Filament short-fiber composite yarn

A short fiber and filament technology is applied in the field of filament and staple fiber composite yarns, which can solve the problems of prone to weft skew, affect the quality of the yarn, and the short fibers are easy to slip off, so as to enhance the bending rigidity and improve the spinning count. Number, the effect of enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

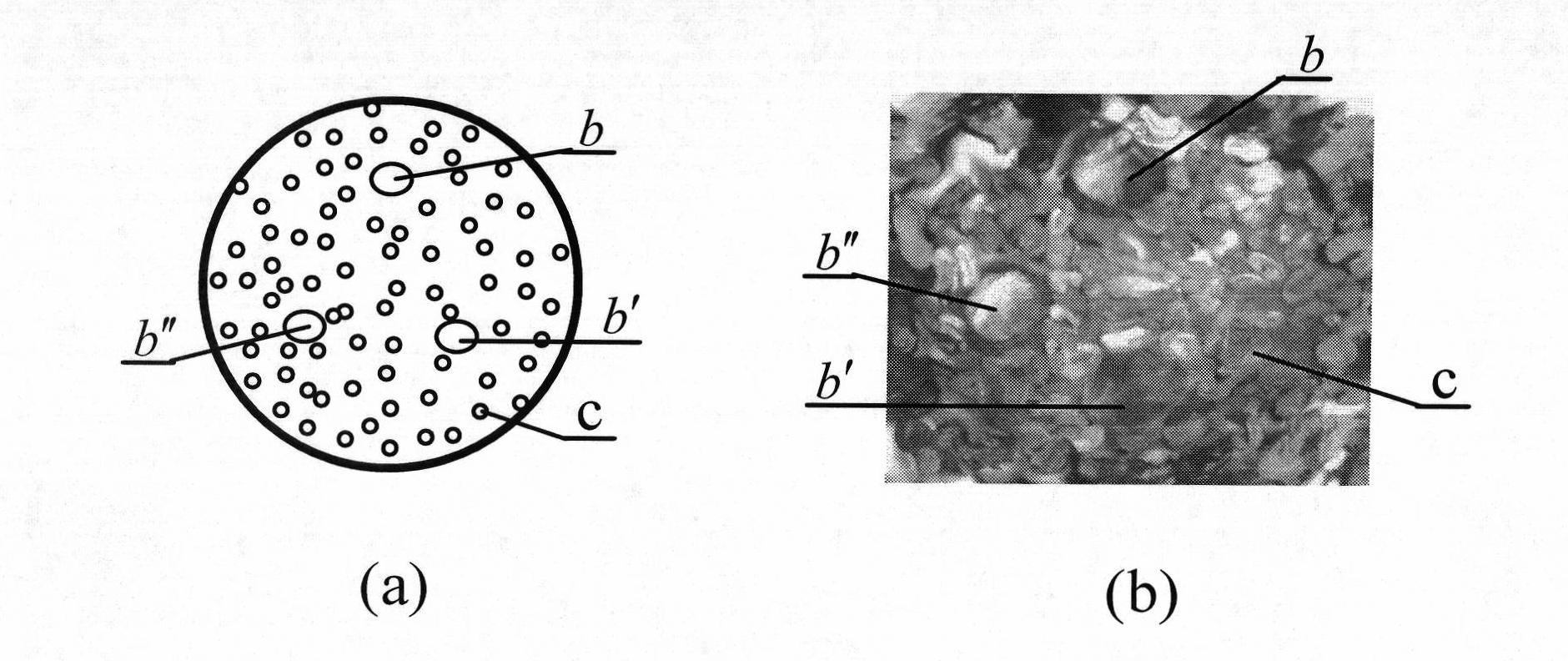

[0030] Embodiment 1, the composite structure yarn of cotton fiber coating polyester filament (monofilament)

[0031] Such as figure 1 (a), (b), figure 2 Composite yarn patterns shown in (a) and (b), the yarn is made by Figure 5 and Figure 5A In the process shown, on the cotton spinning ring spinning frame, the cotton fiber roving sliver a is unwound from the roving bobbin, passed through the guide horn 1 and fed into the drafting zone by the back roller 2, and three polyester filaments (12D / 1F ) b, b', b" are respectively guided by the positioning wire guide mechanism and fed in parallel from the rear end of the front roller 5 at a distance of 0.5mm. Port 6 converges, and the three filaments b, b', b" are all located within the width boundary of the roving strands (see Figure 6 ), after drafting, the cotton roving strip a and filaments b, b', b" are output from the front jaws and enter the twisting triangle area, and the composite yarn 8 formed after twisting is wound ...

