Burr-proof thermoplastic polyurethane elastic body conveying belt for food industry and manufacture method thereof

A thermoplastic polyurethane, food industry technology, applied in conveyors, chemical instruments and methods, layered products, etc., can solve problems such as affecting production efficiency, taking a long time, food pollution, etc., to reduce meandering adjustment work, safe and reliable Conveying method, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

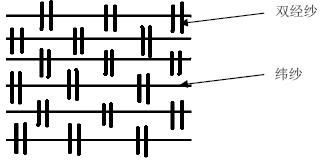

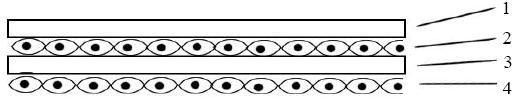

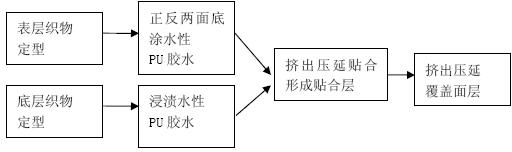

[0032] see figure 1 It is the organizational structure diagram and figure 2 As shown in the schematic cross-sectional structure of the TPU conveyor belt of the present invention, a kind of anti-flash thermoplastic polyurethane elastomer conveyor belt for the food industry is formed by laminating two layers of fabrics. The total thickness of the conveyor belt is 1.4mm. And the bottom includes: covering surface layer 1, surface layer fabric 2, bonding layer 3 and bottom layer fabric 4, wherein, surface layer fabric 2 and bottom layer fabric 4 are all formed by two warp yarns and a weft yarn plain weave, also can two warp yarns Insert one heddle without twisting at the same time, and interweave two warp yarns and one weft yarn in a plain weave structure. The warp yarns are 21 counts and 3 strands of polyester spun yarns with a density of 30-34 strands / inch. Low-shrinkage polyester monofilaments with a diameter of 0.2-0.3 mm are used, and the density is 24-28 per inch; the cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com