A damp heat twist fixing system

A technology of fixed twist and moist heat, which is applied in the direction of textiles and papermaking, can solve the problems of low airflow utilization efficiency and insufficient wetting effect, so as to facilitate the subsequent weaving process, improve the comprehensive quality of yarn and the added value of products, and realize The effect of yarn internal stress balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

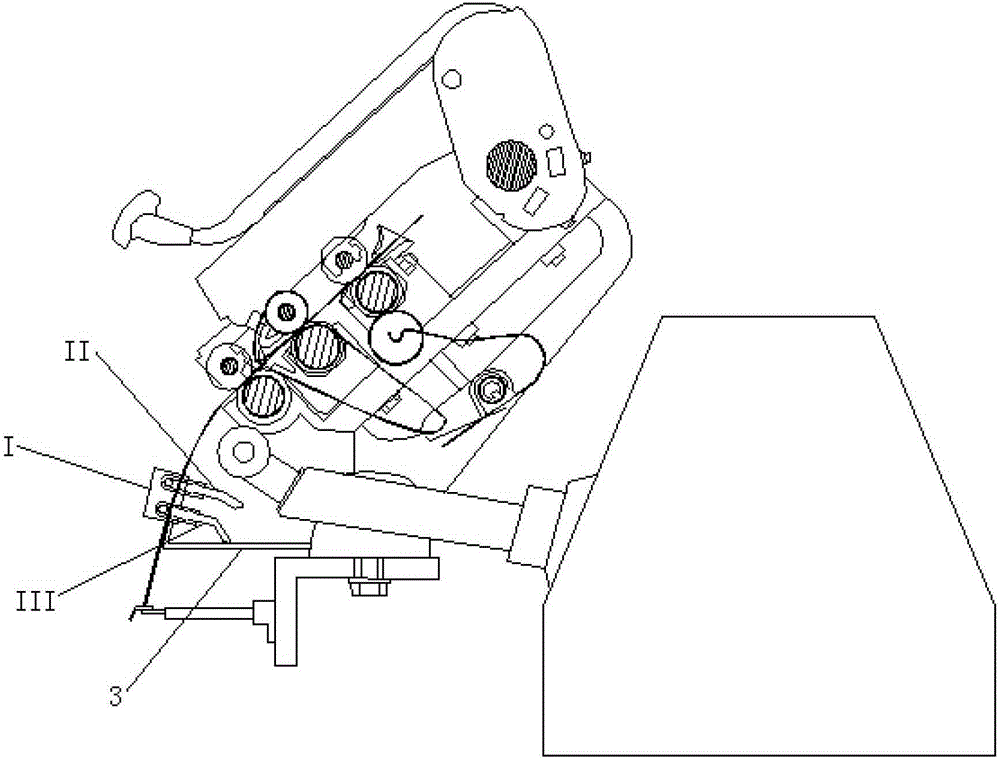

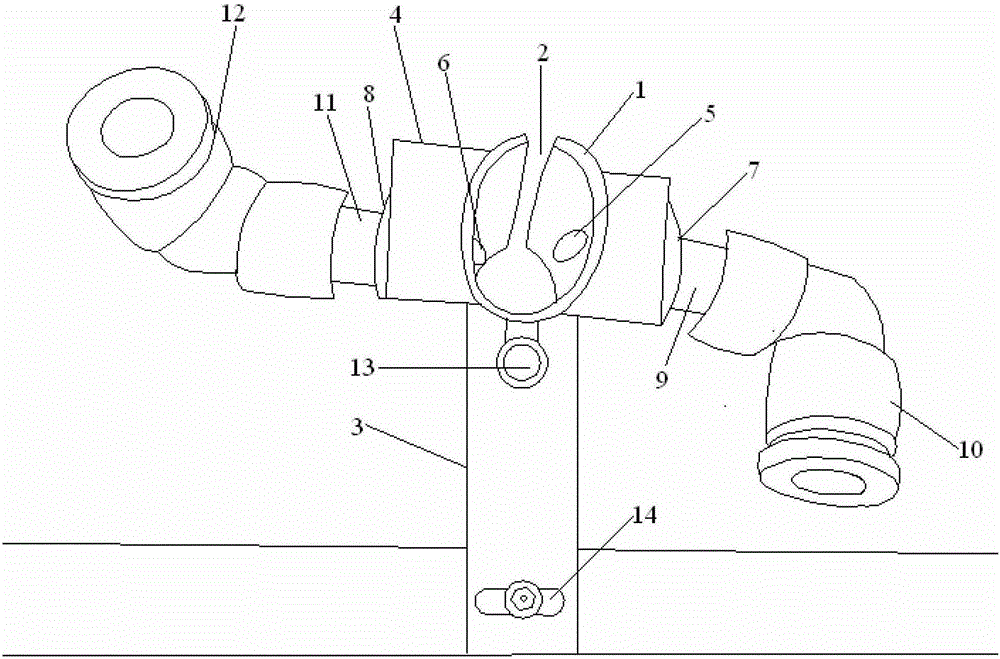

[0012] like figure 1 and 2 As shown, the wet heat twist fixing system 1 of the present invention comprises a cylindrical hollow passage 1 made of ceramic material, the length of the hollow passage 1 is 25mm, the radius is 5mm, a slit 2 is arranged at the front end of the hollow passage 1, and the rear end of the hollow passage 1 is It is connected with the bracket 3 made of material with good heat conduction function, the bracket 3 is fixed in the oval hole 14 on the vehicle surface of the spinning frame by screws, and the end of the bracket 3 connected with the vehicle platform is equipped with a heating element with adjustable temperature. Device 13, the hollow channel 1 is covered with a layer of heat insulating material 4 except for the arc-shaped gap part 2, and the cylindrical hollow channel 1 contains the air inlet system II and the air outlet system III, and there is a radius on the left side of the upper end of the hollow channel 8mm A circular hole 6 with a diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com