Surface treatment method of fabric

A technology for products and textiles, applied in the field of surface treatment of spinning fiber products, can solve the problems of unstable operation, difficult composite functionality, water stains on spinning fiber products, etc., to reduce energy and labor consumption, improve Fastness to washing, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

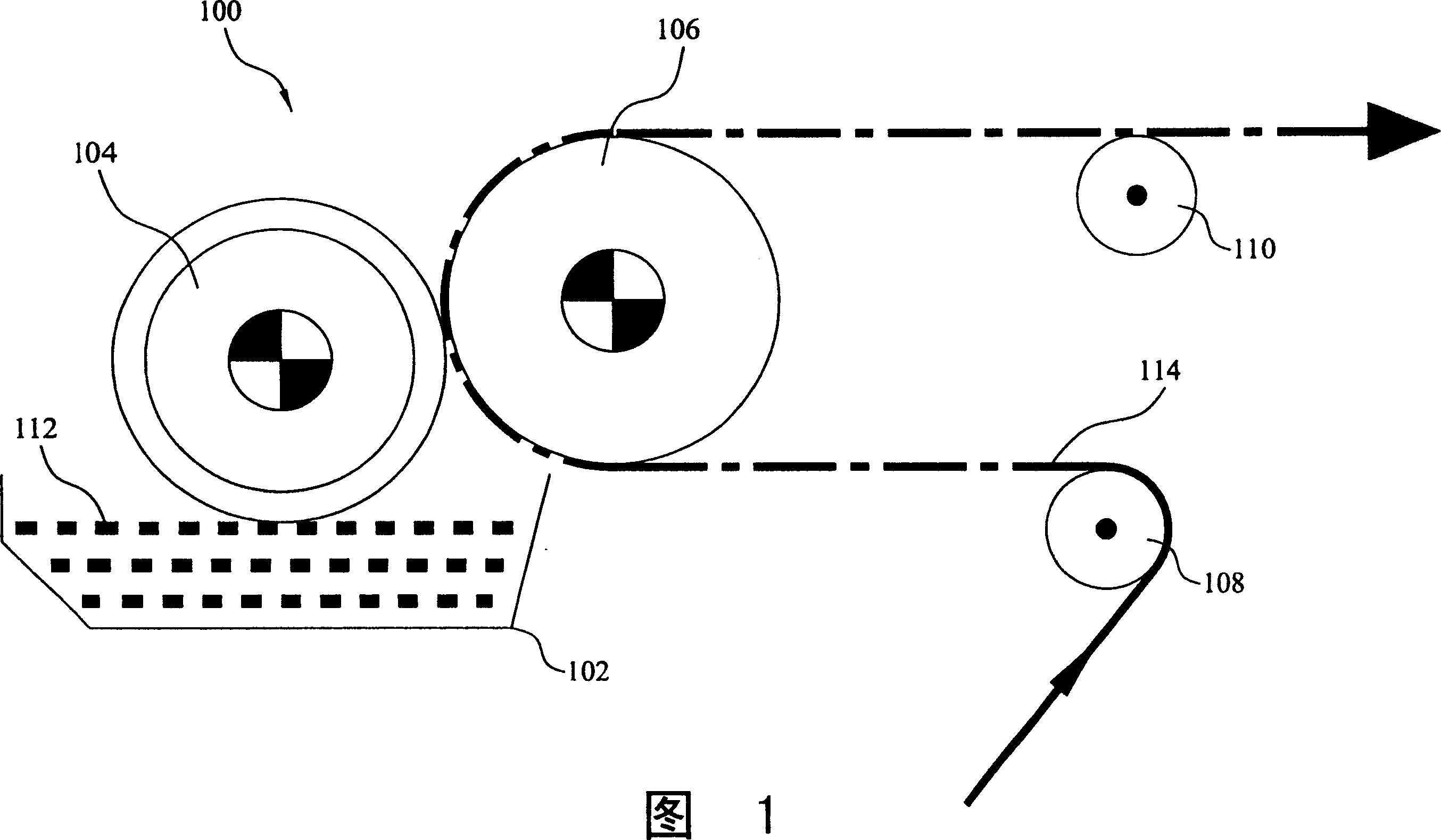

[0019] Please refer to FIG. 1 . FIG. 1 is a schematic diagram of a gravure coating surface treatment device disclosed in the present invention. The gravure printing equipment 100 at least includes a tank body 102 , a gravure printing roll (Gravure Roll) 104 , a pressure roll 106 and guide rolls 108 , 110 . Choose to use polymers with bridging groups to form a coating liquid 112 with different functions, such as hydrophobicity, antibacterial or hydrophilic (moisture absorption), and place it in a tank 102 with an opening, wherein the coating liquid 112 uses The solvent can be alcohols or water. The gravure printing roller 104 is disposed above the tank body 102 , and the pressure roller 106 is disposed on the side of the gravure printing roller 104 . Textiles 114 that need to be surface treated pass between the gravure printing roller 104 and the pressure roller 106 through the guide of the guide wheel 108, and then the textile 114 enters a drying device (not shown in the figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com