Spinning process of waterless colored heather yarns

a technology of colored heather yarn and spinning process, which is applied in the direction of yarn, dye addition to spinning solution, melt spinning method, etc., can solve the problems of process that is still not as environmentally friendly, process that requires high energy, water and electricity, etc., and achieves enhanced color effects, enhanced yarn strength, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

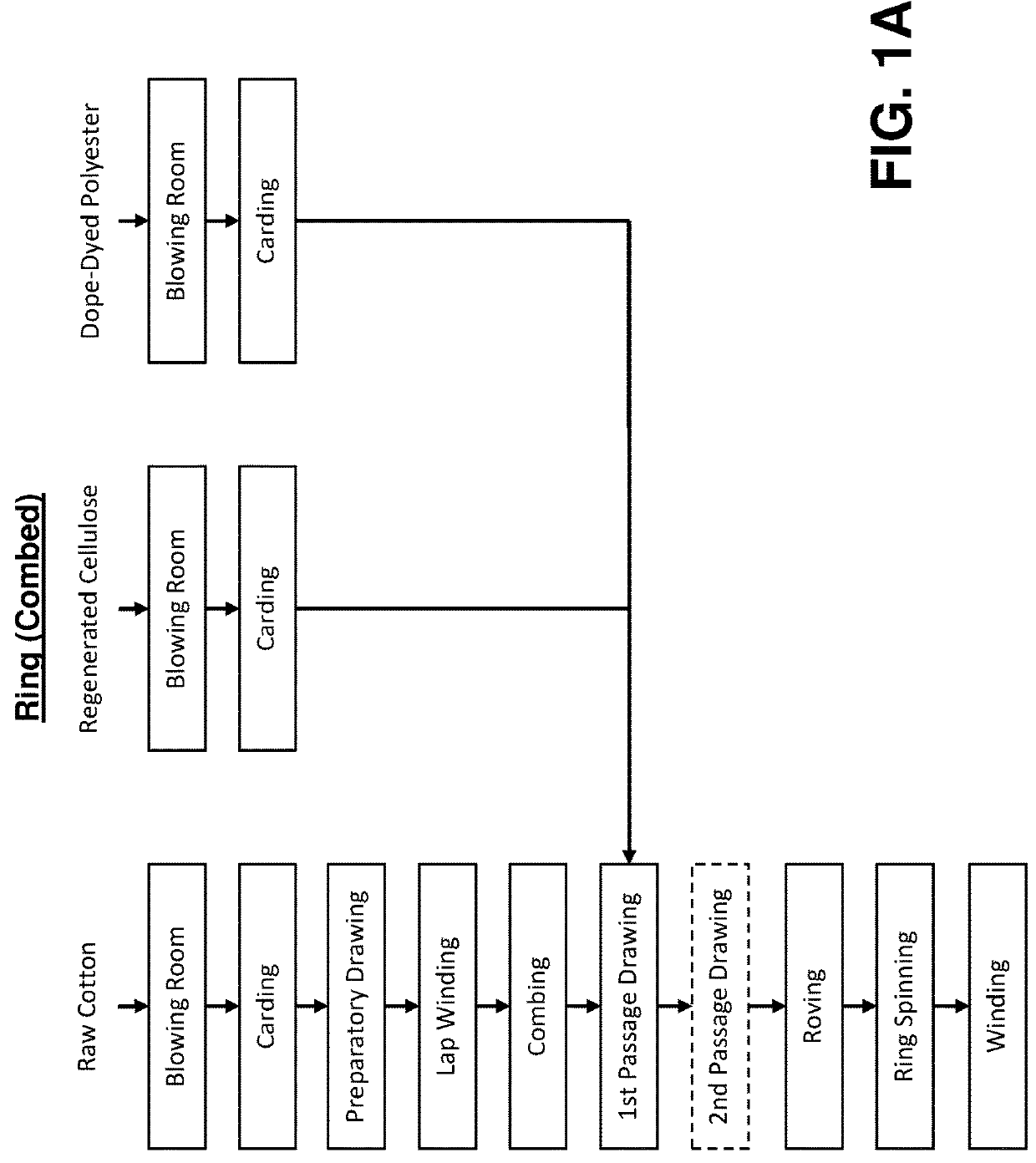

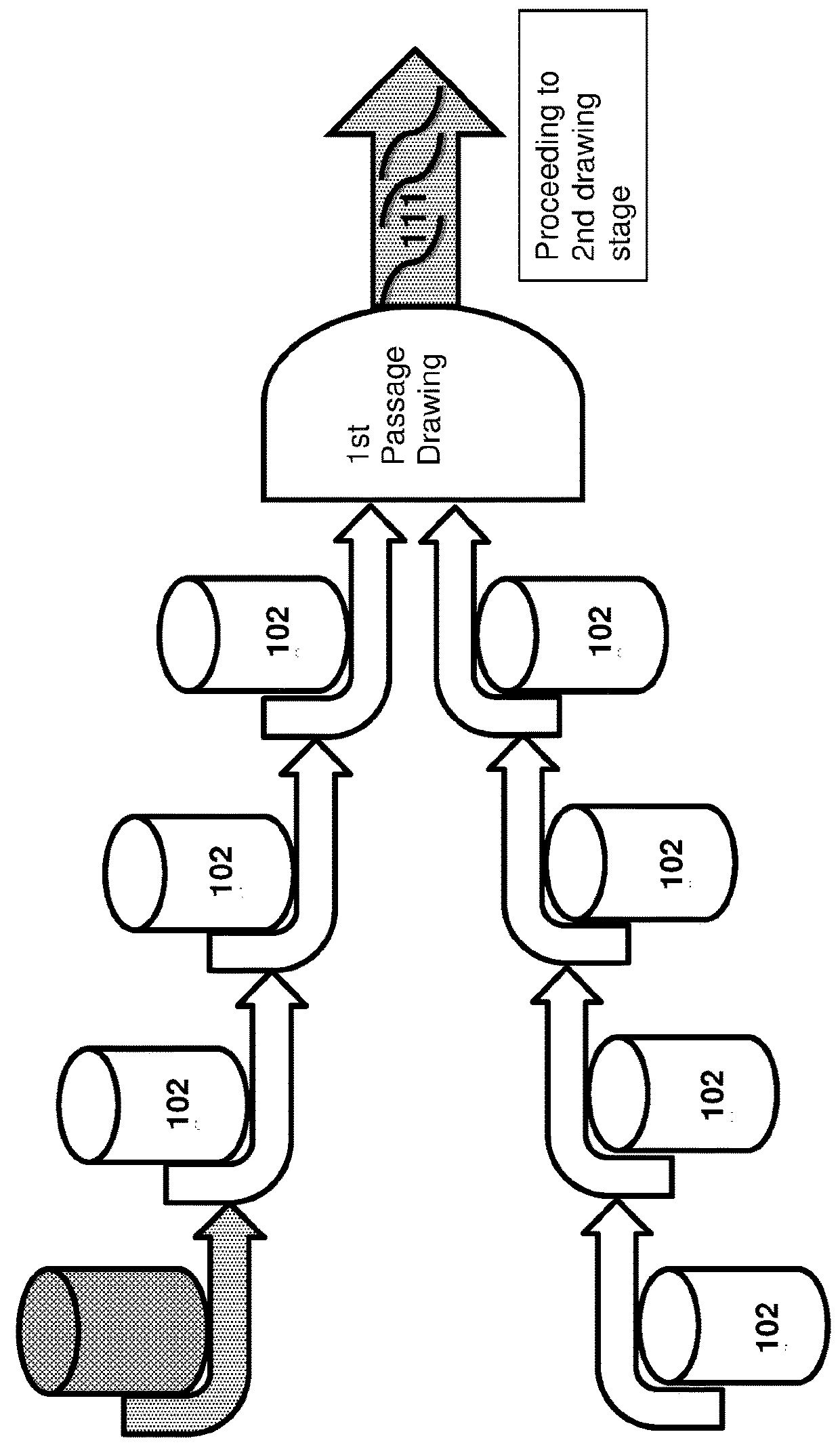

[0059]As demonstrated in FIG. 1A, raw cotton staple fibers undergo the blowing room process to be cleaned up, and the carding process where the fibers are further cleaned up and separated. The cotton slivers are then subjected to the drawing process to improve uniformity, and finally the combing process to remove the final proportion of short fibers, neps and other impurities. At this point, the raw cotton staple fibers (55%-95%) are ready for the first passage drawing with the regenerated cellulose sliver fiber (2%-25%) and the dope-dyed polyester sliver fiber (3-20%) having a staple length of 38 mm at 1.5 Denier as shown in FIG. 1A. The polyester sliver fiber is prepared using waterless colored polyester chips heated to a molten state, and spun in the molten polyester chips into the desired staple length colored fiber. To ensure a proper fiber content ratio (55 / 45-95 / 5) during the first passage drawing stage, one dope-dyed polyester colored sliver (101) is fed ...