Embodiment 2

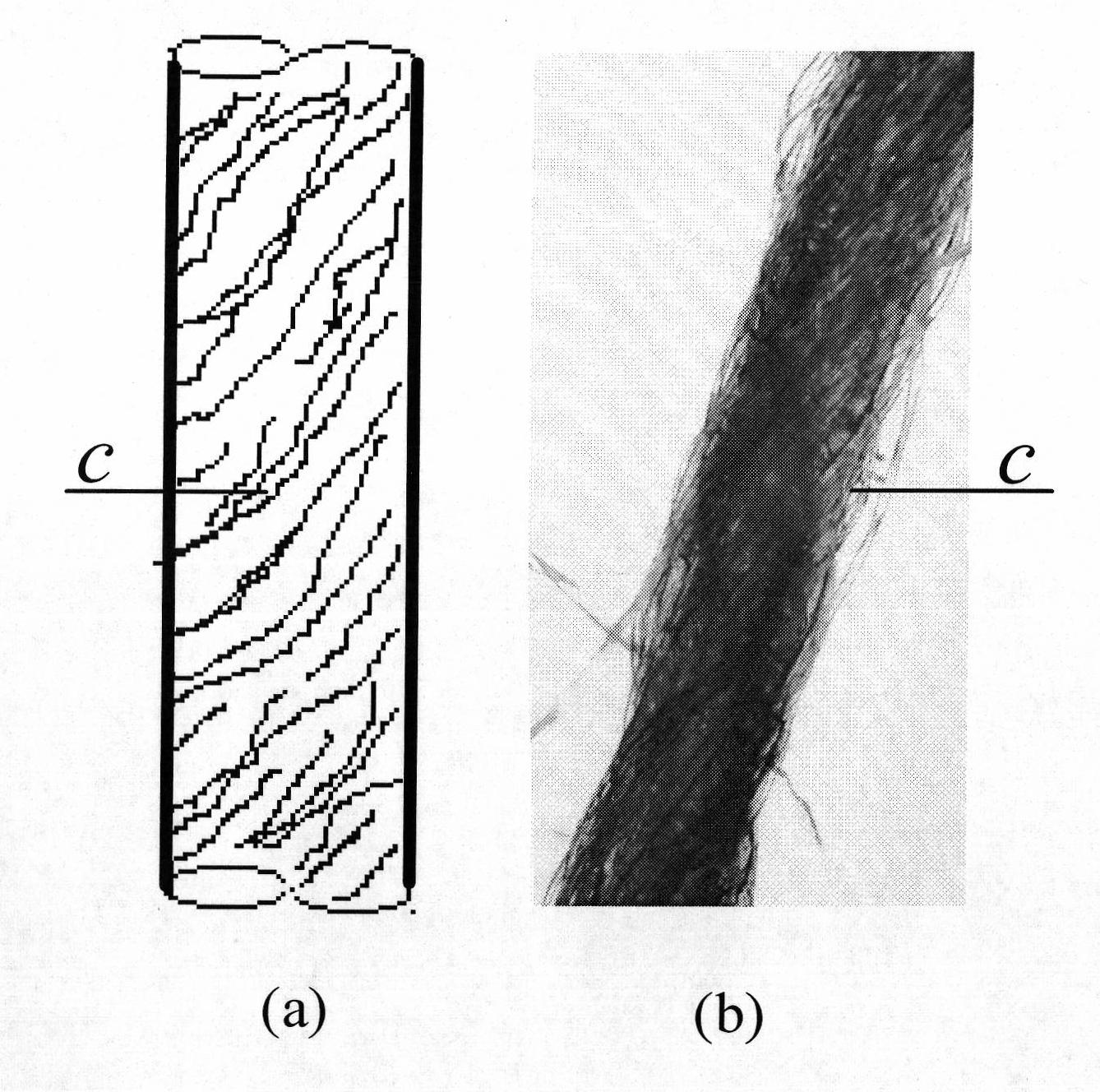

[0033] Embodiment 2, make the composite yarn that polyester filament (monofilament) wraps cotton short fiber

[0034] Such as image 3 (a), (b), Figure 4 Composite yarn patterns shown in (a) and (b), the yarn is made by Figure 5 and Figure 5A In the process shown, on the cotton spinning ring spinning frame, the cotton fiber roving sliver a is unwound from the roving bobbin, passed through the guide horn 1 and fed into the drafting zone by the back roller 2, and three polyester filaments (12D / 1F ) b, b', b" are respectively guided by the positioning guide mechanism and fed in parallel from the rear end of the front roller 5 at a distance of 2mm. 6 confluence. Wherein, the polyester filament b is located outside the width boundary range of the roving bar a, and the polyester filaments b' and b" are respectively located inside the width boundary range of the roving bar a (see Figure 7 ), after drafting, the cotton roving strip a and filaments b, b', b" are output from th...

