Cotton and hemp blended yarn based imitation pure hemp yarn and spinning method thereof

A technology for blending yarn and cotton and linen, applied in the textile field, can solve the problems of complicated operation and high production cost, and achieve the effects of improving yarn strength, reducing yarn cost and reducing yarn breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

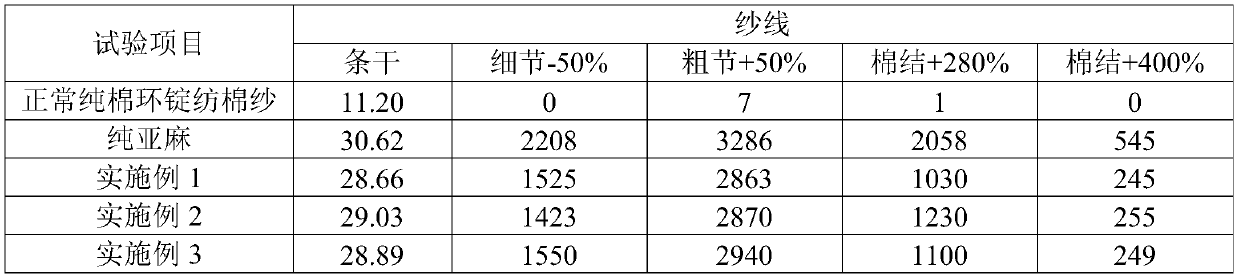

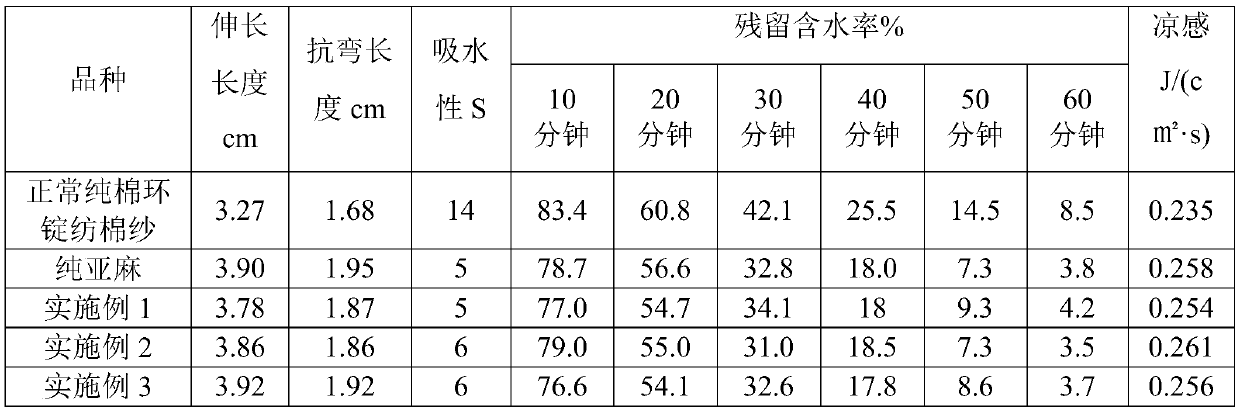

Embodiment 1

[0031] The cotton-linen blended yarn described in the present embodiment 1 imitates pure linen yarn, and is made up of following raw material:

[0032] Fine cotton card noil 50%

[0033] Fine Staple Cotton 45%

[0034] Linen Loose Fiber 5%.

[0035] The spinning method of imitating pure linen yarn of the cotton-linen blended yarn described in the present embodiment 1 is prepared by the following steps:

[0036] (1) 50% of fine-staple cotton carding noil, 45% of fine-staple cotton and 5% flax loose fibers are opened by a comb-hand opening method to obtain opened fluffy short fibers.

[0037] (2) the fluffy short fiber prepared in the step (1) is made into a roving with a quantitative value of 6.0g / 10m and a twist coefficient of 125 through the carding process→drawing process→roving process; the cover plate in the carding machine The five-point gauge to the cylinder is 14-12-12-12-12; the cylinder speed is 360r / min, and the licker-in roller speed is 810r / min. The drawing pro...

Embodiment 2

[0041] The cotton-linen blended yarn described in the present embodiment 2 imitates pure linen yarn, and is made up of following raw materials:

[0042] Fine-staple cotton card noil 60%

[0043] Fine Staple Cotton 33%

[0044] Linen Loose Fiber 7%.

[0045] The spinning method of imitating pure linen yarn of the cotton-linen blended yarn described in the present embodiment 2 is prepared by the following steps:

[0046] (1) 60% fine-staple cotton carding noil, 33% fine-staple cotton and 7% flax loose fibers are opened by a comb-hand opening method to obtain opened fluffy short fibers.

[0047] (2) the fluffy short fiber prepared in the step (1) is made into a roving with a quantification of 6.0g / 10m and a twist coefficient of 130 through the carding process→drawing process→roving process; the middle cover of the carding machine The five-point distance between the board and the cylinder is 16-14-14-14-14; the cylinder speed is 360r / min, and the licker-in roller speed is 810r / ...

Embodiment 3

[0051] The cotton-linen blended yarn described in the present embodiment 3 imitates pure linen yarn, and is made up of following raw materials:

[0052] Fine Staple Cotton Card Noil 45%

[0053] Fine Staple Cotton 45%

[0054] Linen Loose Fiber 10%.

[0055] The spinning method of imitating pure linen yarn of the cotton-linen blended yarn described in the present embodiment 3 is prepared by the following steps:

[0056] (1) 45% of fine-staple cotton carding noil, 45% of fine-staple cotton and 10% flax loose fiber are opened by the way of card needle beater opening to obtain opened fluffy short fibers.

[0057] (2) the fluffy short fiber prepared in the step (1) is made into a roving with a quantitative value of 6.0g / 10m and a twist coefficient of 135 through the carding process→drawing process→roving process; the cover plate in the carding machine The five-point gauge to the cylinder is 16-14-14-14-14; the cylinder speed is 330r / min, and the licker-in roller speed is 760r / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com