Painting room for treating VOCs waste gas

A paint room and exhaust gas technology, applied in the direction of using liquid separation agent, dispersed particle filtration, dispersed particle separation, etc., can solve the problems of unpurified working environment and excessive dust VOCs at the discharge port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

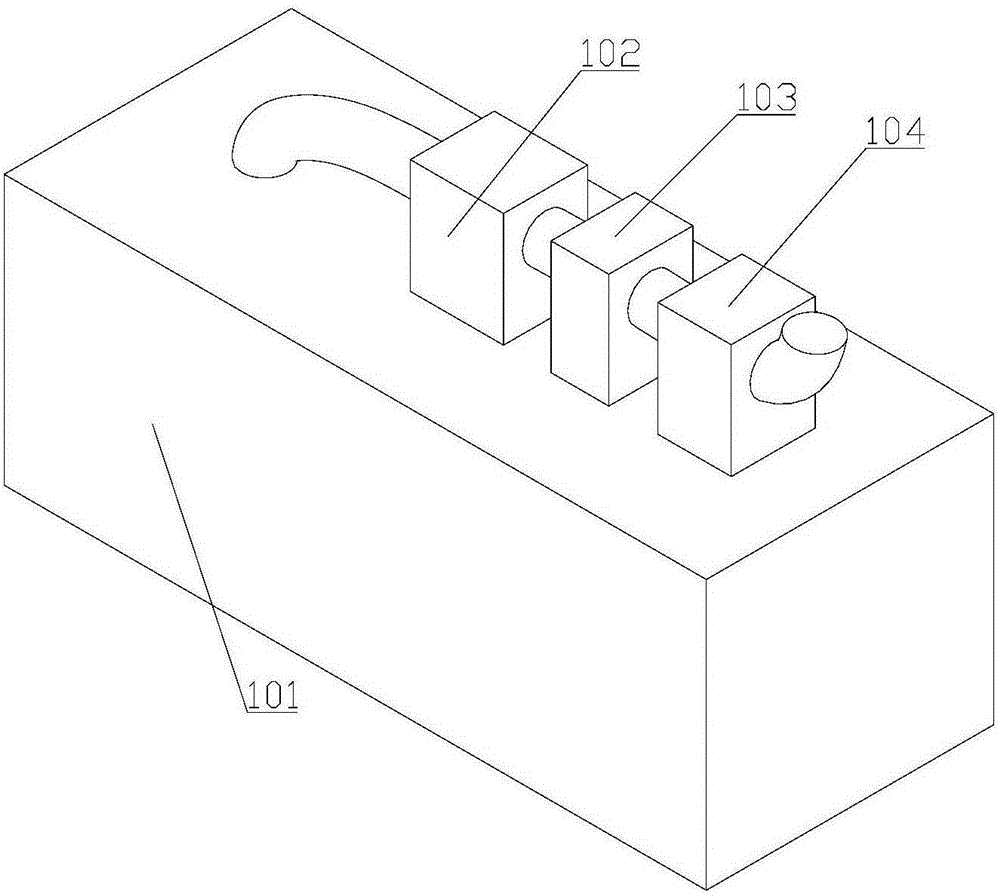

[0030] refer to figure 1 , the present embodiment provides a paint booth for treating VOCs exhaust gas, including: a paint booth main body 101, an exhaust gas treatment assembly, and an air introduction assembly 104, and the air introduction assembly 104 and the exhaust gas treatment assembly are all arranged outside the paint booth main body 101, The exhaust gas in the main body 101 of the paint booth can pass through the exhaust gas treatment assembly and the air introduction assembly 104 in turn. The exhaust gas treatment assembly includes an ultraviolet treatment box 102 and a plasma treatment box 103 connected to each other. The main body of the paint room can be made of rock wool board, and the connecting structural parts can be made of galvanized steel plate, so as to maintain good fire resistance and strength, and can also prevent the problem of being corroded by organic waste gas.

[0031] The working process of the paint room is as follows:

[0032] Workers carry ou...

