Warp knitted fabric containing cotton and processing method for warp knitted fabric

A fabric and warp knitting technology, which is applied to cotton-containing warp knitted fabrics and their processing fields, can solve the problems of mercerized yarns such as hard hand feeling, contamination with dust, blocking of needle holes, etc., and achieves improved softness and smoothness performance, high evenness uniformity , the effect of strong lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A cotton-containing warp-knitted fabric is a printed cotton-containing warp-knitted fabric, which is warp-knitted from top yarn, middle yarn and bottom yarn. The above-mentioned top yarn is 33.3dtex polyester filament, and the above-mentioned middle yarn is 100% 300S / 2 Egyptian long-staple cotton yarn, the above-mentioned base yarn is 22.2dtex spandex elastic yarn, and the above-mentioned Egyptian long-staple cotton yarn is processed by the following processing steps:

[0049] (1) Spinning, select 100% Egyptian long-staple cotton with an average length greater than 35mm, and perform compact spinning on it to obtain a cotton yarn with a count of 300S / 2;

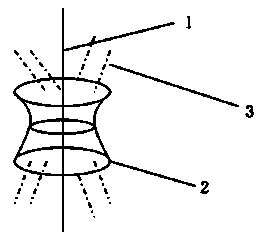

[0050] (2) For singeing, the hairiness on the surface of the cotton yarn obtained in step (1) is uniformly removed by using the ring burner 2 at 1500°C. The ring burner 2 is set as a cylindrical structure with openings at both ends. Burner flame 3 on the inner wall of described cylindrical structure, cotton yarn 1 pass...

Embodiment 2

[0073] A cotton-containing warp-knitted fabric, which is a two-color cotton-containing warp-knitted fabric, is formed by warp-knitting top yarn, middle yarn and bottom yarn, the above-mentioned top yarn is 222dtex polyester filament, and the above-mentioned middle yarn is Egyptian long-staple cotton and 60S / 2 cotton blended yarn composed of tencel, the above-mentioned base yarn is 55.5dtex spandex elastic yarn, and the above-mentioned cotton blended yarn is processed by the following processing steps:

[0074] (1) Spinning, selecting Egyptian long-staple cotton and tencel with an average length greater than 34mm, wherein the weight percentage of Egyptian long-staple cotton is 80%, and the weight percentage of Tencel is 20%, and ring spinning is carried out to it to obtain a count. Cotton blended yarn of count 60S / 2;

[0075] (2) Singeing. The hairiness on the surface of the cotton blended yarn 1 obtained in step (1) is uniformly removed by using ring burners 2 at 1500°C. The r...

Embodiment 3

[0097] A cotton-containing warp-knitted fabric, which is printed on the front and plain-colored on the reverse side, is made of top yarn, middle yarn and bottom yarn through warp knitting. The above-mentioned top yarn is 111dtex polyester semi-gloss flat filament, The above-mentioned middle yarn is a 100S / 2 cotton blended yarn made of Egyptian long-staple cotton and flax, and the above-mentioned base yarn is 33.3dtex spandex elastic yarn. The cotton blended yarn is processed by the following processing steps:

[0098] (1) Spinning, select Egyptian long-staple cotton and flax with an average length greater than 34mm, wherein the weight percentage of Egyptian long-staple cotton is 50%, and the weight percentage of flax is 50%, and they are compact spun to obtain a count of 100S / 2 cotton blended yarn;

[0099] (2) Singeing. The hairiness on the surface of the cotton blended yarn 1 obtained in step (1) is uniformly removed by using ring burners 2 at 1500°C. The ring burners 2 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com