Method for improving felting resistance and pilling resistance of animal fibers or fabric thereof

An anti-pilling and animal fiber technology, which is applied in fiber treatment, textile and papermaking, physical treatment, etc., can solve the problems of uneven treatment, limit large-scale production, increase consumer burden, etc., and achieve improved treatment efficiency and uniformity It is easy to promote and apply in industrialization, and has the effect of wide adaptability of fabric varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

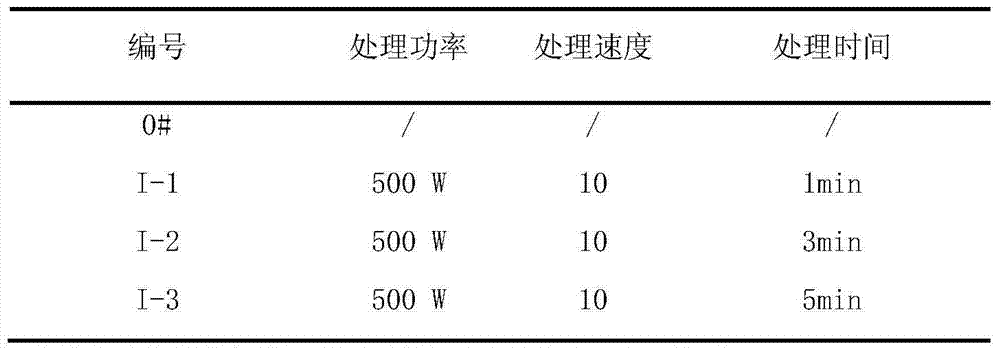

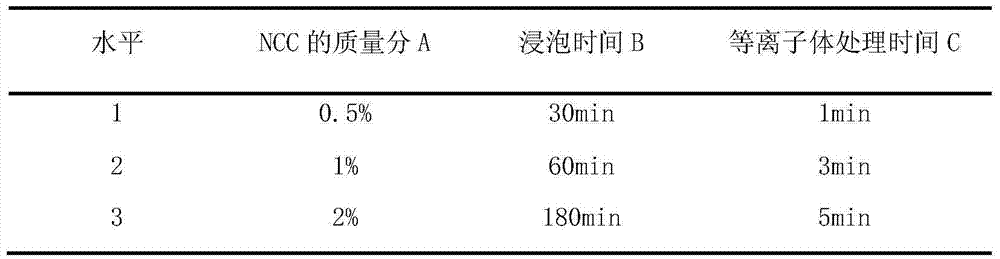

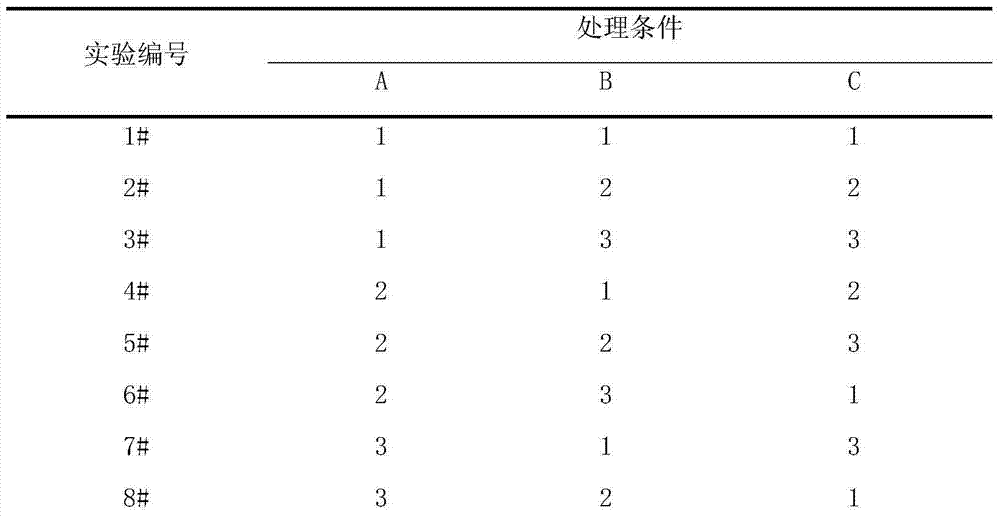

Method used

Image

Examples

Embodiment Construction

[0053] Below by embodiment the present invention will be further described. It should be understood that the methods described in the examples of the present invention are only used to illustrate the present invention, rather than to limit the present invention, and any simple improvement to the preparation method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

[0054] All the raw materials and solvents used in the examples are commercially available analytically pure, the rabbit hair fiber and its fabric are provided by Zhejiang Shenzhou Wool Textile Co., Ltd., and the double quartz medium atmospheric pressure air plasma treatment equipment is provided by Jiaxing Quality Inspection Institute.

[0055] 1. Rabbit hair fiber and its fabric pre-drying:

[0056] Since the surface of rabbit hair fiber and its fabric contains less oil, about 0.6% to 0.7%, it does not need to be cleaned, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com