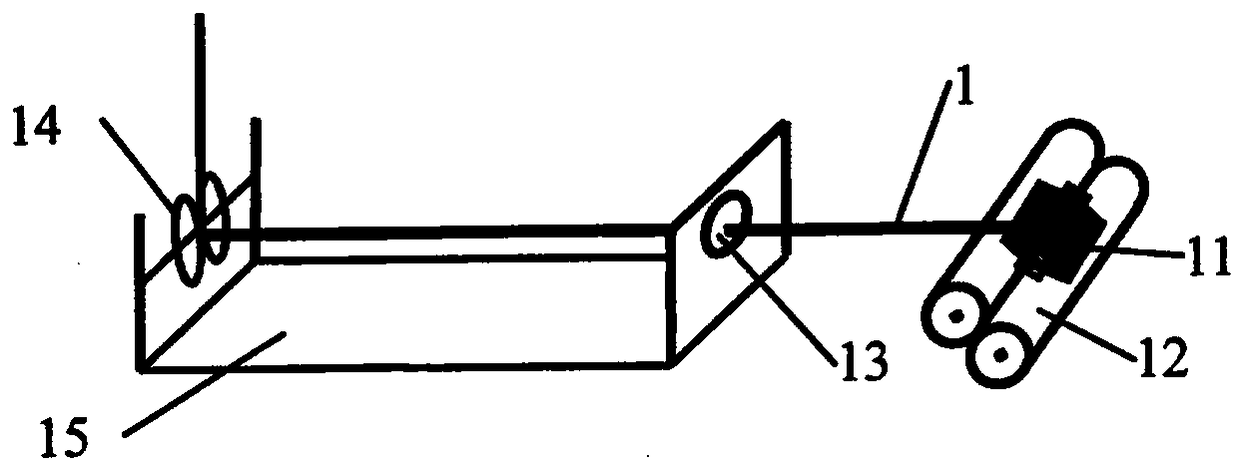

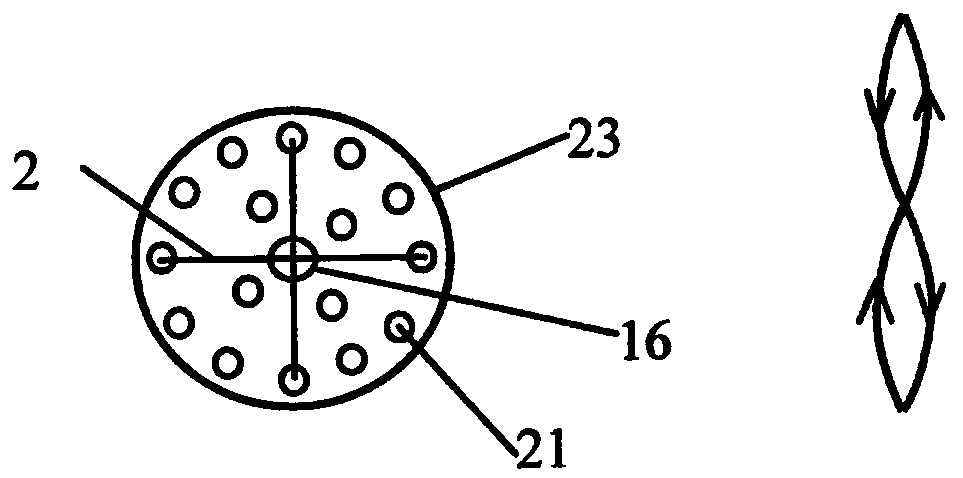

[0036] Such as figure 1 As shown, a device for preparing the above-mentioned auxetic composite yarn with stable structure includes a control structure capable of controlling yarn component feeding and a composite yarn forming and winding mechanism, and the yarn component feeding control structure includes a core Yarn feeding control mechanism and covered yarn feeding control mechanism; the core yarn feeding control mechanism includes a core yarn bobbin 11, a positive yarn feeding roller 12, a fixed frame 15 and a yarn guide tube 16, and the core yarn The bobbin 11 is placed on the active yarn feeding roller 12, the side of the fixed frame 15 close to the core yarn bobbin 11 is provided with a yarn guide hole 13, and the other side is provided with a tension disc 14, and the yarn guide tube 16 is arranged above the tension disc 14 ,Such as figure 2 As shown, the elastic core yarn 1 on the core yarn tube 1...

Embodiment 2

[0048] Example 2 Preparation of Spandex / UHMWPE Auxetic Composite Yarn

[0049] The preparation device described in Example 1 is used to spin the structurally stable auxetic composite yarn comprising multiple filaments, and one spandex filament and four ultra-high molecular weight polyethylene filaments are respectively selected as the elastic core yarn and covering Yarn, all the other operation steps are identical with embodiment 1, do not repeat description here. The specific process parameters are shown in Table 1.

[0050] Such as Figure 4 As shown, the obtained auxetic composite yarn with a stable structure includes a covering yarn 2 and an elastic core yarn 1, and the covering yarn 2 is cross-wrapped on the surface of the elastic core yarn 1, and has a negative Poisson's ratio effect.

[0051] In order to verify the innovative contribution of the present invention, according to the ISO 3343-2010 international standard method, implement the test of the curled length and...

Embodiment 3

[0052] Example 3 Preparation of spandex / high-strength polyester yarn auxetic composite yarn

[0053] Adopt the preparation device described in Example 1 to implement the spinning of the structurally stable auxetic composite yarn comprising multi-filaments, select 1 spandex and 2 high-strength polyester filaments as elastic core yarn and covering yarn respectively, and the remaining operation steps are the same as Embodiment 1 is the same and will not be repeated here. The specific process parameters are shown in Table 1.

[0054] Such as Figure 4 As shown, the obtained auxetic composite yarn with a stable structure includes a covering yarn 2 and an elastic core yarn 1, and the covering yarn 2 is cross-wrapped on the surface of the elastic core yarn 1, and has a negative Poisson's ratio effect.

[0055] In order to verify the innovative contribution of the present invention, according to the ISO 3343-2010 international standard method, the test of the curled length and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com