Embodiment 3

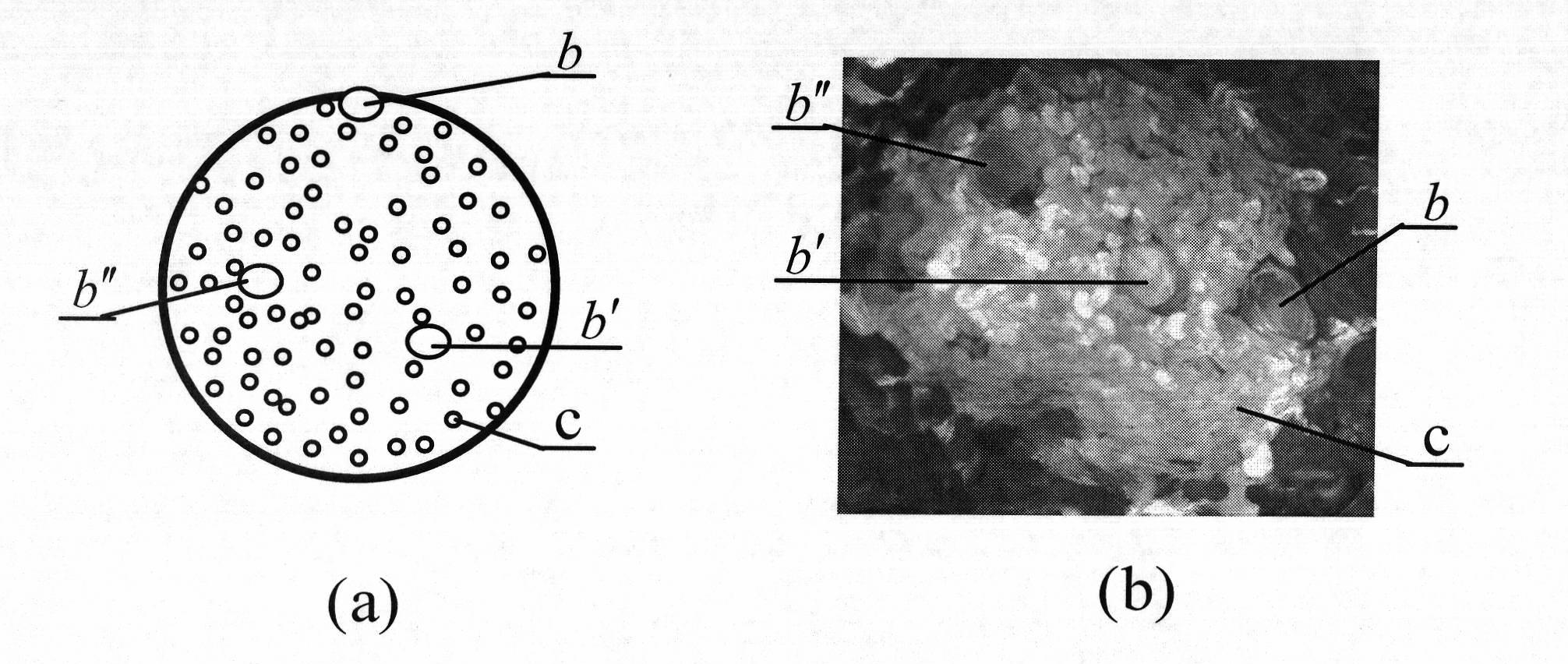

[0036] Embodiment 3, making metal filament cotton fiber special yarn

[0037] With the continuous development of fiber processing technology, the processing technology of special yarn has become an important direction of textile processing. Fabrics made of special yarn are widely used in national defense, military industry, anti-static, anti-electromagnetic radiation and other fields. At present, the special yarns are mostly blended, and the ingredients are mostly polyester, cotton, metal fibers, etc. This example uses metal filaments and cotton fibers as raw materials to process special composite yarns of metal filaments and cotton fibers.

[0038] Such as figure 1 (a), (b), figure 2 Composite yarn patterns shown in (a) and (b), the yarn is made by Figure 5 and Figure 5A In the process shown in the figure, on the cotton ring spinning frame, the cotton fiber roving strand a is unwound from the roving bobbin, passed through the guide horn 1 and fed into the drafting zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com