Method for producing extra high count compact spinning yarn by using superfine denier tencel fiber

A technology of Tencel fiber and manufacturing process, which is applied in the field of weaving technology of textile products, and can solve the problems of high short pile, many color and grain defects on the cloth surface, and difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

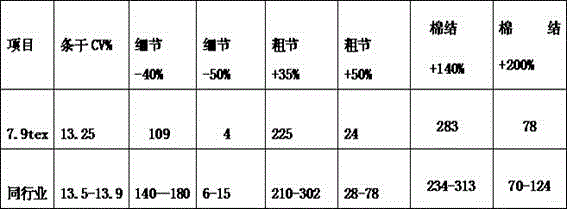

[0015] The invention uses ultra-fine tencel fibers with a fineness of ≤1.0dtex and a length of 38mm. The raw materials are pretreated to eliminate static electricity and humidify. Short staple: Rieter autoleveler drawframe is used for drawing frame, and compact spinning equipment is used for spun yarn to ensure uniform yarn dryness, less hairiness, high strength and less defects, suitable for the production of high-end fashion fabrics.

[0016] The superfine denier tencel fiber produced by the process of the present invention is used to produce ultra-high-count compact spinning yarns of more than 70 counts, and the cotton spinning equipment adopted has no new equipment except the compact spinning device added to the traditional spinning frame. Various parameters in each process can be selected according to the yarn count. If the yarn count is low, select the parameter with a correspondingly large weight and high speed; if the yarn count is high, select the parameter with a corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com