Low-temperature negative pressure drying method and device for textile materials and textiles

A textile material, low temperature negative pressure technology, used in the combination of medium and small power microwave sources, vacuum negative pressure drying field, can solve the problem of reduction, achieve the effect of wide application, fast drying process and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

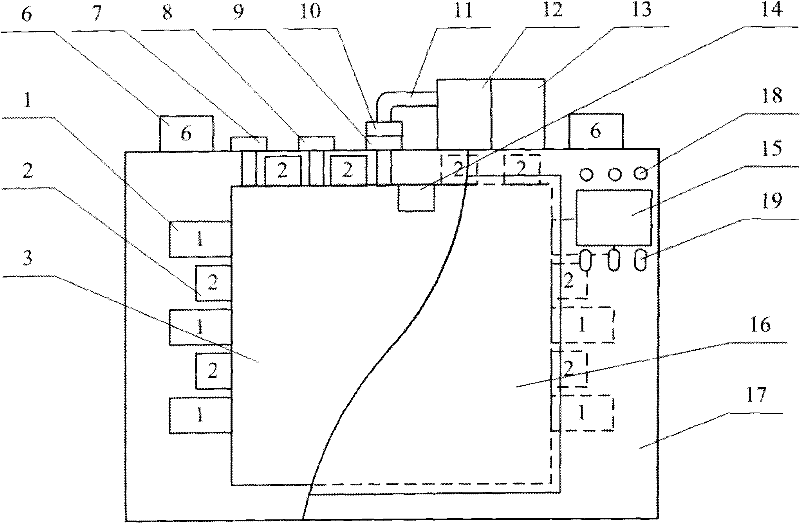

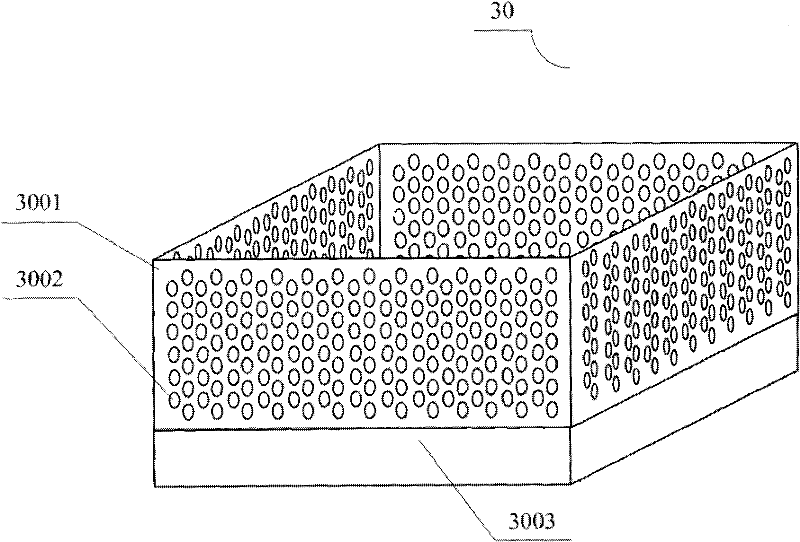

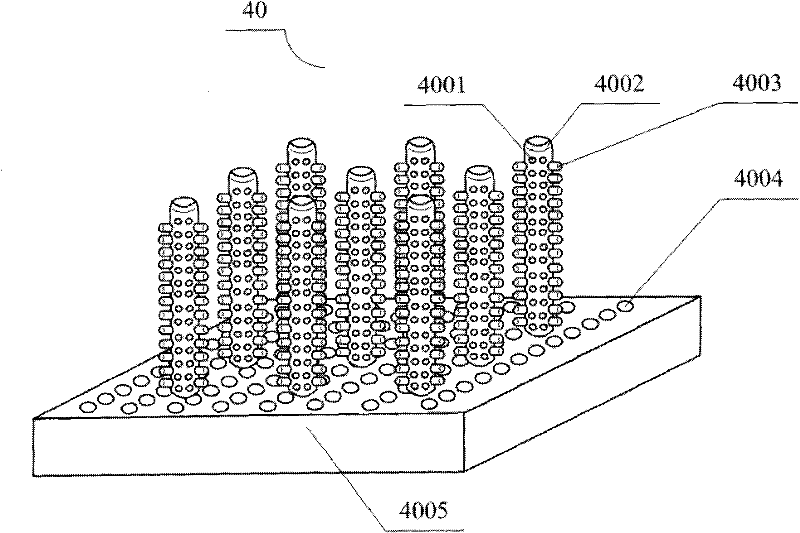

[0038] see figure 1 , figure 2 with image 3 , the said device for low-temperature negative pressure drying of textile materials and textiles consists of a microwave source 1, a temperature sensor 2, a resonant cavity 3, an air-cooled or water-cooled device 6, a vacuum sensor 7, an air release valve 8, a humidity sensor 9, Air extraction valve 10, air extraction pipeline 11, vacuum pump 12, vacuum pump motor 13, agitator 14, panel and controller 15, shielding airtight door 16, shell 17, indicator light 18, switch 19, bulk goods drying box 30 and bobbins Yarn drying bracket 40, wherein, in the shell 17, several microwave sources 1 composed of small and medium power magnetrons, excitation chambers, waveguides and power supplies are distributed on the wall of the resonant cavity 3, and together form the resonant cavity 3 A microwave heating device with a uniform temperature field; the heat emitted by the microwave source 1 itself is dissipated by an air-cooled or water-cooled ...

Embodiment 2

[0043] see Figure 4 , Figure 4 It is a small low-temperature negative pressure drying device for sample drying, which consists of microwave source 1, temperature sensor 2, resonant cavity 3, air cooling or water cooling device 6, vacuum sensor 7, air release valve 8, humidity sensor 9 , exhaust valve 10, exhaust pipeline 11, vacuum pump 12, vacuum pump motor 13, panel and controller 15, indicator light 18, switch 19, inner shell 20, airtight door 21, screen door 22, outer shell 23 and partition plate 24 Among them, in the shell 23, several microwave sources 1 composed of small and medium power magnetrons, excitation chambers, waveguides and power supplies are distributed on one side of the resonant cavity 3, and together with the resonant cavity 3 constitute a microwave heating device, the microwave source 1 The heat emitted by itself is dissipated by the air-cooling or water-cooling device 6; the inner shell 20, the airtight door 21 and the partition plate 24 are all made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com