example 2

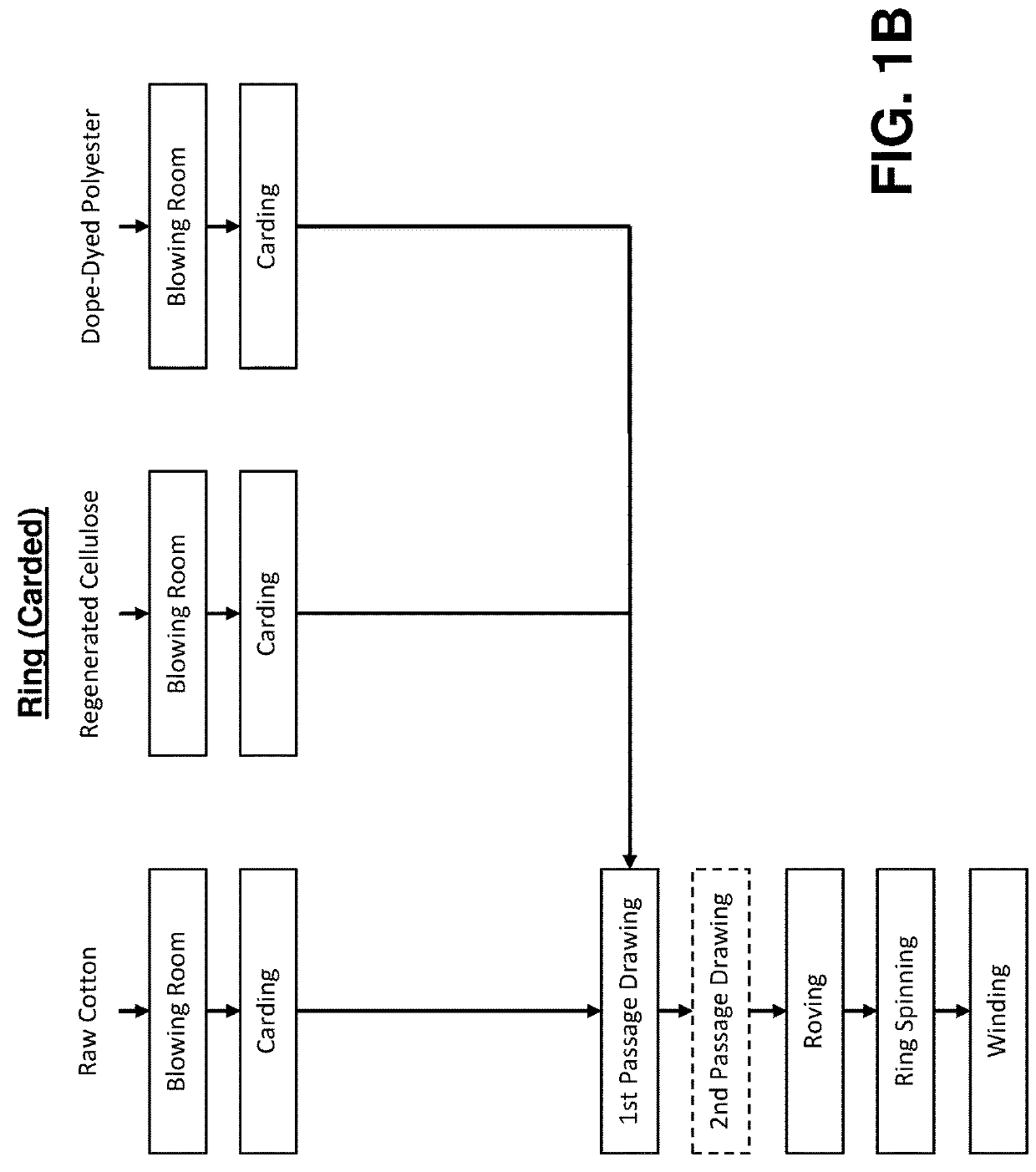

[0060]As demonstrated in Example 1 and FIG. 1B, similarly, the raw cotton staple fibers undergo the blowing room process to be cleaned up, and the fibers are further cleaned up and separated during the carding process. At this point, the raw cotton staple fibers (55%-95%) are ready for the first passage drawing with the regenerated cellulose sliver fiber (2%-25%) and the dope-dyed polyester sliver fiber (3-20%) having a staple length of 38 mm at 1.5 Denier as shown in FIG. 1B. The polyester sliver fiber is prepared using waterless colored polyester chips, heated to a molten state, and spun in the molten polyester chips into the desired staple length fiber. To ensure a proper fiber content ratio (55 / 45-95 / 5) during the first passage drawing stage, one dope-dyed polyester colored sliver (101) is fed with seven raw slivers (102), containing raw cotton sliver fibers, raw regenerated cellulose sliver fibers, or both, to form the first blended fiber having a 12.5% colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com