A kind of slub yarn and its production method

A production method and technology of slub yarn, applied in the direction of yarn, textile and papermaking, can solve the problems of high price, complex structure, low customer acceptance, etc., and achieve the effect of high added value and low yarn cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

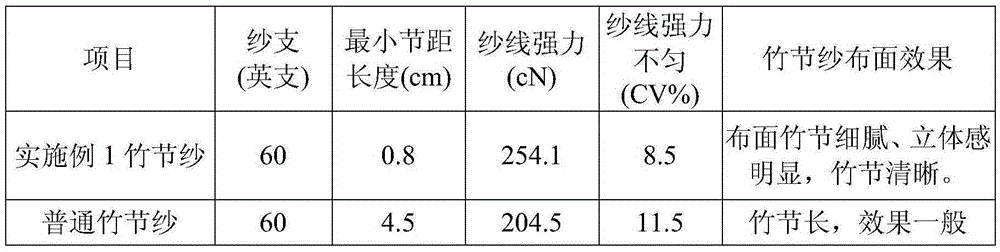

Examples

Embodiment 1

[0030] This embodiment provides a low-cost and high-value-added slub yarn, the production method of which comprises the following steps: cotton preparation, sliver preparation, drawing, roving, spun yarn and winding;

[0031] Wherein, the cotton distribution preparation includes: grabbing the long-staple cotton A and the combed noil B of the long-staple cotton separately by the plucking machine, using the long-staple cotton A and the combed noil B of the long-staple cotton as raw materials, and The amount of neps of the combed noil B of the long-staple cotton is 480 grains / gram, and the short fiber (<0.5 inch) content is 40% (based on the total weight of the combed noil B), above The quarter length (weight ratio) is 20mm, and the length of 25mm accounts for about 4.5% (based on the total weight of the combed noil B);

[0032]The preparation of the sliver includes: carding the combed noil B through a carding machine to make a special sliver C, making the long-staple cotton A go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com