Medical waste microwave treatment method and treatment equipment

A medical waste and microwave treatment technology, applied in the microwave field, can solve the problems of smoke pollution, easy emission, long time required, etc., and achieve the effect of reducing output, realizing discharge and safe discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

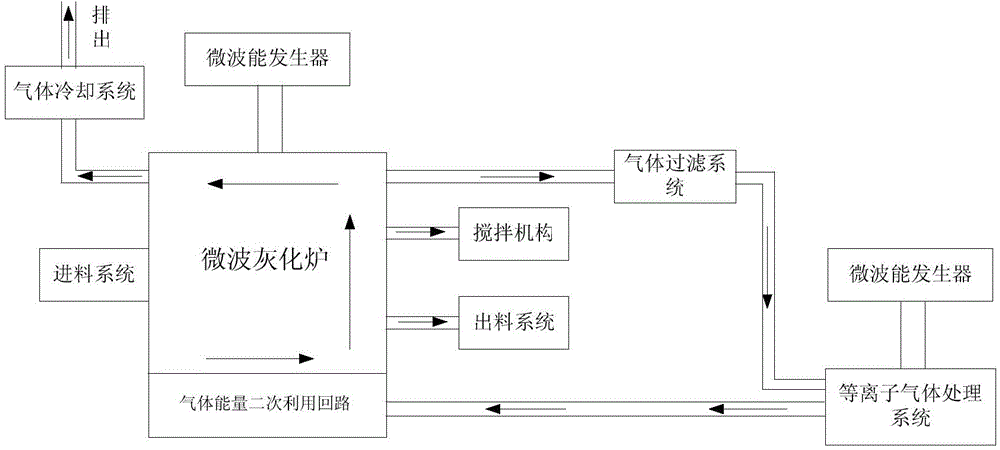

[0009] Microwave treatment of medical waste

[0010] A microwave treatment method for medical waste of the present invention specifically comprises the following steps:

[0011] Step 1. Use the medical waste feeding system to send the medical waste into the microwave ashing furnace;

[0012] Step 2: Use a microwave energy generator to generate microwave power in the microwave ashing furnace to incinerate medical waste, so that medical waste can be quickly ashed;

[0013] Step 3. In the process of incinerating medical waste, use a stirring system to stir the medical waste to fully separate the medical waste from the ashes formed by ashing, so that the medical waste can be incinerated more fully;

[0014] Step 4. During the process of incinerating medical waste, use the discharge system to timely clean the ashes from the ashing of medical waste out of the wave ashing furnace cavity and enter the ash collection device to improve the processing efficiency;

[0015] Step 5. The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com