Embodiment 2

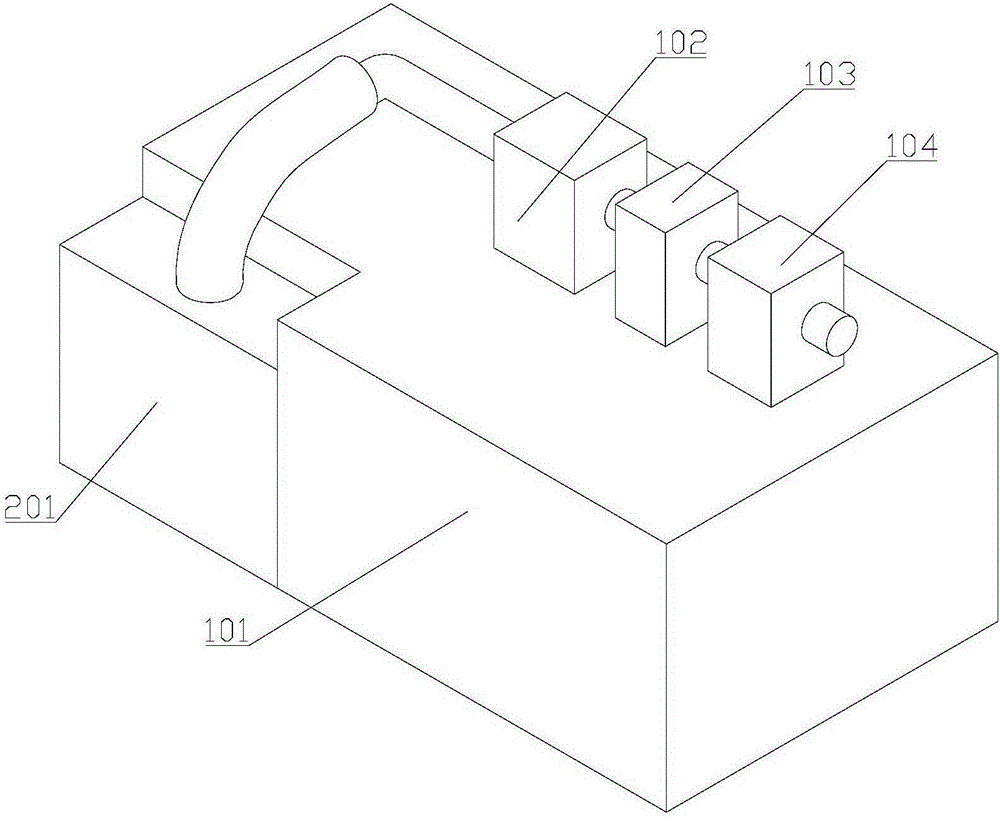

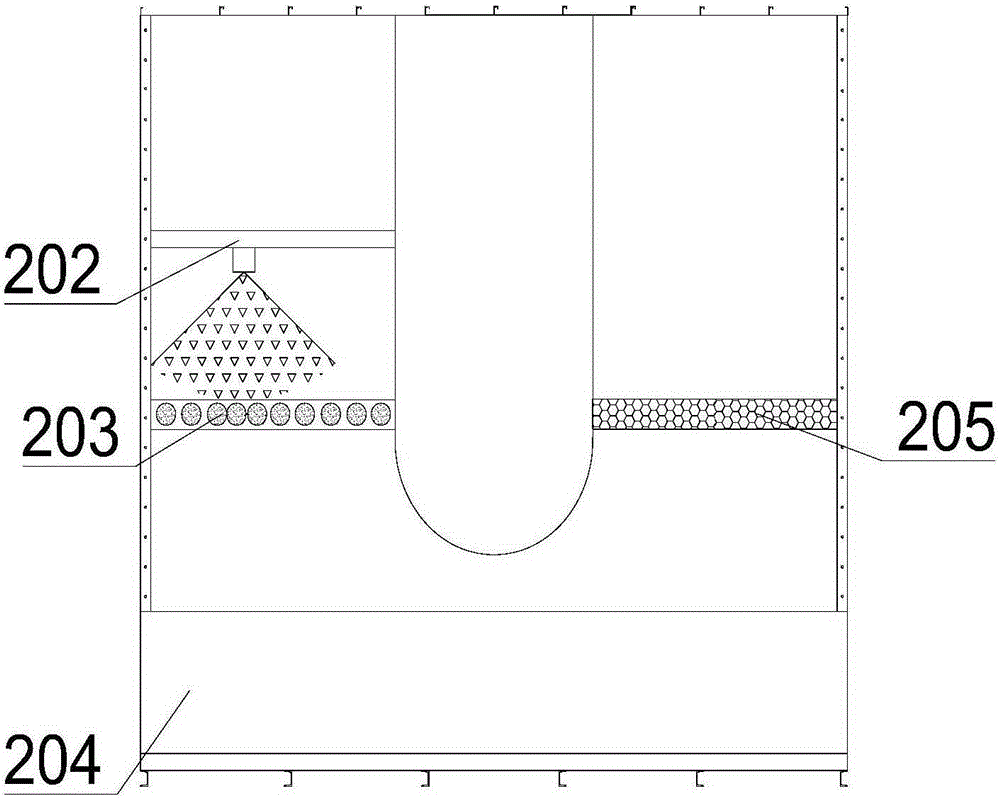

[0035] refer to figure 2 , image 3, the present embodiment provides a paint booth for treating VOCs exhaust gas, including: a paint booth main body 101, an exhaust gas treatment assembly, and an air introduction assembly 104, and the air introduction assembly 104 and the exhaust gas treatment assembly are all arranged outside the paint booth main body 101, The exhaust gas in the main body 101 of the paint booth can pass through the exhaust gas treatment assembly and the air introduction assembly 104 in turn. The exhaust gas treatment assembly includes an ultraviolet treatment box 102 and a plasma treatment box 103 connected to each other.

[0036] Due to the relatively large amount of dust in the paint room, the dust may also contain some polluting harmful substances. If the dust cannot be removed, it may cause certain damage to the environment and human body after discharge. Therefore, it is necessary to remove the dust in the exhaust gas. For example, the paint room is e...

Embodiment 3

[0041] refer to Figure 4 , the present embodiment provides a paint booth for treating VOCs exhaust gas, including: a paint booth main body 101, an exhaust gas treatment assembly, and an air introduction assembly 104, and the air introduction assembly 104 and the exhaust gas treatment assembly are all arranged outside the paint booth main body 101, The exhaust gas in the main body 101 of the paint booth can pass through the exhaust gas treatment assembly and the air introduction assembly 104 in turn. The exhaust gas treatment assembly includes an ultraviolet treatment box 102 and a plasma treatment box 103 connected to each other.

[0042] Furthermore, the paint room used to treat VOCs exhaust gas also includes a scrubber, which is used as the main place for dust removal to clean up the dust in the exhaust gas. The washing tower is respectively connected with the main body 101 of the paint booth and the waste gas treatment component. The waste gas in the paint room enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com